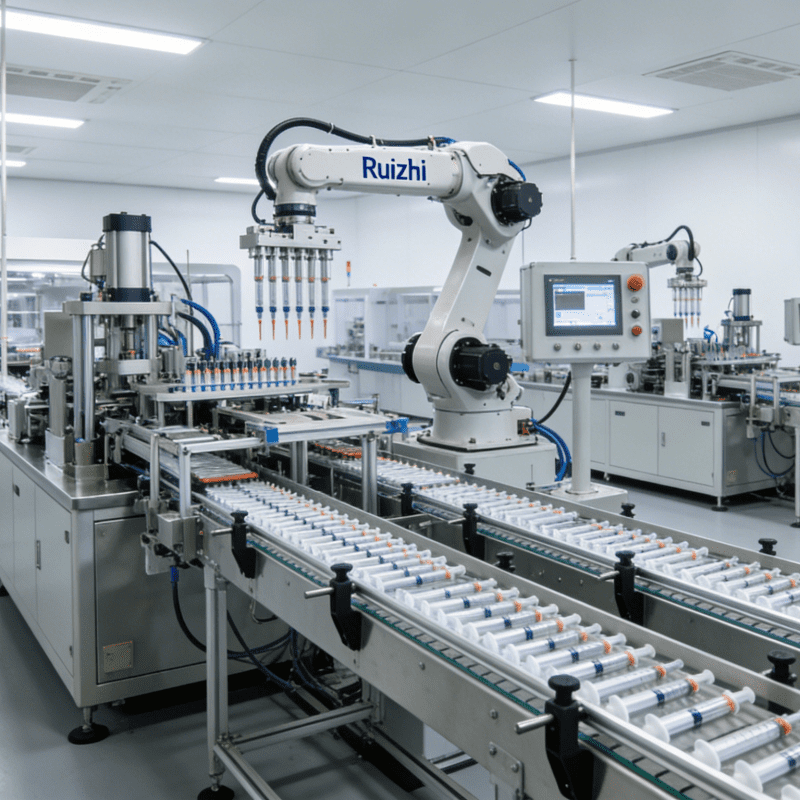

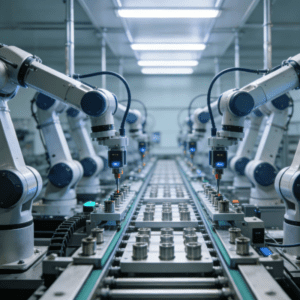

In the fast-growing medical device industry, nebulizers play a critical role in respiratory treatment, requiring strict assembly precision, stability, and compliance. Standard equipment often fails to meet the diverse specifications and high-quality demands of modern medical manufacturing. Ruizhi Intelligent Manufacturing focuses on non-standard automation solutions, providing high-precision nebulizer assembly equipment designed for medical-grade production. Our fully integrated assembly lines help manufacturers improve efficiency, ensure consistency, and meet global regulatory requirements.

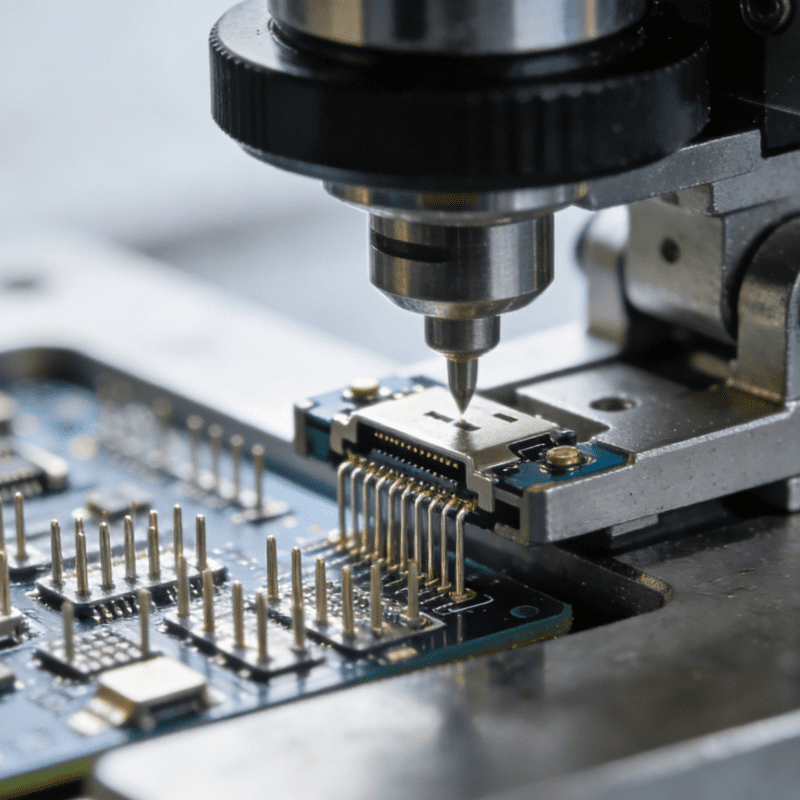

Sub-Micron Precision for Medical-Grade Consistency

Medical nebulizers demand extremely tight assembly tolerances to guarantee reliable atomization, air tightness, and long service life. Our high-precision nebulizer assembly machine uses servo-driven positioning, precision fixtures, and real-time force control to maintain assembly accuracy within ±0.02 mm. Key processes including nozzle installation, sealing ring placement, shell fitting, and pressure testing are fully automated and monitored. Equipped with high-resolution vision inspection, the system detects misalignment, defects, and incomplete assembly in real time, ensuring 100% compliance with medical standards. By minimizing human error, Ruizhi’s equipment delivers stable, repeatable performance essential for mass production of safe and reliable nebulizers.

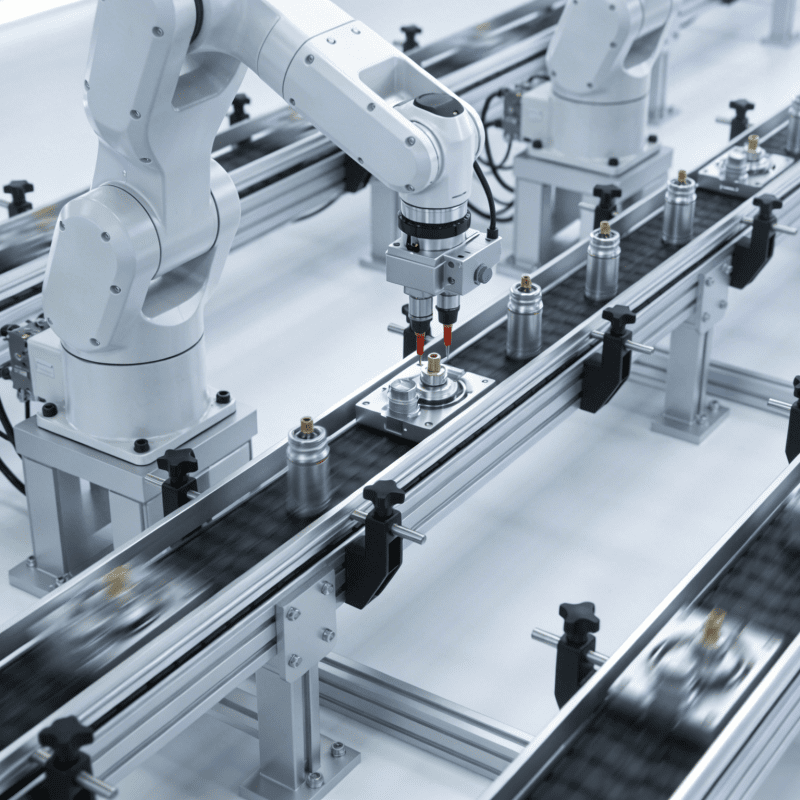

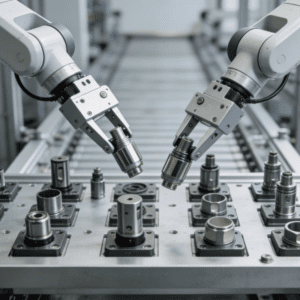

Non-Standard Customization for Diverse Nebulizer Models

Different nebulizer designs—including mesh nebulizers, jet nebulizers, portable and household models—feature varied structures, sizes, and assembly sequences. As a professional non-standard automation provider, Ruizhi Intelligent Manufacturing offers fully customized solutions tailored to your product specifications. We design modular stations, adaptable tooling, and flexible transmission systems to support multi-model production on one line. Whether you need to assemble small nozzles, complex inner structures, or special-shaped shells, our equipment can be adjusted quickly with minimal downtime. This high adaptability helps medical manufacturers reduce investment, simplify production management, and accelerate product upgrades.

High Efficiency & Stability for Scalable Medical Production

Efficiency and reliability are vital in medical device manufacturing. Ruizhi’s nebulizer assembly machine integrates automatic feeding, precise assembly, online inspection, leak testing, and finished product sorting in one continuous flow. The fully automated line greatly reduces manual labor while achieving stable output suitable for 24-hour uninterrupted production. The robust frame, premium components, and intelligent fault self-diagnosis system ensure low failure rates and easy maintenance. Additionally, our equipment supports production data recording and traceability, helping customers meet audit requirements of ISO 13485, CE, and FDA. With optimized design, the line delivers high output with consistent quality, supporting manufacturers to scale production while strengthening market competitiveness.

Ruizhi Intelligent Manufacturing remains committed to innovative non-standard automation for the medical industry. Our high-precision nebulizer assembly machine combines accuracy, customization, and efficiency to support global medical device manufacturers. We continue to provide reliable, future-proof automation solutions that enhance product quality and drive intelligent production upgrades.