Core Definition of the Equipment

Automated assembly equipment refers to a cluster of professional devices that integrate technologies such as mechanical transmission, precision sensing, PLC (Programmable Logic Controller), and machine vision, with the goal of “reducing manual intervention”. It enables autonomous operation of processes including part feeding, positioning and alignment, assembly connection (e.g., press-fitting, riveting, welding), quality inspection, and finished product unloading.

The key difference between automated assembly equipment and semi-automated equipment lies in its ability to handle parameter fluctuations during assembly (such as part dimension deviations and workstation switching) through pre-set programs or adaptive algorithms, without the need for real-time manual adjustments. Typically, its precision ranges from ±0.01mm to ±0.05mm, making it suitable for diverse assembly needs—from small electronic components to large automotive parts.

Full-Lifecycle Service System

To ensure that the equipment is deeply adapted to an enterprise’s production scenarios, the automated assembly service has formed an end-to-end support system covering “pre-planning, mid-term implementation, and post-optimization”. The details are as follows:

Pre-design and Customized Development: Based on the enterprise’s product characteristics (e.g., part material, assembly process requirements), services include 3D modeling via CAD (Computer-Aided Design), processing path planning via CAM (Computer-Aided Manufacturing), and even customized equipment structure design for special scenarios (e.g., cleanrooms, explosion-proof environments). For example, syringe assembly equipment in the medical industry must adopt stainless steel bodies and HEPA filtration systems to meet GMP cleanliness standards; while automotive part assembly equipment needs to adapt to the press-fitting requirements of high-strength metal parts and enhance the load capacity of the transmission system.

System Integration and Turnkey Delivery: Single equipment is connected to upstream and downstream links of the production line (e.g., upstream injection molding machines, downstream inspection equipment) via industrial buses (such as Profinet and EtherCAT) to achieve data interconnection and collaborative operation. Some service providers offer “turnkey systems”—one-stop services ranging from solution design, equipment manufacturing, on-site installation and commissioning to employee training. For instance, when building a PCB insertion line for an electronics manufacturer, not only are the insertion devices delivered, but simultaneous linkage commissioning with feeding machines and reflow soldering equipment is also completed, ensuring the production line can start operation immediately after deployment.

Post-operation Maintenance and Upgrade Support: This includes on-site fault diagnosis, regular maintenance (e.g., sensor calibration, lubrication of transmission components, software version updates). Some enterprises also provide remote maintenance services: real-time operation data (such as motor temperature, press-fitting pressure curves) is collected via IoT modules installed on the equipment to predict potential faults (e.g., abnormal vibration caused by bearing wear), thereby reducing unplanned downtime. In response to enterprises’ new product iteration needs, equipment modification services are also available—such as adjusting the stroke of robotic arms or upgrading machine vision recognition algorithms to adapt to the assembly of new-specification parts.

Process Optimization and Prototype Testing: To meet enterprises’ new product R&D needs, in-house prototype testing services are provided to verify process feasibility through small-batch assembly. For example, in the R&D of tab assembly equipment for new energy vehicle batteries, a prototype machine is first used to test the impact of different press-fitting forces and temperatures on tab connection strength. After determining the optimal parameters, mass deployment is carried out to avoid issues such as tab deformation and cold soldering during mass production.

Core Technology Types and Application Scenarios of Automated Assembly Equipment

The technical selection of automated assembly equipment must align with part characteristics, assembly processes, and production scale. Different technology types correspond to differentiated application needs, which can be categorized as follows:

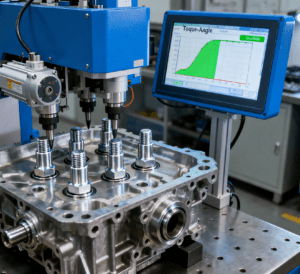

Assembly PressesTheir core principle is to use hydraulic, pneumatic, or servo-driven systems to generate controllable pressure, enabling precise press-fitting of parts (e.g., interference fit between bushings and housings, assembly of bearings and rotating shafts). They are mainly used in scenarios such as bearing assembly for automotive gearboxes, press-fitting of motor end caps, and installation of hydraulic valve cores.The advantages of this technology include real-time monitoring of pressure and displacement (some equipment is equipped with force-displacement curve analysis functions), which effectively prevents part damage due to over-pressurization. The press-fitting precision can reach ±0.005mm, and data from each press-fitting operation can be automatically recorded to meet quality traceability requirements.

Automatic Insertion EquipmentThrough the collaborative movement of robotic arms or dedicated fixtures, electronic components (e.g., resistors, capacitors, connectors, pins) are accurately inserted into pre-drilled holes on PCBs. Some equipment also integrates component polarity identification to prevent reverse insertion.Typical applications include component insertion for consumer electronics PCBs (e.g., TV motherboards), assembly of industrial controller components, and insertion for automotive electronic modules (e.g., in-vehicle navigation motherboards). Its advantages are adaptability to multi-specification components and high insertion speed (300–500 pieces per minute)—far exceeding manual efficiency. Additionally, machine vision is used for positioning and correcting hole deviations, resulting in an insertion pass rate of over 99.8% and significantly reducing the risk of manual insertion errors.

Brazing and Welding EquipmentThese equipment use laser, ultrasonic, arc, or induction heating to melt solder or the connection parts of components, achieving permanent bonding of metal/plastic parts. They can be subdivided by application scenario:Laser welding for engine blades in the aerospace industry (small heat-affected zone, high welding strength);Arc welding for automotive body frames (suitable for high-strength steel materials);Ultrasonic welding for mobile phone middle frames in consumer electronics (no solder required, suitable for thin-walled parts);Induction welding for stainless steel pipes in medical equipment (pollution-free welding process).The core advantage of this technology is high connection reliability. Some high-end equipment is equipped with 3D vision systems to real-time correct part assembly deviations and ensure welding position precision.

Riveting and Seaming/Folding EquipmentRiveting technology is divided into impact riveting (mechanical impact deforms rivets to fix parts) and non-impact riveting (forming via rolling or spinning without impact vibration). Seaming/folding equipment uses edge-folding mechanisms and pressing components to fold and seam parts (e.g., flanging and interlocking of metal plates, snap-seaming of plastic casings).Main applications include riveting of automotive body panels (e.g., door inner panels and reinforcing ribs), folding and seaming of home appliance casings (e.g., washing machine outer tubs), and riveting assembly of hardware tools (e.g., pliers, scissors). Among these, non-impact riveting is suitable for fragile parts (e.g., electronic device casings) to avoid part cracking caused by impact; seaming/folding equipment enables continuous production and improves batch assembly efficiency.

Insert Molding Assembly (IMA) EquipmentMetal inserts (e.g., screws, nuts, bushings) are pre-fixed in injection molds, followed by plastic injection. After the plastic cools and solidifies, the metal inserts and plastic parts form an integrated structure, eliminating the need for subsequent manual assembly.Typical applications include home appliance knobs (metal shafts + plastic casings), automotive sensor housings (metal terminals + plastic shells), and electronic connectors (metal pins + plastic bases). The advantages of this technology are reduced subsequent assembly processes, high insert positioning precision (±0.02mm), lower risk of part loosening, and stronger bonding between plastic and metal—making it suitable for scenarios involving long-term stress or vibration.

Screw and Nut Tightening EquipmentDriven by servo motors, screwdrivers or nut runners tighten screws/nuts according to pre-set torque, angle, or number of turns. Some equipment also integrates torque feedback functions to automatically determine whether tightening is in place (e.g., real-time alarms for thread stripping or missing tightening).Main applications include bolt tightening for new energy vehicle battery packs (torque precision ±2%, meeting waterproof and sealing requirements), screw fixing for medical devices (e.g., surgical instruments, requiring sterile operation and disinfectable equipment surfaces), and screw assembly for home appliance panels (adapting to different screw specifications and supporting automatic bit change). Its advantages are controllable tightening processes and recordable parameters (torque, angle, time) for each screw, meeting strict traceability standards in the automotive and medical industries.

Biztosíték összeszerelő gépThis equipment integrates precision feeding (via vibration bowls for fuse tubes, metal electrodes, and insulating end caps), machine vision positioning, and in-line electrical testing to realize the full-automated assembly of fuses. Key processes include accurate insertion of electrodes into fuse tubes (guided by 2D vision to ensure coaxiality), sealing of tube ends (using ultrasonic welding for plastic fuses or laser sealing for ceramic fuses), and continuity testing (to verify whether the fuse’s current-carrying performance meets standards).Typical applications cover automotive electronics (assembly of miniaturized blade fuses for in-vehicle fuse boxes), consumer electronics (fuse assembly for power adapters and laptop chargers), and industrial control (assembly of high-voltage cartridge fuses for distribution cabinets). Its core advantages include ultra-precise control of electrode spacing (up to ±0.02mm) to ensure consistent fuse blowout current, real-time testing to eliminate defective products (reject rate <0.1%), and modular fixtures that support quick changeover between common fuse specifications (e.g., 5×20mm and 6×30mm) within 15–20 minutes—adapting to the frequent model iterations of electronic products.

Seal and O-Ring Installation EquipmentUsing vacuum suction cups, dedicated grippers, or pneumatic pushers, flexible parts such as O-rings, gaskets, and dust covers are accurately inserted into part grooves. Some equipment is equipped with vision inspection functions to verify whether seals are properly installed (free of twisting or scratches).Main applications include O-ring installation for hydraulic valves (ensuring sealing performance to prevent oil leakage), gasket assembly for water pipe joints (adapting to food-grade sealing materials), and oil seal installation for automotive gearboxes (resisting high temperatures and oil contamination). The advantages of this technology are reduced seal damage caused by manual installation (installation pass rate over 99.5%) and quick fixture replacement to adapt to seals of different sizes, resulting in short changeover times.

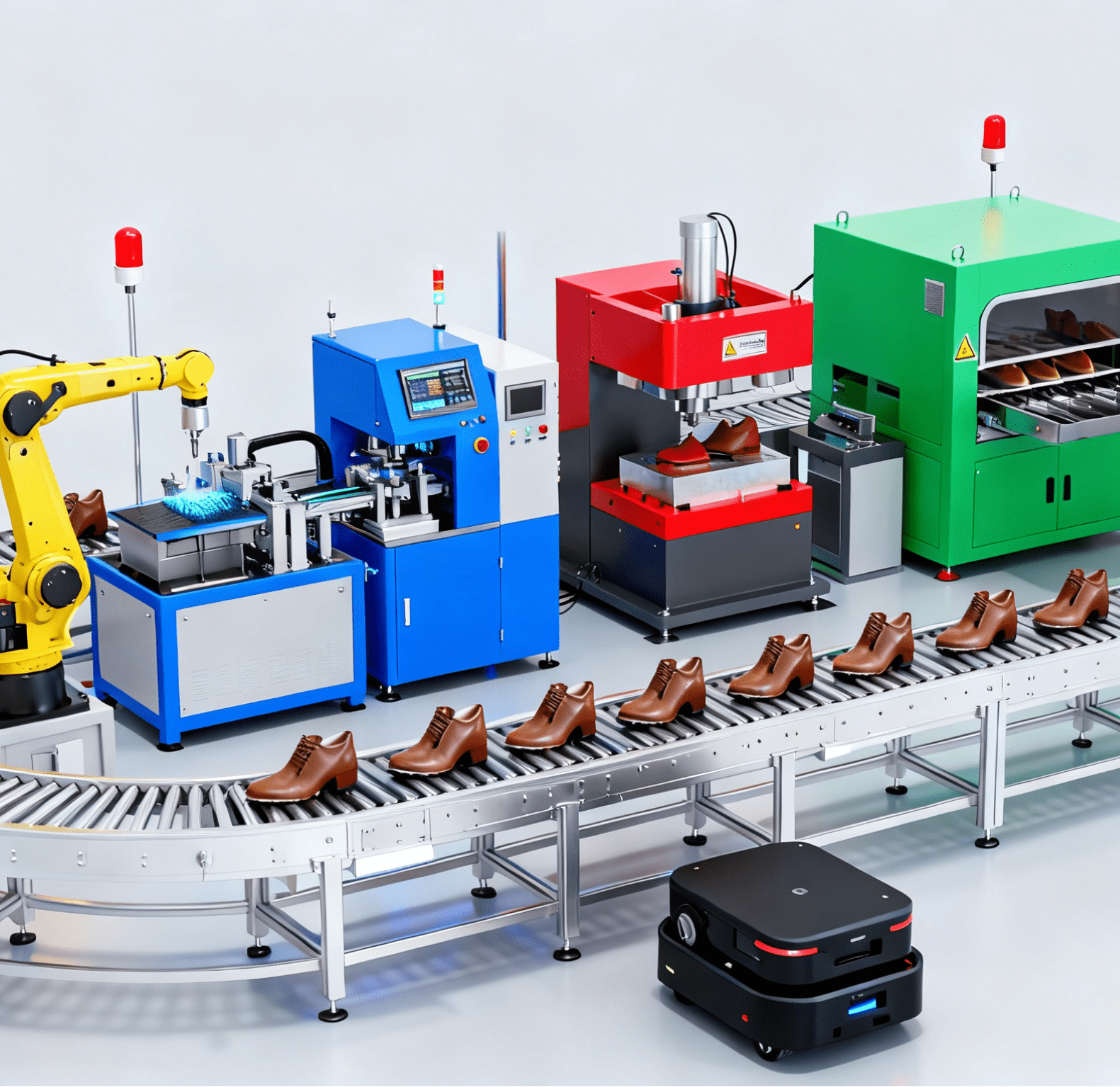

Configuration Schemes and Auxiliary Systems of Automated Assembly Equipment

Equipment configuration directly determines the production efficiency and flexibility of the assembly line. Suitable schemes must be selected based on production rhythm (batch/takt time) and part complexity, while auxiliary systems should be matched to improve overall performance.

Mainstream Configuration Schemes

Turntable System (Rotary Indexing Table): With a circular turntable as the carrier, multiple assembly workstations are evenly distributed along the turntable circumference (e.g., feeding, press-fitting, inspection, unloading). The turntable is driven by a servo motor for intermittent rotation, and one process is completed per rotation. Suitable for small-batch, multi-station assembly of small parts (e.g., micro-motor rotor assembly, relay part assembly). Advantages: small footprint, good process synchronization, production takt of 1–3 seconds per piece, simple structure, and low maintenance costs.

Continuous Motion System: Assembly workstations move continuously along linear or circular tracks, with all workstations operating synchronously (e.g., while parts move at a constant speed on a conveyor belt, robotic arms above complete feeding, assembly, and inspection simultaneously). Suitable for high-speed, large-batch production (e.g., beverage bottle cap assembly, battery cell sorting and assembly). Production efficiency can reach 1,000–2,000 pieces per minute. Disadvantage: low adjustment flexibility—repositioning and parameter adjustment of all workstations are required when changing product specifications.

In-Line Indexing System: Workstations are arranged along a linear track, and workpieces are carried by pallets and moved step-by-step by servo motors (stopping once per workstation to complete the corresponding process). The number of workstations can be increased or decreased based on production needs (e.g., adding inspection or material replenishment workstations). Suitable for medium-sized parts (e.g., automotive instrument panel assembly, home appliance compressor part assembly). Advantages: strong scalability for future capacity improvement, independent control of each workstation, and no impact on the entire production line if one workstation fails.

Asynchronous System (Flexible Conveyor Line): Workpiece pallets are equipped with independent drive units (e.g., AGV carts, electric rollers) and can adjust their movement speed independently based on the progress of each workstation. If a workstation takes longer to assemble, subsequent pallets can be temporarily stored in a buffer area to avoid congestion. Suitable for multi-variety, small-batch production (e.g., customized home appliance part assembly, industrial sensor assembly). Advantages: high flexibility, changeover time reduced to 10–30 minutes, and production processes adjustable via software to adapt to different product assembly needs.

Gantry Transfer System: Composed of gantry robots (gantry beams) and fixed assembly tables, gantry robots move along X, Y, and Z axes to transfer parts across workstations (e.g., grabbing parts from one assembly table to another). Some systems also integrate assembly functions (e.g., robotic arm ends equipped with tightening tools for simultaneous transfer and assembly). Suitable for heavy parts (e.g., automotive frame assembly, large mechanical equipment housing assembly). Advantages: wide coverage (can span multiple workshops), high load capacity (maximum load up to several tons), and no occupation of floor space—facilitating workshop layout.

Key Auxiliary Systems

Machine Vision System: Composed of high-resolution cameras (2D/3D), dedicated light sources (ring lights, bar lights), and image processing software. Its core functions include part positioning (e.g., identifying part angle deviations to guide robotic arm adjustment for grabbing positions), assembly quality inspection (e.g., checking for missing screw tightening, O-ring twisting, or welding pores), and part defect screening (e.g., detecting surface scratches or dimension deviations of parts). For example, in the assembly of mobile phone camera modules, 3D vision systems can accurately identify the relative position of lenses and sensors, correcting deviations to ±0.001mm to ensure imaging quality.

Material Conveying and Storage System: Covers conveyors (timing belts, chain plates, roller conveyors—adapted to parts of different weights), elevators (vertical part conveying to connect assembly lines on different floors), automatic silos (stereoscopic or drawer-type silos for storing parts to be assembled, enabling uninterrupted feeding), and SMD tape feeders (specialized for the electronics industry to accurately convey micro-components such as chips and resistors). For example, in an automotive part production line, AGV carts can automatically transport gearbox housings to be assembled from the warehouse to the assembly workstation, and then transport finished products to the inspection area after assembly—realizing automated material flow.

Testing and Traceability System: Integrates electrical performance testing (e.g., detecting conductivity and insulation resistance of assembled circuit boards), dimension measurement (e.g., laser displacement sensors detecting assembly gaps and coaxiality of parts), and functional testing (e.g., testing the speed of assembled motors or the switching performance of valves). Meanwhile, each part or finished product is assigned a unique identifier via barcode/QR code scanning, recording information such as assembly workstations, operators, equipment parameters, and inspection results to form a full-lifecycle traceability file. For example, in medical equipment assembly, the traceability system can query the assembly time of a syringe and the batch of gaskets used, facilitating quality problem tracing.

Palletizing and Packaging System: After assembly, palletizing robots stack finished products onto pallets according to pre-set patterns (e.g., stacking home appliance parts in layers to avoid collision). They are matched with automatic packaging machines (heat-shrink film packaging machines, carton sealing machines, labeling machines) to complete packaging and marking. For example, at the end of a food packaging equipment assembly line, palletizing robots stack assembled packaging machine bodies, automatic film-wrapping machines perform moisture-proof treatment, and labeling machines attach product models and production dates—realizing integration of “assembly-packaging-storage” and reducing manual handling.

Conclusion

Automated assembly equipment is not only a tool to improve production efficiency but also a core carrier for the manufacturing industry to achieve transformation toward “high quality, high flexibility, and low energy consumption”. Its application scenarios continue to expand—from automotive and electronics to medical care and aerospace—while its technology keeps advancing toward “intelligence, flexibility, and digitalization”.In the future, with the in-depth integration of technologies such as AI and industrial Internet, automated assembly equipment will further break down “equipment silos” and become a key component of smart factories, providing stronger support for the sustainable development of the manufacturing industry.

Automated assembly mechanical connection equipment

Artificial intelligence automated assembly mechanical connection robot