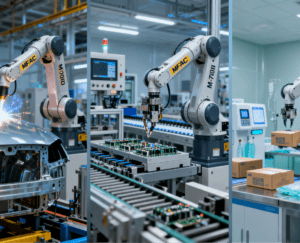

The new M-710iD/50M and M-710iD/70 six-axis multi-functional robots inherit the traditional advantages of the M-710iC series in terms of precision, efficiency, versatility, and ease of use, and inject excellent performance into application scenarios with a number of key upgrades.

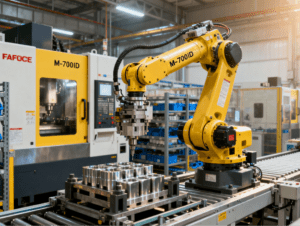

The popular six-axis multi-functional M-710 series has undergone a comprehensive upgrade! FANUC has newly launched the M-710iD/50M and M-710iD/70 robots, setting new benchmarks for applications such as machine tool loading/unloading, material handling, assembly, palletizing, and welding. Their high precision and flexible operation characteristics are particularly prominent in precision scenarios such as the Mesin Aplikator Film Otomatis Pemosisian Visi Robot — with accurate visual positioning and repeat positioning accuracy of ±0.03mm, they can achieve automatic and precise of films on complex workpiece surfaces, significantly improving the film application efficiency and consistency in fields such as electronics and automotive interiors.

The new M-710iD/50M and M-710iD/70 six-axis multi-functional robots inherit the traditional advantages of the M-710iC series in terms of precision, efficiency, versatility, and ease of use, and inject excellent performance into application scenarios with a number of key upgrades.

The M-710iD/50M has a reach radius of 2606mm and a repeat positioning accuracy of ±0.06mm. Compared with the previous generation M-710iC/45M, the maximum load has been increased by 5kg to 50kg. The innovative arc-shaped J2 axis design minimizes interference with workpieces or fixtures when the robot arm operates deep inside the box, ensuring a smoother and safer movement posture.

M-710iD/50M Robot

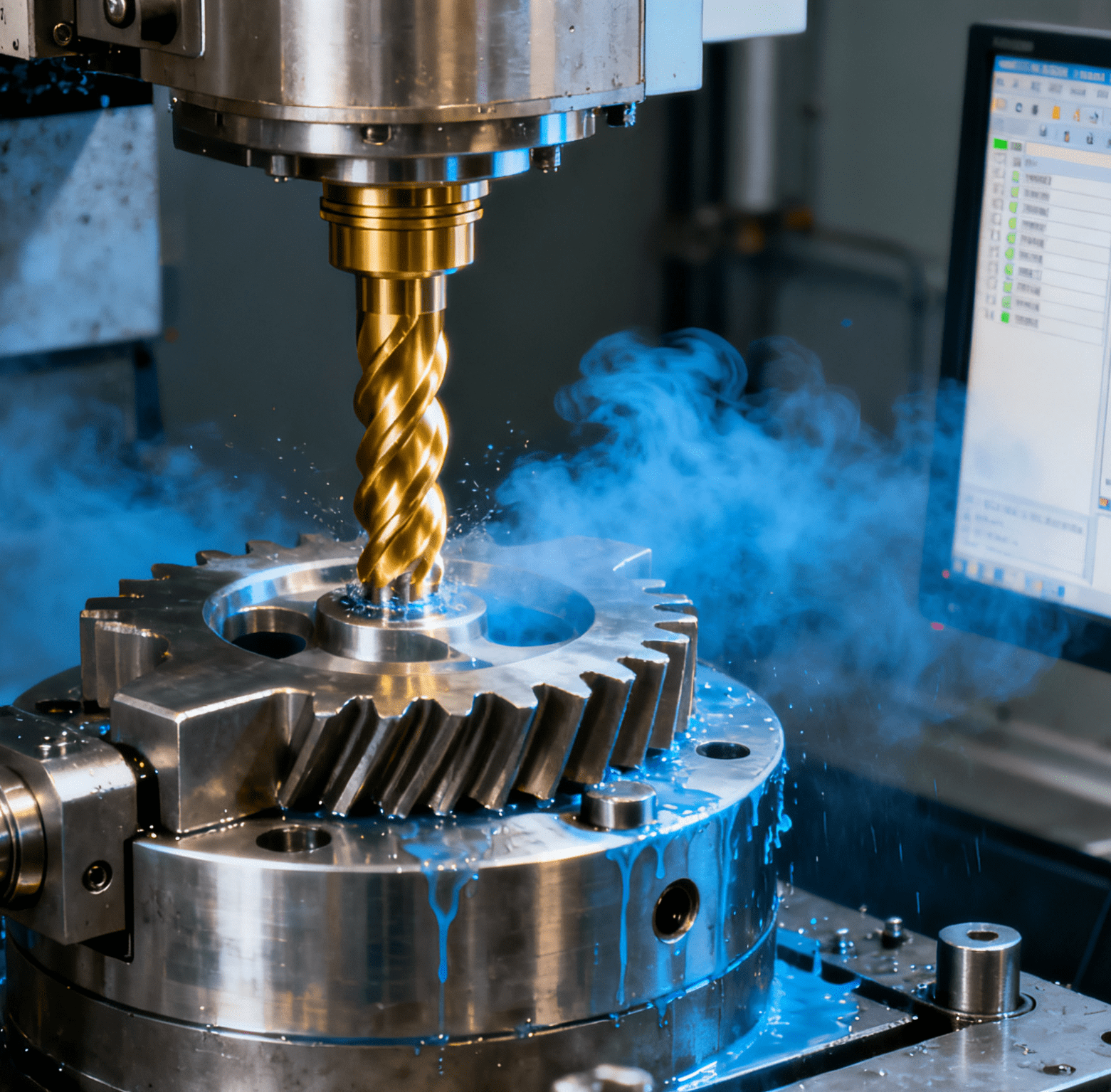

The new M-710iD series adopts a fully enclosed shield structure, achieving dust and drip resistance equivalent to IP67. It can be safely used even in harsh environments such as machine tool loading/unloading, deburring, and taking out die castings. At the same time, the maintenance-friendly robotic arm design fully integrates I/O signals and air supply interfaces.

The simultaneously launched M-710iD/70 combines the high-speed operation characteristics of the 50kg model with the load capacity of the 70kg model. The M-710iD/70 has a reach radius of 2104mm and a repeat positioning accuracy of ±0.03mm.

M-710iD/70 Robot

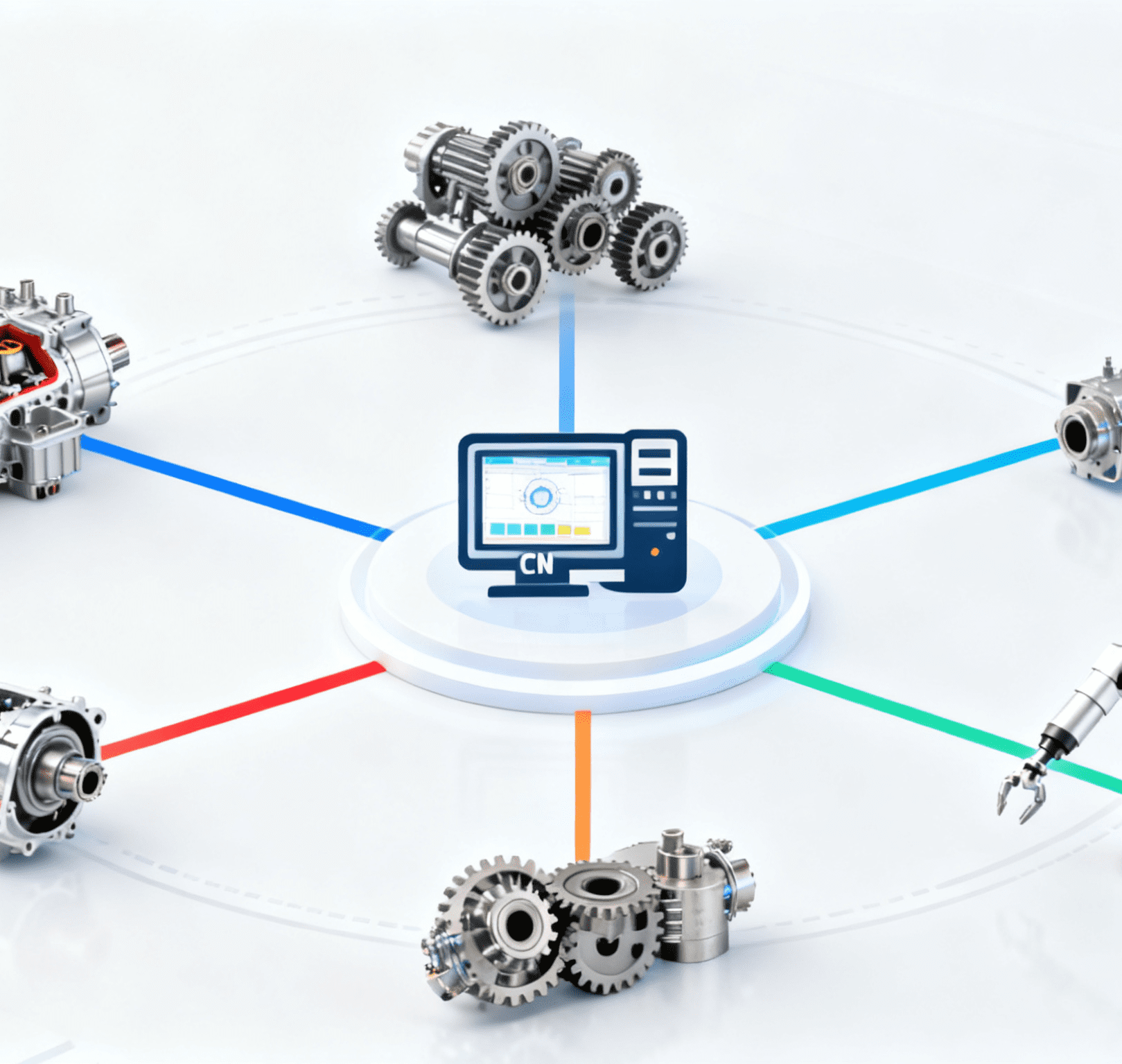

It is worth mentioning that the entire M-710iD series can be switched to a five-axis palletizing robot after selecting the palletizing mode without installing additional hardware. In addition, the new series supports multiple installation methods such as floor-mounted, wall-mounted, and ceiling-mounted, greatly improving application flexibility.

The new M-710iD series can be widely used in industries such as automotive, electronics, pharmaceuticals, food and medical, machining, casting, and injection molding, and can easily cope with various working conditions in production, injecting new driving force into the industry.