As a leader in non-standard automation solutions, Ruizhi Intelligent Manufacturing is committed to empowering the cosmetic industry with customized equipment. Our Custom Non-Standard Lipstick Assembly Machine is tailored to solve the pain points of traditional production—such as low efficiency, high defect rates, and poor compatibility with diverse lipstick specifications—providing a one-stop intelligent assembly solution for cosmetic manufacturers.

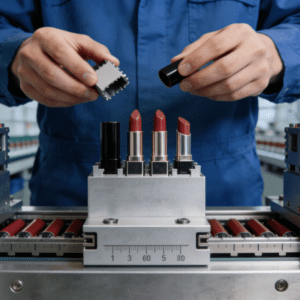

Customized Design for Diverse Lipstick Production Needs

The cosmetic industry features frequent product upgrades and diverse packaging designs, which puts high demands on assembly equipment flexibility. Ruizhi’s non-standard lipstick assembly machine breaks the limitations of standard equipment, supporting customization for various lipstick types (bullet-shaped, liquid, matte) and tube materials (aluminum, plastic, glass). Equipped with a quick-change modular design, it enables specification switching in just 5-10 minutes, adapting to small-batch and multi-variety production needs . We also customize feeding, assembly, and capping modules according to clients’ production processes, perfectly matching different tube diameters (8-15mm) and assembly workflows.

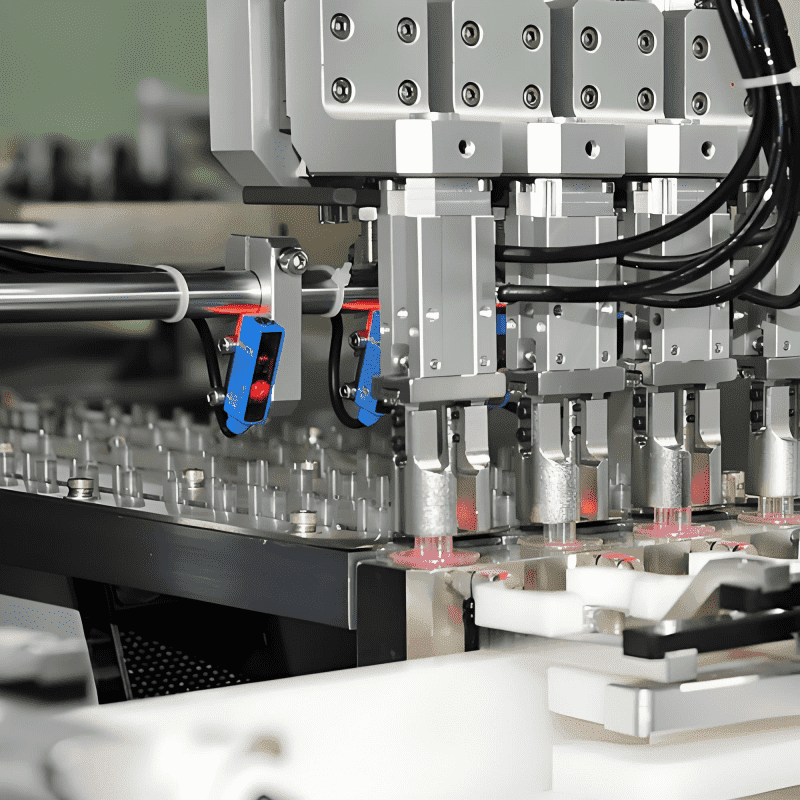

Intelligent Technology Empowers High Precision & Efficiency

Integrating advanced automation technologies, our machine realizes full-process intelligence from automatic feeding to finished product sorting. Adopting PLC control system and high-precision servo drive, it achieves an assembly accuracy of ±0.02mm and a production capacity of 60-80 pieces per minute . The built-in AI visual inspection module conducts real-time defect detection on tube alignment and assembly tightness, reducing the defect rate to below 0.5%. This intelligent solution eliminates manual intervention, cutting labor costs by 80% while ensuring stable production quality, which is crucial for cosmetic brands pursuing consistency .

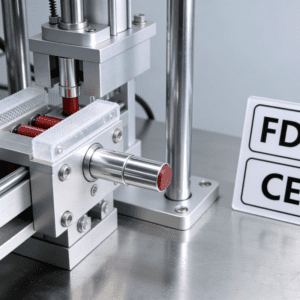

Compliance & Comprehensive Service Guarantee Production Safety

Adhering to strict cosmetic industry standards, our Custom Non-Standard Lipstick Assembly Machine uses 304 stainless steel core components, complying with FDA and CE certifications . The machine is designed with a sterile and easy-to-clean structure, avoiding cross-contamination and meeting the hygiene requirements of cosmetic production. Ruizhi provides one-stop services from scheme design and equipment customization to on-site installation, debugging, and after-sales maintenance. Our professional team tailors solutions based on clients’ workshop layout and production goals, ensuring the equipment perfectly fits into existing production lines.

Ruizhi Intelligent Manufacturing’s Custom Non-Standard Lipstick Assembly Machine combines flexibility, precision, and compliance, helping cosmetic enterprises accelerate digital transformation and gain competitive advantages in the market.