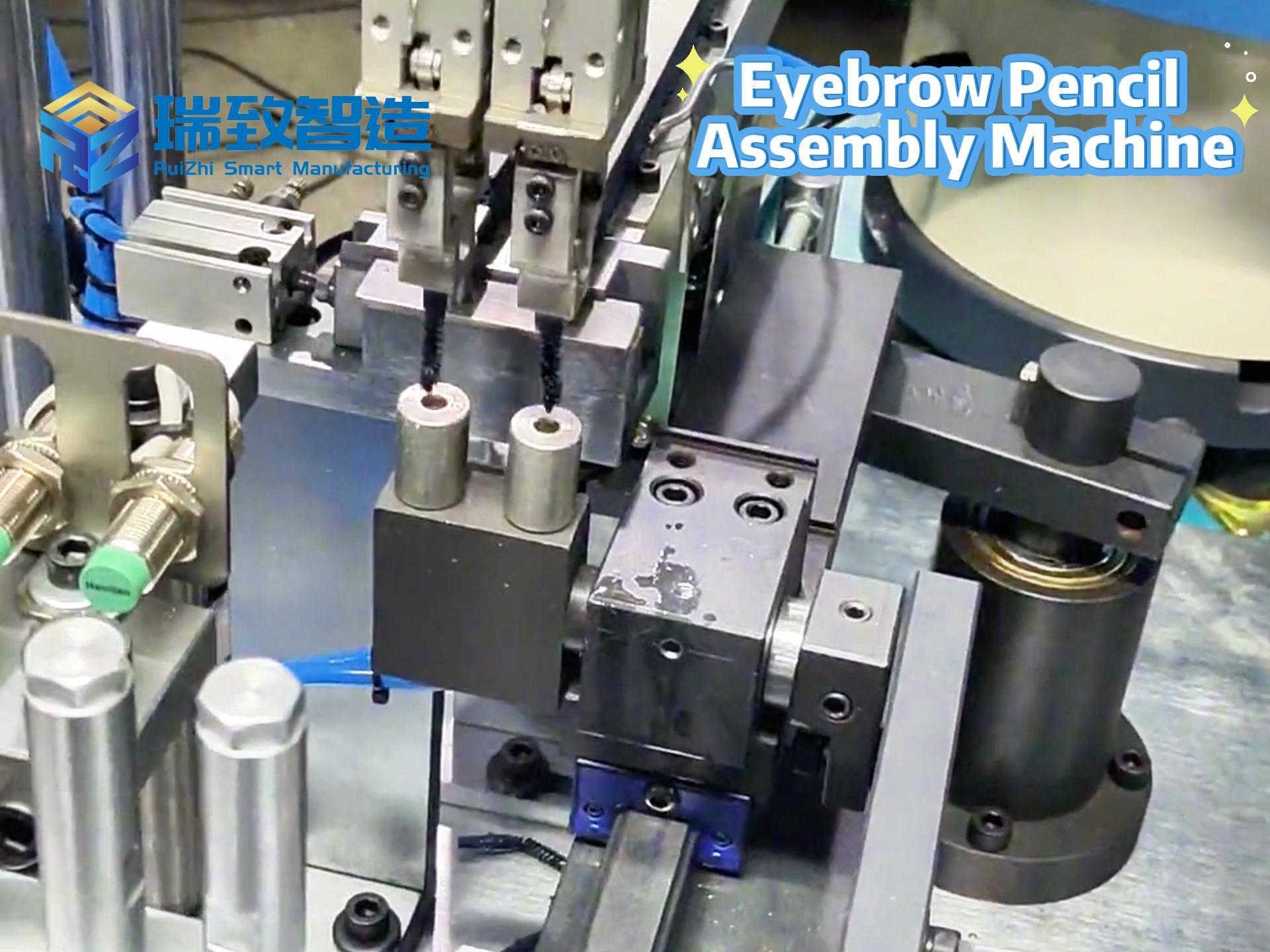

With the rapid development of new energy vehicles, the demand for automotive electrical contactors—core components ensuring safe power transmission in vehicle circuits—has surged. However, the assembly of automotive electrical contactors faces unique challenges, such as strict requirements for high-voltage resistance, miniaturization, and multi-model compatibility, which traditional standard assembly equipment can hardly meet. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, customizes high-precision, efficient assembly systems for automotive electrical contactor production, helping manufacturers break through production bottlenecks.

Core Advantages of Ruizhi’s Non-Standard Automation Solutions for Automotive Electrical Contactor Assembly

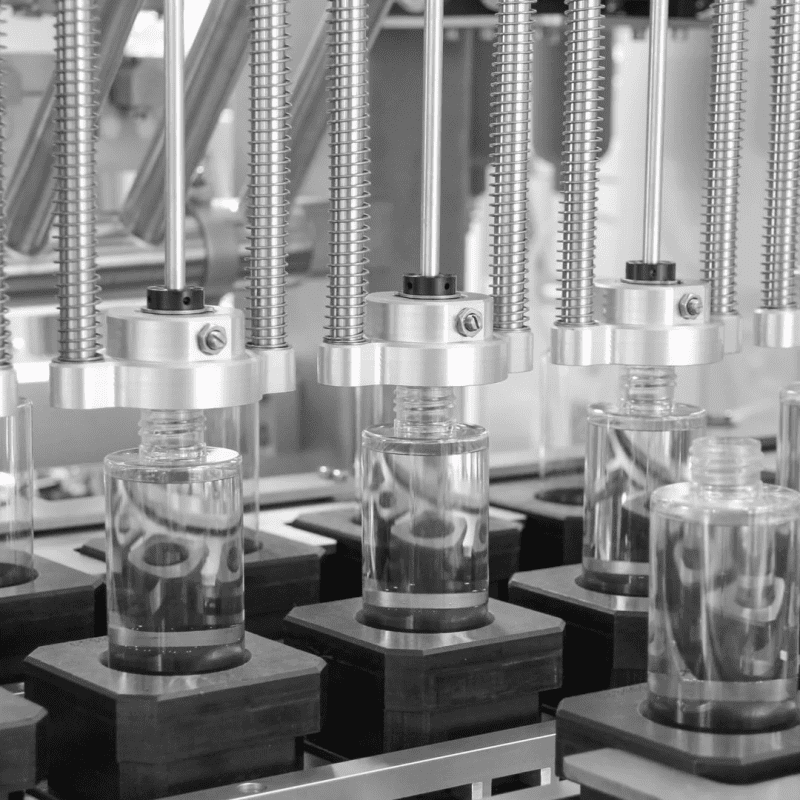

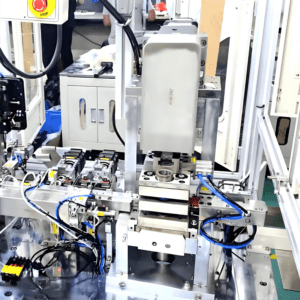

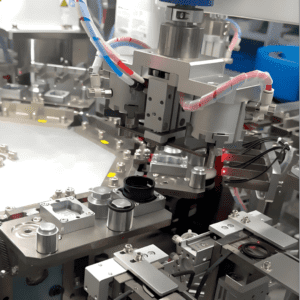

The core advantages of Ruizhi’s non-standard automation solutions for automotive electrical contactor assembly are reflected in three aspects. Firstly, customized modular design adapts to diverse product specifications. Whether it is high-voltage contactors for 400V/800V power systems or miniaturized contactors for smart vehicles, the system can realize quick model switching within 8 minutes, reducing downtime caused by equipment adjustment by over 70%. Secondly, integrated intelligent quality control ensures assembly precision. Equipped with advanced machine vision systems and real-time torque monitoring technology, the assembly line can automatically detect contact gap, terminal crimping quality, and component installation accuracy, controlling the defect rate to less than 0.02% and meeting the strict safety standards of automotive electrical components. Thirdly, seamless integration with existing production lines maximizes resource utilization. The solution is designed according to the customer’s on-site layout and production process, supporting flexible connection with upstream and downstream processes such as material feeding and finished product testing, and improving the overall production efficiency of the workshop.

Case Study: Customized Assembly Line Transforms EV Contactor Production

A typical case is a leading new energy vehicle component manufacturer in Jiangsu, which specializes in producing high-voltage contactors for electric vehicles. The customer was plagued by three major problems: frequent model changes led to long equipment adjustment time (over 30 minutes per change), manual assembly resulted in low efficiency (only 350 units per hour), and unstable product quality (defect rate of 1.2%) due to difficulty in controlling contact pressure. After in-depth communication and on-site investigation, Ruizhi Intelligent Manufacturing customized a fully automatic non-standard automotive electrical contactor assembly line for the customer. The line adopted a modular structure to adapt to 6 types of contactor products, integrated precision pressure sensors to ensure stable contact pressure, and configured an intelligent sorting system to automatically separate unqualified products.

After the implementation of the assembly line, the customer achieved remarkable results: the model switching time was shortened to 6 minutes, the production efficiency was increased to 1200 units per hour (an increase of 243%), the defect rate was reduced to 0.015%, and the labor cost was saved by 50% annually. The stable operation of the assembly line also helped the customer pass the quality audit of international automobile manufacturers smoothly, expanding the overseas market share.

Ruizhi Intelligent Manufacturing: Your Trusted Partner for Automotive Electrical Automation

At Ruizhi Intelligent Manufacturing, we have rich experience in the field of automotive electrical component assembly automation. Our professional team provides one-stop services from demand analysis, program design, equipment manufacturing to on-site commissioning, ensuring that each non-standard solution accurately matches the customer’s production needs. We closely follow the development trend of the automotive industry, continuously integrate advanced technologies such as IoT and digital twins into assembly systems, and help customers achieve intelligent upgrading of production.

If you are facing challenges in automotive electrical contactor assembly such as low efficiency, poor quality stability, or difficulty in adapting to multi-model production, Ruizhi Intelligent Manufacturing is your reliable partner. Contact us today to get a customized non-standard automation solution and empower your high-quality production of automotive electrical contactors.