Assembly, at its core, refers to the professional process of integrating individual parts or sub-assemblies into finished products or higher-level components. In industrial settings, this process is typically carried out on optimized assembly lines to maximize time efficiency and cost savings. As a broad-ranging term, “assembly” encompasses diverse steps across industries—from simple part joining to complex system integration—and adapts to both small-batch and high-volume production, depending on the complexity of the modules being assembled. Its role in the production workflow is highly flexible: it can serve as an early intermediate step (e.g., building a sub-assembly like a car door module) or the final step in creating a complete end product (e.g., assembling a fully functional washing machine). To ensure precision, industrial assembly often relies on the expertise of specialized assembly technicians, especially for high-precision or custom components.

The Technical Foundation of Assembly

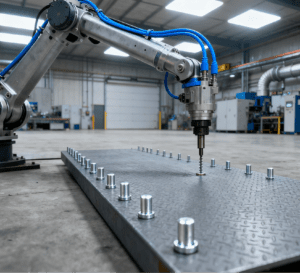

Assembly is a critical link in the product value chain, as it transforms discrete parts (mechanical, hydraulic, pneumatic, electrical, or a combination thereof) into high-performance integrated systems. The choice of assembly method depends on the technical design of the product, and these methods are implemented in three main modes—manual, semi-automated, or fully automated—on optimized assembly lines. Among the key supporting technologies for fully automated assembly workflows, the 4 – Axis Robotic Injection Molding Part Removal System plays a pivotal bridging role between injection molding and subsequent assembly processes. Specifically engineered for extracting injection-molded parts (such as automotive interior trim components, electronic device casings, or small medical plastic fittings) from molds, its 4-axis movement (integrating X, Y, Z linear motion and rotational motion around the Z-axis) enables flexible access to narrow or complex mold cavities, ensuring rapid, damage-free part removal. Equipped with vision sensing and precision positioning, it can directly transfer the extracted parts to the next assembly station (e.g., aligning plastic housings for bonding or riveting) without manual handling, eliminating efficiency bottlenecks and surface scratches caused by human transfer, which is particularly critical for high-volume production in automotive, consumer electronics, and medical device industries. Below are the core assembly technologies most widely used in sub-assembly and final assembly processes:

Welding: Permanent Bonding via Thermal InputWelding creates a permanent connection between two components by applying localized thermal energy (e.g., laser, arc, or ultrasonic heat). During the process, the contact surfaces of the parts are melted, and upon cooling, the molten materials fuse to form a strong, seamless bond.Key advantage: Delivers high structural strength, making it ideal for load-bearing components.Typical applications: Metal components in automotive (e.g., chassis frame joining), aerospace (e.g., aircraft fuselage sections), and heavy machinery industries.Common heat sources: Laser welding (for high-precision, low-heat-input scenarios like electronic component leads) and arc welding (for large-scale metal structures).

Riveting: Mechanical Joining via Plastic DeformationRiveting is a force-fitted joining process that relies on the plastic deformation of a rivet. After inserting the rivet into pre-drilled holes in the components to be connected, external force is applied to deform the rivet’s end (e.g., flattening or expanding it), creating a tight, non-detachable joint.Classification:

Solid riveting: Uses solid metal rivets, suitable for high-strength applications like aircraft wing structures.

Blind riveting: Uses hollow rivets, ideal for scenarios where only one side of the component is accessible (e.g., automotive interior panels).

Punch riveting: Employs high-speed punches to deform rivets, common in thin-sheet metal joining (e.g., appliance casings).

Key advantage: No thermal damage to components, making it suitable for heat-sensitive materials (e.g., thin aluminum sheets).

Bonding: Non-Mechanical Joining with Adhesives

Bonding uses adhesives (epoxy, acrylic, or silicone-based) to create a permanent connection between two components, without relying on mechanical fasteners (e.g., screws, rivets).

Key advantages:

Versatility: Works with almost all materials, including metals, plastics, composites, and even dissimilar materials (e.g., aluminum and plastic).

Uniform stress distribution: Adhesives spread stress across the entire bonded area, avoiding stress concentration (a common issue with rivets or screws).

Aesthetic and structural benefits: Creates seamless joints (no visible fasteners) and avoids thermal or mechanical damage to fragile parts (e.g., electronic circuit boards).

Typical applications: Electronic device casings (e.g., smartphone back covers), medical devices (e.g., plastic catheter components), and automotive interior trim.

Alignment: Precision Positioning for High-Accuracy AssemblyAlignment is a preliminary manufacturing step in sub-assembly, focused on the ultra-precise positioning of components before joining. It ensures that parts are aligned to strict dimensional tolerances (often within ±0.01mm) to avoid assembly errors or performance issues.Key requirement: Relies on advanced positioning tools, such as laser alignment systems, optical comparators, or CNC-guided fixtures.Critical applications: High-precision industries like aerospace (e.g., aligning turbine blades in an engine) and semiconductors (e.g., positioning microchips on PCBs).

Inspection: Quality Assurance for Final ComplianceInspection is typically the final step in assembly, serving as a quality control measure to ensure the finished assembly (or sub-assembly) meets predefined quality standards and tolerances.Inspection content: Dimensional accuracy (e.g., checking part spacing with a coordinate measuring machine), joint strength (e.g., testing rivet pull-out force), and functional performance (e.g., verifying a welded pipe’s leak tightness).Common methods: Automated vision inspection (for fast, repeatable checks), pressure testing (for sealed components), and torque testing (for fastener tightness).Purpose: Prevents defective products from entering the next workflow or reaching end-users, reducing rework costs and safety risks.

Materials Suitable for Industrial Assembly

Industrial assembly has no inherent material limitations—virtually all industry-common materials can be joined and assembled into components or end products. The choice of material depends on the product’s function, environment, and performance requirements, and is often paired with a complementary assembly technology.

Metals are among the most widely used materials, with common examples including steel, aluminum, and titanium alloy. They are typically paired with welding, riveting, or bolt fastening technologies, as these methods leverage metals’ structural strength—such pairings are common in automotive chassis and aerospace parts, where load-bearing capacity is critical.

Plastics like ABS, PC, and nylon are another key category, often assembled via bonding, ultrasonic welding, or snap-fit. These technologies avoid damaging plastics’ relatively low heat resistance and structural rigidity, making them ideal for electronic device casings (e.g., smartphone back covers) and toy parts.

Wood, including plywood and solid wood, is commonly assembled using screwing or wood-specific glues. This combination balances ease of processing and structural stability, and is widely used in furniture manufacturing and packaging box production.

Composites, such as carbon fiber-reinforced plastic (CFRP), are suited to bonding or laser welding. These technologies preserve the composites’ high strength-to-weight ratio, making them a top choice for high-performance parts like racing car bodies and aircraft interiors.

Conclusion

Industrial assembly is a dynamic, adaptable process that bridges individual parts to finished products, with its methods and materials tailored to industry-specific needs. Whether through welding for strong metal joints, bonding for seamless plastic components, or precision alignment for aerospace parts, the right assembly technology ensures products meet performance, cost, and quality goals. As manufacturing trends like customization and miniaturization advance, assembly processes will continue to evolve—integrating more automation and smart inspection tools—to keep pace with growing industry demands.