In today’s manufacturing sector, CNC (Computer Numerical Control) equipment plays a core pillar role. However, many business owners are troubled by the persistently high post-sales maintenance costs of such equipment. What exactly are the reasons behind this phenomenon?

Hardware-Level Pressure: Exclusive Components and Irreversible Accidental Damage

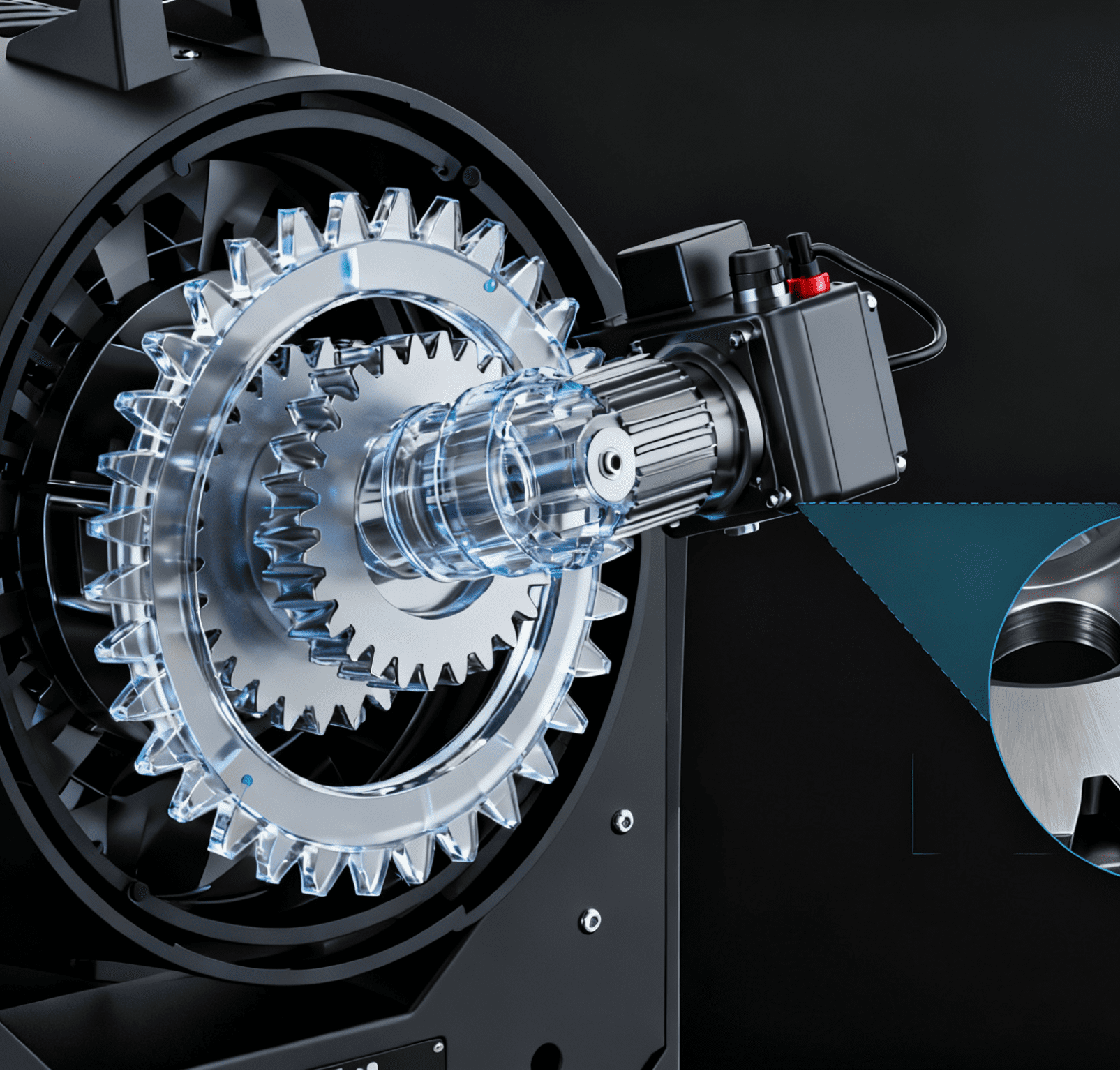

The uniqueness of equipment components is one of the key factors. CNC equipment, especially CNC machine tools used for precision machining, has an extremely complex internal structure, and its components are often high-precision and customized. Through long-term practice, Aier Precision Machinery has found that once a critical component (such as a high-precision lead screw or guide rail) malfunctions, it can basically only be supplied by the original manufacturer due to poor market universality. These exclusive components are expensive, and additional high costs—such as transportation fees and import taxes (for imported equipment)—greatly drive up maintenance expenses. Moreover, the cycle from placing a purchase order to the arrival and installation of the component is long, leading to extended equipment downtime; the resulting indirect losses are also not to be underestimated.

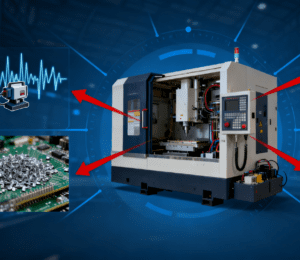

Additionally, the risk of accidental damage also drives up costs. The operating environment of CNC equipment is complex; factors such as electromagnetic interference, dust pollution, and voltage fluctuations in the machining workshop can cause irreversible damage to sensitive electronic components and precision mechanical structures in an instant. Although protective measures can be taken, sudden accidents cannot be completely prevented. Once they occur, expensive repair and replacement costs follow.

Technology & Manpower Bottlenecks: Scarce Professionals and Software Adaptation Challenges

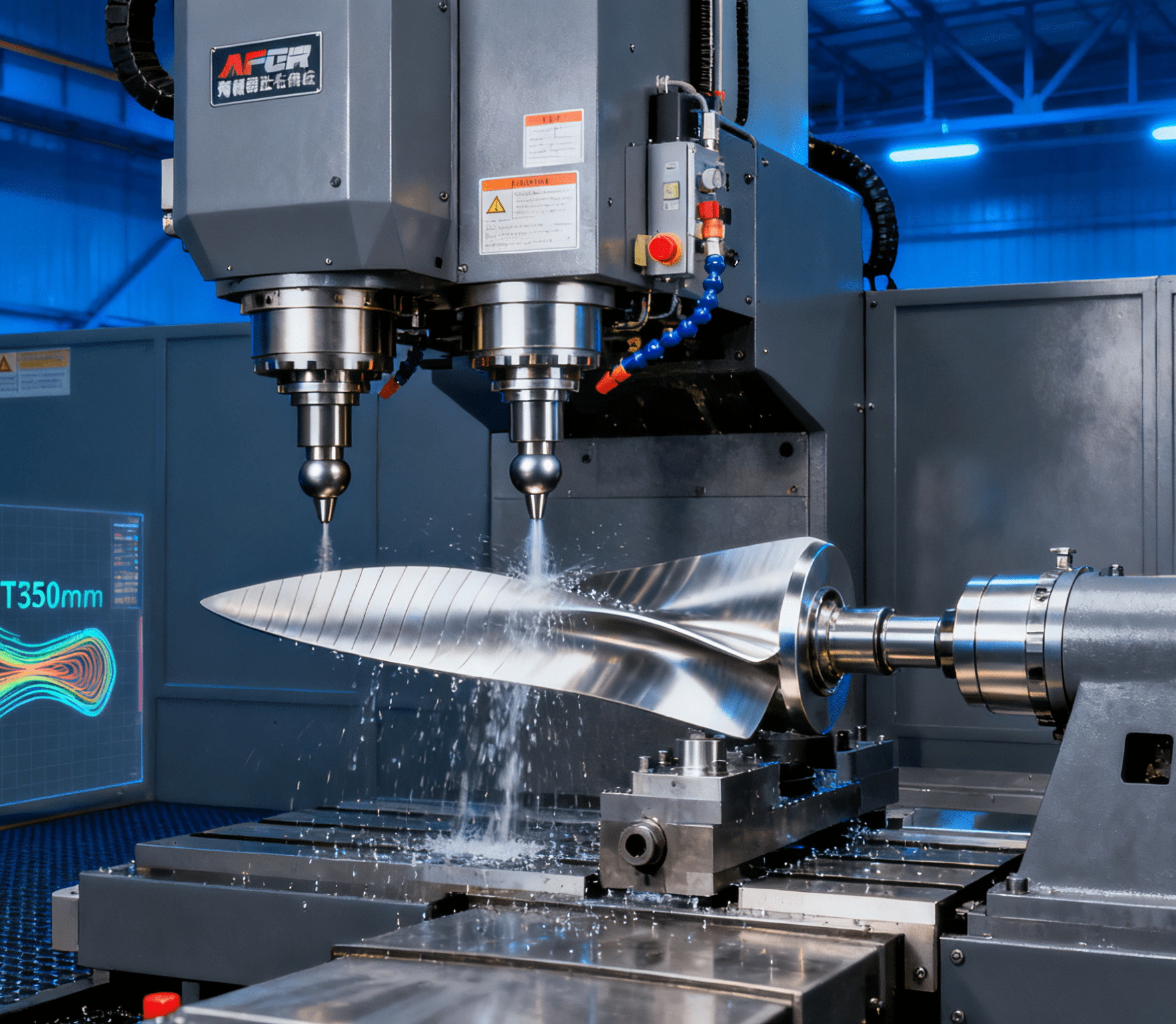

The shortage of professional technicians further pushes up maintenance costs. CNC precision machining relies on CNC equipment that integrates cutting-edge technologies across multiple fields, including machinery, electronics, and software. This requires maintenance personnel to possess a comprehensive knowledge system. Aier Precision Machinery is well aware that cultivating a mature CNC maintenance technician not only requires investing significant time in professional learning and practical experience accumulation but also necessitates continuous training to keep up with new technological updates—only then can they accurately diagnose and repair complex faults

. Consequently, when enterprises hire such professional talents, they have to pay high salaries, making labor costs account for a significant proportion of post-sales maintenance expenses.

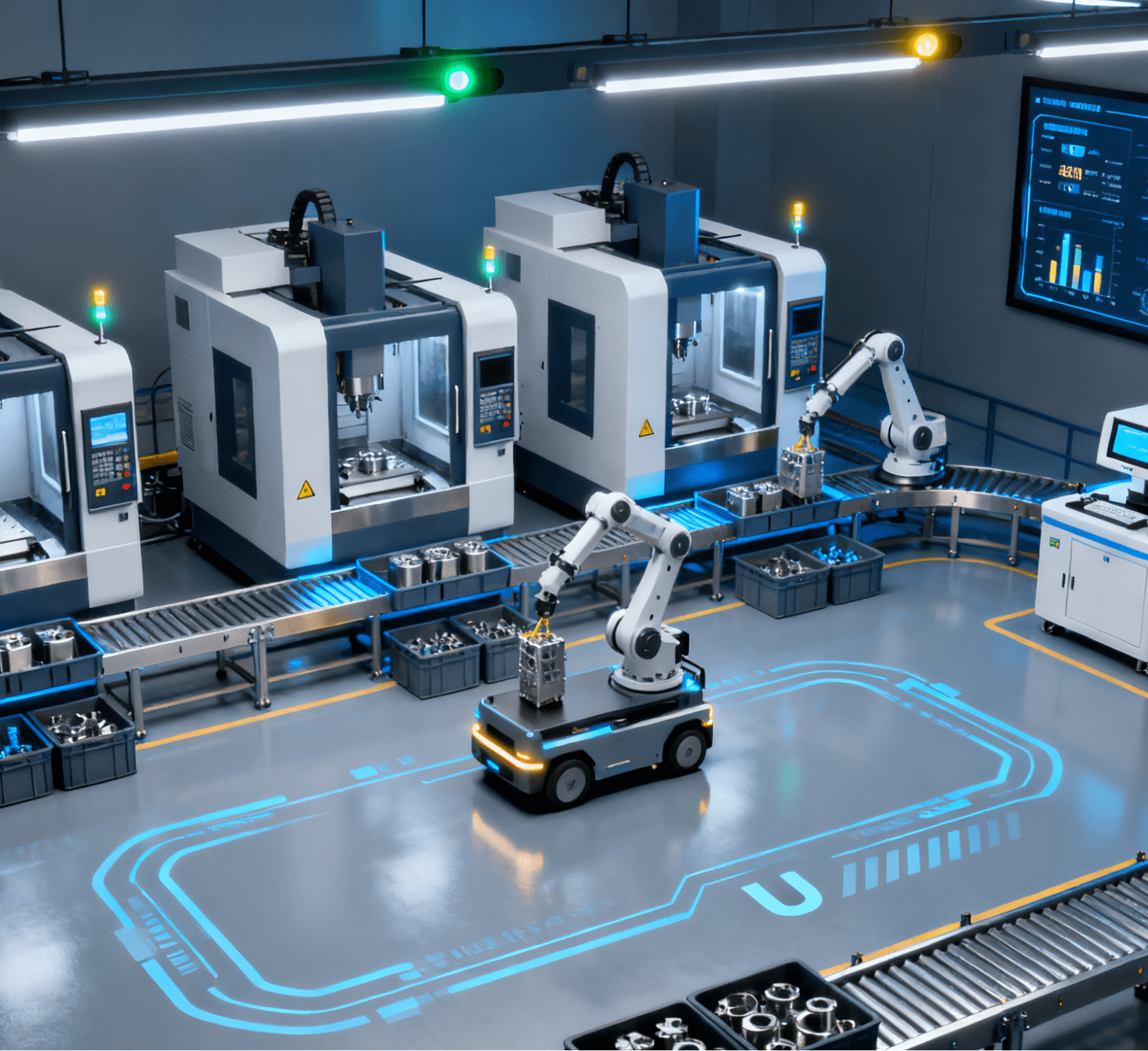

Challenges in software upgrades and adaptation also cannot be ignored. With the accelerated iteration of CNC technology, the control system software of CNC equipment needs to be continuously upgraded to optimize performance and be compatible with new functions. However, software upgrading is not a simple “one-click operation.” When assisting customers, Aier Precision Machinery has learned that, on the one hand, new software versions may have compatibility issues—conflicting with existing hardware or other external equipment—making the debugging process time-consuming and labor-intensive. On the other hand, the cost of purchasing official software upgrade licenses is exorbitant; the expense of upgrading the software of some high-end CNC systems can even match the price of a small ordinary piece of equipment. This leaves enterprises hesitant but with no alternative.

Operational Maintenance Burden: Sustained Investment in High-Standard Daily Upkeep

High requirements for daily maintenance further increase the cost burden. To ensure the precision and stability of CNC equipment in precision machining, daily maintenance procedures—such as cleaning, lubrication, and calibration—are complex and must strictly comply with standards. Aier Precision Machinery often reminds customers that using non-compliant cleaning agents or neglecting regular calibration may trigger equipment malfunctions. For this reason, enterprises either need to establish a professional maintenance team or hire external professional maintenance services—both of which undoubtedly lead to continuous increases in financial investment in post-sales maintenance.