As manufacturing industries such as automotive, new energy, and home appliances pursue intelligent upgrading, frame pick-up and handling—an essential link in production lines—face growing demands for efficiency, precision, and safety. Traditional manual handling or standard robotic systems struggle to adapt to scenarios like heavy frame loads, multi-model switching, and high-precision positioning. Ruizhi Intelligent Manufacturing’s non-standard 4-axis robotic frame pick-up automation solutions address these pain points, providing customized, efficient, and reliable handling support for manufacturers.

Key Pain Points in Frame Pick-up: Why 4-Axis Robotic Automation Is Indispensable

Frame pick-up in modern manufacturing encounters three core challenges. Firstly, low efficiency and high safety risks: Heavy frames (50-500kg) rely on manual or simple hoist handling, leading to low efficiency (20-30 units/hour) and potential safety hazards like collisions or worker injuries. Secondly, poor positioning precision: Frames for automotive bodies, battery packs, or equipment shells require sub-millimeter positioning accuracy for subsequent assembly, which manual operation or standard robots cannot stably achieve. Thirdly, inflexible multi-model adaptation: Manufacturers often produce multiple frame specifications, and standard equipment requires long retooling time (30-60 minutes), causing production line downtime. These issues make 4-axis robotic automation with non-standard customization a critical upgrade direction.

Core Advantages of Ruizhi’s Non-Standard 4-Axis Robotic Automation Solutions

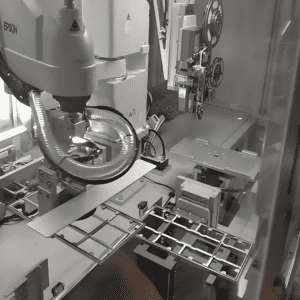

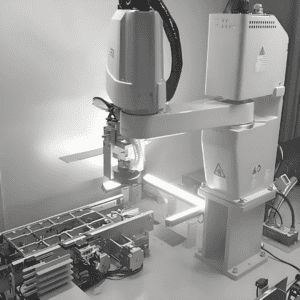

Ruizhi Intelligent Manufacturing’s 4-axis robotic frame pick-up automation stands out with three tailored advantages. First, high-precision and stable positioning: Equipped with high-resolution vision systems and servo control technology, the 4-axis robot achieves ±0.01mm repeat positioning accuracy, ensuring precise alignment with assembly stations. Second, flexible multi-model adaptation: Adopting a modular design, the system supports quick switching between 6-10 frame models within 8 minutes, reducing retooling downtime by over 80% compared to standard equipment. Third, safe and efficient handling: The 4-axis structure balances load capacity (up to 800kg) and operational flexibility, paired with anti-collision sensors and safety interlocks to eliminate handling risks; production efficiency reaches 150-200 units/hour, 5-8 times higher than manual handling. Additionally, the solution can be seamlessly integrated with existing production lines, maximizing resource utilization.

4-Axis Automation Transforms Automotive Frame Handling

A leading automotive body frame manufacturer in Shandong faced critical challenges: Manual handling of 300kg steel frames led to low efficiency (25 units/hour) and high labor costs; positioning errors often caused assembly delays, with a defect rate of 1.8%; switching between 4 frame models required 45 minutes of retooling, severely affecting production schedules. After in-depth on-site analysis, Ruizhi Intelligent Manufacturing customized a non-standard 4-axis robotic frame pick-up system for the client.

The solution featured a 500kg load 4-axis robot, integrated 3D vision positioning, and quick-change fixtures. It automatically identified frame models, adjusted clamping force, and achieved precise placement. Post-implementation, the client’s handling efficiency surged to 180 units/hour (a 620% increase), positioning accuracy improved to ±0.008mm, and the defect rate dropped to 0.01%. Model changeover time was shortened to 6 minutes, and annual labor costs were reduced by 65%. The stable operation of the system also helped the client pass the smart factory certification of international automakers.

Ruizhi Intelligent Manufacturing boasts rich experience in 4-axis robotic automation, with a professional team providing one-stop services from demand analysis, scheme design, and equipment manufacturing to on-site commissioning. We closely track industry trends, integrating IoT and digital twin technologies to realize real-time monitoring and predictive maintenance of robotic systems.

If you’re troubled by low efficiency, poor precision, or inflexible adaptation in frame pick-up, contact Ruizhi Intelligent Manufacturing today. Let our non-standard 4-axis robotic frame pick-up automation solutions empower your production line with intelligence and efficiency.