Driven by the integration and innovative application of new-generation information technologies such as the Internet of Things and big data, the Hangzhou Municipal Construction Commission is promoting the agglomeration of various advanced production factors in the construction field towards the development of new productive forces.

In recent years, the Hangzhou Municipal Construction Commission has earnestly implemented the Guiding Opinions on Promoting the Coordinated Development of Intelligent Construction and Building Industrialization issued by the Ministry of Housing and Urban-Rural Development and other departments, as well as the decisions and arrangements of the municipal Party committee and government on the optimization and upgrading of traditional industries and digital and intelligent transformation. Driven by the integration and innovative application of new-generation information technologies such as the Internet of Things, big data, cloud computing, and artificial intelligence, it has made continuous efforts in intelligent design, intelligent production, intelligent construction, intelligent management, and intelligent operation and maintenance, and fully promoted the “Hangzhou Model” of in-depth integration of AI technology and the construction industry. This promotes the agglomeration of various advanced production factors in the construction field towards the development of new productive forces, providing practical experience for the development of intelligent construction across the country.

Cognitive Renewal in the Design Link

The essence of AI design tools is to transform architectural professional knowledge into computable models, breaking through the limitations of manual experience. This cognitive revolution realizes the dual improvement of design efficiency and quality through the technical path of “standard datamation – design intellectualization – result standardization”. To this end, the Municipal Construction Commission has formulated the Three-Year Plan for the Development of Hangzhou’s Survey and Design Industry (2023 – 2025) and issued the Pilot Plan for the Whole-Life Cycle Digital Management Reform of Engineering Construction Projects in Hangzhou, etc., to promote and guide leading design enterprises and construction enterprises to explore and study the whole-process intelligent BIM model driven by AIGC, so as to realize the innovative application of AI technology in the field of architectural design.

Projects such as the Hangzhou Canal Asian Games Park designed by PowerChina Huadong Engineering Corporation Limited and the Zijin Zhunqian Scientific Research Building designed by the Architectural Design and Research Institute of Zhejiang University have organically combined BIM technology and AI technology in the design stage, carrying out applications such as building performance analysis and simulation, multi-scheme comparison and selection, design optimization, cost and engineering quantity statistics, construction simulation, and VR display, so as to realize the whole-process and all-round information integration of the “five-in-one” construction industry chain including design, production, construction, manufacturing, and management.

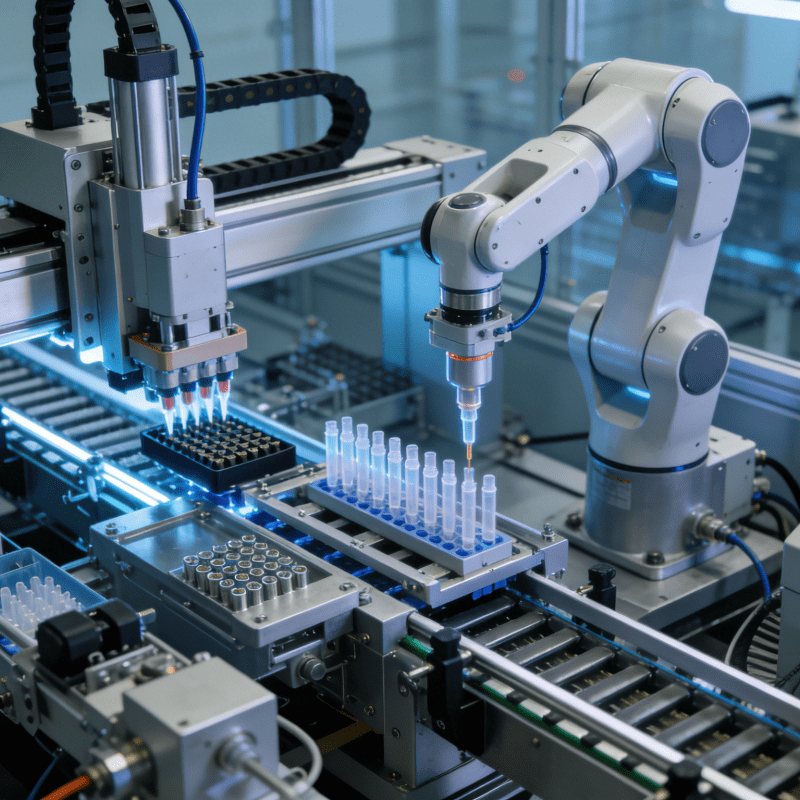

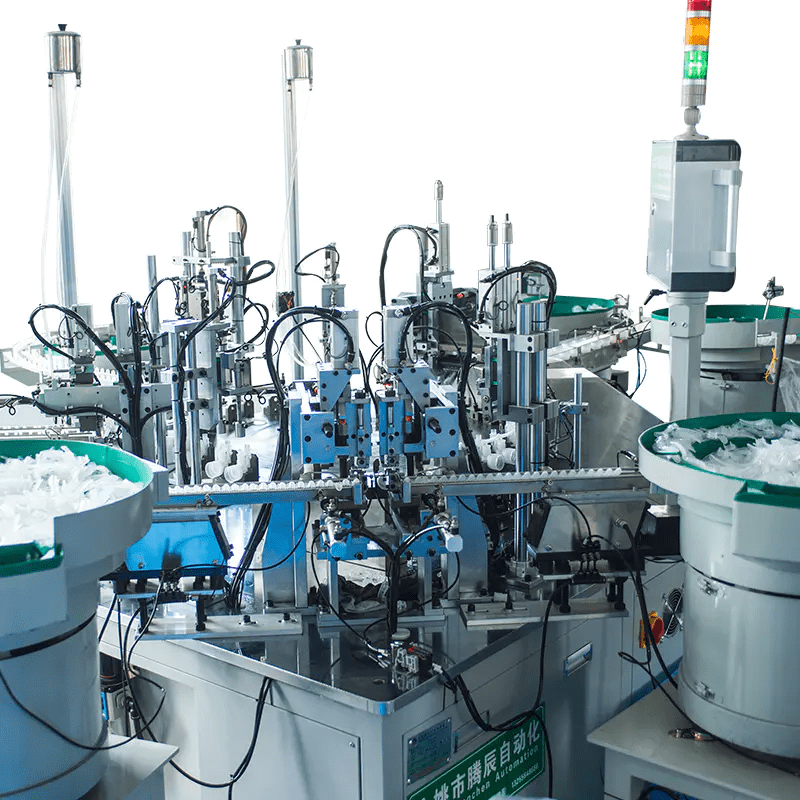

Iterative Upgrade in the Production Link

By issuing the Implementation Opinions on Continuously Promoting the Development of Prefabricated Buildings and implementing policy measures such as promoting excellence and awards, financial subsidies, and green finance, the Municipal Construction Commission encourages and promotes prefabricated components and parts to apply BIM data-driven intelligent production lines, effectively connecting the design, construction, and production links. Through IoT and AI technologies, it promotes the online linkage of production equipment, realizing automatic production scheduling and standardized production in prefabricated production enterprises. Among them, some prefabricated component production enterprises have introduced the Automatic Iron Rod Loading Unloading System, which realizes the automatic feeding of steel raw materials and the accurate stacking of finished products after cutting through the collaboration of intelligent sensors and robotic arms. This not only reduces the labor cost by more than 60% but also controls the material loss rate within 1% through standardized operations, greatly improving the efficiency and accuracy of the production link.

The steel structure MES intelligent production and construction system of Zhejiang Southeast Space Frame Co., Ltd. uses AI algorithms to intelligently control the amount of raw materials and adopts intelligent terminals to collect production logistics information, ensuring the efficiency and intelligence of production.

The “Research and Application of Integrated Technical System for Design and Manufacturing of Steel Structure Prefabricated Buildings” by Haner 姆 Construction Technology Co., Ltd. integrates BIM technology, AI technology with information platforms such as ERP and MES, connecting all links in the whole life cycle of prefabricated interior decoration design, production, construction, and operation and maintenance, realizing the whole life cycle management of buildings and the green and recyclable use of parts and components.

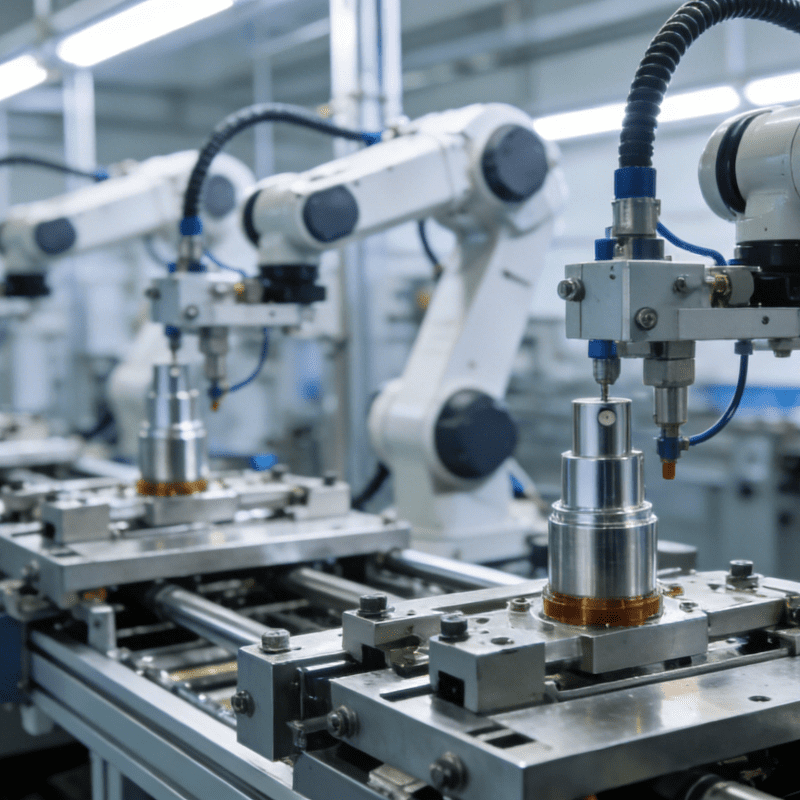

Technological Revolution in Construction Methods

With the continuous development of AI and robot technology, construction robots and advanced intelligent equipment have successively entered the construction site and become an important part of intelligent construction. To this end, the Municipal Construction Commission has accelerated the development of intelligent construction industry chains through intelligent construction pilot projects, promoting key core technology research and technological innovation in intelligent construction.

The “Research and Application of Intelligent Question-Answering System for Building Construction Based on AIGC Technology” developed by Zhejiang Construction Investment Innovation Technology Co., Ltd. innovatively introduces knowledge standard answer mode, standardized hierarchical optimization index, and image table entry logic trigger mechanism, with functions such as intelligent speech recognition and transcription, accurate intention recognition, high answer accuracy, and rapid export of background data, providing decision-making assistance for engineering and technical personnel.

The project of Xiaozhengchu [2021] No. 33 plot constructed by China Construction Eighth Engineering Division Co., Ltd. applies the independently developed “Tianchan” residential construction robot system, which integrates five systems: self-climbing system, distributed intelligent construction system, lightweight operation platform, operation enclosure system, and intelligent monitoring system. It has multiple advantages such as lightweight, modularization, assembly, platformization, intelligence, and greenization, realizing the whole chain intelligence of construction technology and creating a new mode of group intelligent construction.

Practice has proved that the application of construction robots and advanced intelligent equipment has greatly improved construction efficiency, saved labor costs, reduced the safety risks of manual operations in high-risk environments, and improved project quality.

Full-Link Empowerment of Smart Construction Sites

Smart construction sites realize the intelligent collaboration of engineering elements by building a “digital twin” management system. Its theoretical innovation lies in establishing a PDCA (Plan – Do – Check – Act) closed-loop management and control mechanism, promoting the evolution of engineering management from discrete control to systematic governance. The Municipal Construction Commission takes the “Zhejiang Engineering Construction Digital Management System” as a platform to promote the integrated application of smart construction sites, integrating more than 10 application scenarios such as automatic foundation pit monitoring and remote AI video monitoring, and editing the Zhejiang Provincial Engineering Construction Standard “Smart Construction Site Construction Standard”.

Based on massive engineering data training and technical iteration of the visual large model, Pinming Technology Co., Ltd. independently developed visual AI recognition technology, built an “air + ground” three-dimensional perception network, which is applied to the real-name system contactless attendance, personnel safety supervision, and environmental monitoring systems of multiple engineering projects.

The Zhejiang University Zijin Port Campus Construction Project of Zhejiang Construction Engineering Group Co., Ltd. applies the “AI-based UAV – Robot Construction – Operation and Maintenance Full-Cycle Automated Inspection Application”, introducing a quadruped robot platform, integrating digital twin, AI vision, and multi-modal perception technologies, building an intelligent inspection system for the whole cycle of construction – operation and maintenance, covering core links such as trajectory planning, danger identification, quality inspection, and defect diagnosis.

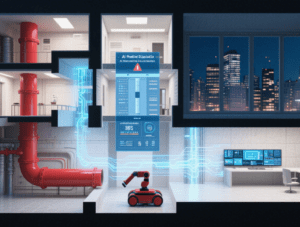

Sustainable Upgrade of Building Operation and Maintenance

The smart operation and maintenance system realizes the intelligent control closed-loop of “perception – analysis – decision-making” by building a digital mapping of building energy metabolism. The Municipal Construction Commission takes CIM as the entry point to explore the innovative application of AI technology in intelligent operation and maintenance. At present, the Hangzhou CIM platform has completed the third-phase development task, collecting 19 categories and 90 subcategories of urban data, and realizing more than 10 “CIM+” application scenarios such as intelligent protection of engineering geological survey, intelligent prevention of underground space hidden dangers, and special applications for urban renewal.

In the next step, the Municipal Construction Commission will dig deep into the application scenarios of intelligent construction and BIM, promote the real-time data intercommunication between intelligent equipment, building information models (BIM), and city information models (CIM) platforms in the city’s under-construction sites, explore the in-depth integration of big data, AI models in the construction field with CIM platforms, and promote the full amount of data governance of engineering projects and the construction of digital twin cities.