The lip gloss applicator, as a core component affecting user experience, has strict requirements for assembly precision and consistency. Traditional manual assembly faces pain points such as low efficiency, high error rate and rising labor costs. Ruizhi Intelligent Manufacturing’s Fully Automated Lip Gloss Applicator Assembly Machine integrates multiple processes with intelligent technology, creating a stable and efficient production solution for cosmetic enterprises. It redefines the assembly standard of lip gloss applicators and empowers brands to achieve high-quality mass production.

Break Through Efficiency Bottlenecks

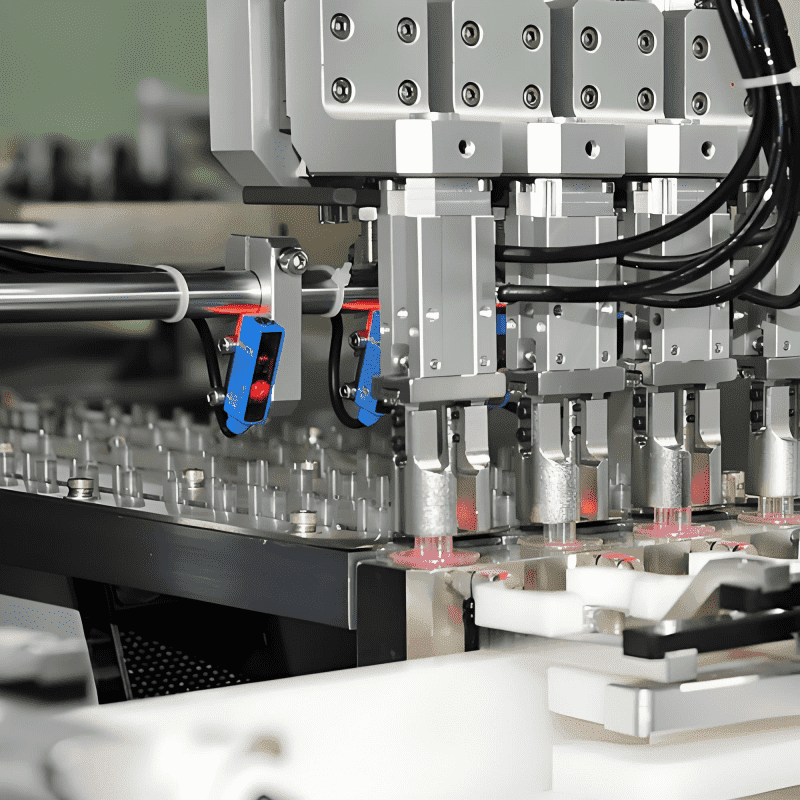

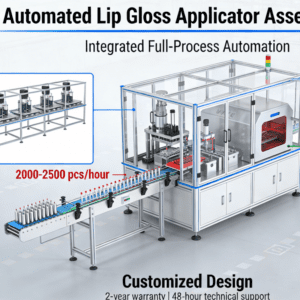

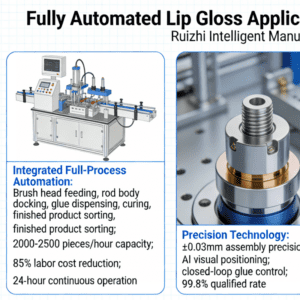

This machine integrates all core processes of lip gloss applicator assembly, including brush head feeding, rod body docking, glue dispensing, curing, and finished product sorting. It eliminates manual transfer between single processes and realizes one-stop automated production. Adopting a multi-station continuous operation design, the equipment achieves a production capacity of 2000-2500 pieces per hour, which is 7-9 times that of manual assembly.

Only one operator is needed for overall supervision, reducing labor costs by over 85% compared to traditional manual lines. The 24-hour continuous operation capability ensures timely delivery of large orders, perfectly adapting to the fast-paced production needs of the cosmetics industry.

Ensure Stable Product Quality

Equipped with advanced PLC control system and AI visual positioning technology, the machine achieves assembly precision within ±0.03mm, effectively avoiding defects such as brush head deviation and unstable glue bonding. The automatic glue dispensing module adopts closed-loop control to accurately control the glue amount, ensuring uniform bonding strength and no overflow.

The built-in real-time quality inspection unit can quickly detect unqualified products such as loose brush heads and incomplete curing, and sort them out automatically. This pushes the qualified rate of finished products to over 99.8%, greatly reducing the loss caused by manual operation errors and protecting the brand reputation.

Adapt to Diverse Production Needs

As a professional non-standard automation manufacturer, Ruizhi Intelligent Manufacturing focuses on customized solutions for different product specifications. The machine can be flexibly adjusted for various lip gloss applicator styles, including different brush head types, rod lengths and material combinations.

The parameter memory function shortens the product changeover time to 5 minutes, efficiently responding to the small-batch and multi-style production needs of cosmetic enterprises. We provide one-stop services from demand analysis and prototype customization to on-site commissioning and after-sales maintenance, paired with a 2-year warranty and 48-hour technical support, fully solving production worries for customers.