Where cooking smoke curls, human warmth touches the heart. Currently, folk customs such as the “Pig Slaughter Feast” are growing in popularity. As an important form of rural group dining, rural banquets carry the hope of reunion and local sentiments, becoming a vivid scene of mortal life in winter. However, behind the bustle, food safety hazards of self-hosted banquets cannot be ignored – problems like traditional open-air processing, mixed use of utensils and limited sanitary conditions are prone to trigger risks such as cross-contamination and food spoilage. Guarding food safety in this mortal life, the technological empowerment of food machinery is playing a pivotal role, building a solid protective barrier for group dining.

Machinery Addresses Traditional Pain Points

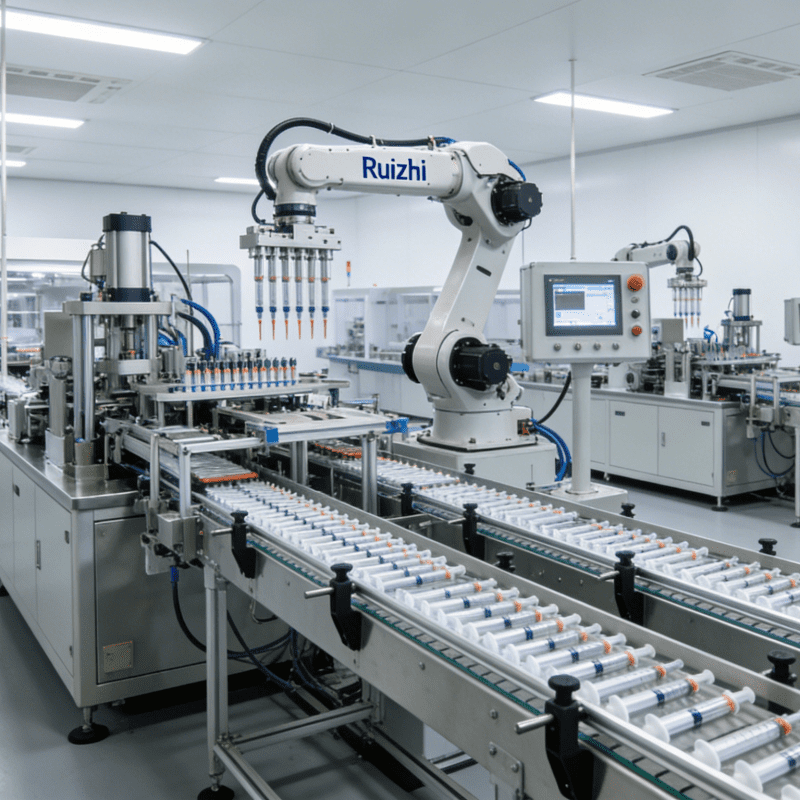

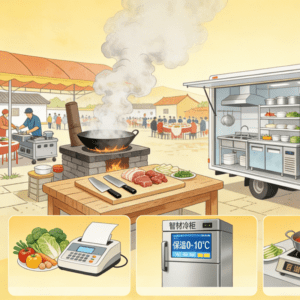

The food safety pain points of traditional rural banquets mostly stem from irregular processing links. In the past, the model of “one cutting board with three knives” and “randomly built earthen stoves and sheds” led to cross-handling of raw and cooked food, smoky cooking environments and perfunctory tableware disinfection, which became major causes of foodborne diseases. Today, the popular application of miniaturized, portable and intelligent food machinery is solving these problems from the source. The promotion of mobile smart dining trucks is a prime example. Equipped with food-grade stainless steel kitchen utensils, layered freezers and special disinfection cabinets, paired with separate cutting boards, knives and containers for raw and cooked food, these trucks eliminate cross-contamination through physical isolation. Biofuel cooking stoves bid farewell to the smoky old days, balancing environmental protection and hygiene. For meat processing, the core of the Pig Slaughter Feast, commercial meat grinders and vegetable cutters, with their food-grade stainless steel bodies and closed processing design, can not only process large quantities of ingredients efficiently but also avoid contamination in manual operations. Their features of minimal residue and easy cleaning also adapt to the high-frequency processing needs of banquets.

Machinery Standardizes Safety Processes

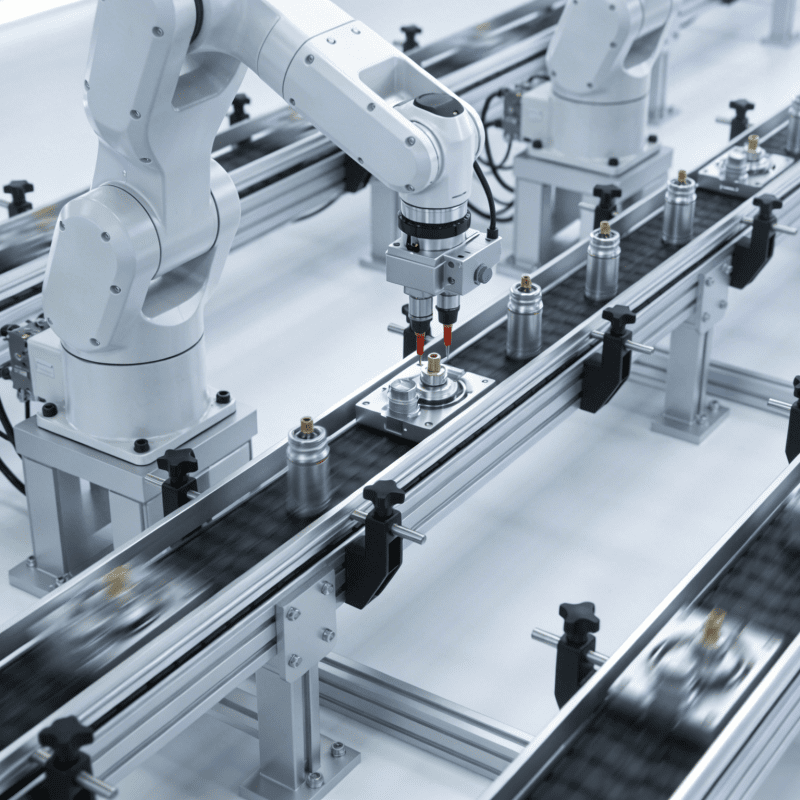

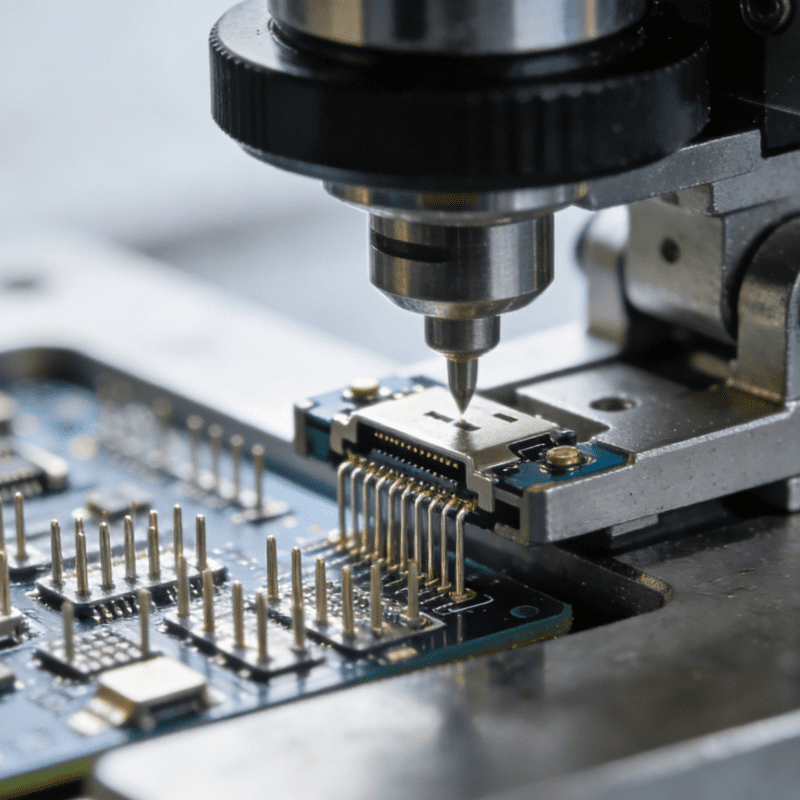

From ingredient control to process guarantee, food machinery builds a full-chain food safety protection network. At the ingredient access stage, portable pesticide residue detectors and rapid microbial detectors can complete on-site safety screening of fruits, vegetables and meat, determine bacterial colony levels within hours, and keep problematic ingredients away from the dinner table. In the storage and fresh-keeping link, intelligent freezers accurately maintain a temperature of 0-10℃ through constant temperature control systems, and combined with IoT temperature control tags, they monitor the storage status of ingredients in real time, effectively inhibiting microbial growth and providing protection for banquet sample retention and standby ingredient storage. During processing and cooking, automatic temperature-controlled cooking utensils ensure that the core temperature of large pieces of food such as meat reaches above 70℃, meeting the safety requirement of thorough cooking. In the cleaning and disinfection stage, automatic disinfection cabinets and ultraviolet sterilization equipment replace traditional boiling disinfection, killing pathogenic bacteria on tableware efficiently, and paired with clean storage cabinets, they avoid secondary contamination. The application of these machines has transformed rural banquet processing from “relying on experience” to “abiding by standards”, greatly reducing the risks caused by human operation errors.

Machinery Drives Banquet Standardization

The empowerment of food machinery has further promoted the standardized and intelligent transformation of rural banquets. Today, the model of “mobile smart dining trucks + fixed banquet venues” has been promoted in many places. The intelligent sample retention equipment and water purifiers on the dining trucks are linked with supervision platforms, forming a closed loop of “equipment guarantee + data supervision”. Supervision departments can grasp the preparation of banquets in real time through the platform, and data such as ingredient processing, cooking temperature and disinfection records are traceable, making food safety “visible and tangible”. At the same time, the popularization of small food machinery has lowered the threshold for standardized banqueting. Rural chefs can achieve standardized processing through simple operations, and village collectives can meet the dining needs of villagers without investing heavily in venue renovation. This “technology + model” innovation not only preserves the local atmosphere of rural banquets but also injects modern safety concepts.

The safety upgrade of rural banquets highlights the practical value of food machinery in people’s livelihood scenarios. From traditional folk customs to modern group dining, food safety has always been a bottom-line requirement, and the iterative upgrade of food machinery is achieving both safety and the warmth of mortal life. In the future, with the research and development of more targeted portable equipment and the integration of intelligent supervision technologies, food machinery will further sink into rural scenarios and help popularize the concept of standardized banqueting. Let technological empowerment run through the entire links of ingredient processing, production and storage, hold the bottom line of food safety for group dining, and make every reunion banquet a safe and enjoyable experience.