First Industrial-Grade Wheeled Humanoid Robot Debuts on September 12, Focusing on Injection Molding Scenarios to Achieve the Shift from “Capable of Working” to “Skilled in Working” via “Data→AI→Execution” Closed Loop...

On September 12, Guangdong Tusstar Technology Co., Ltd., a smart equipment service provider, officially launched its first humanoid robot product for industrial applications. The wheeled humanoid robot released this time is mainly targeted at the process scenarios of the injection molding industry. Through the closed-loop design of “process data→AI large model→execution”, it realizes the transformation of humanoid robot products from “capable of working” to “skilled in working”, so as to effectively meet the application needs of manufacturing scenarios.

Technical Analysis of X5 Motion Control Platform: Hardware Commercialization Iteration and Multi-Dimensional Support of Software Ecosystem

It is understood that the hardware of Tusstar’s new-generation X5 motion controller for industrial application scenarios has undergone multiple rounds of R&D iterations and achieved reliable commercialization. The underlying software platform has realized virtualization and decoupling of software and hardware, connected to a variety of mainstream artificial intelligence computing power platforms, and provided real-time RGM control interfaces, which offer solid support for AI data collection and application development. The application software platform adopts a cloud-edge-end architecture, opens more than 500 sets of underlying functional interfaces to the outside world, and is deeply integrated with mainstream AI large models and simulation systems. It has realized high-end applications such as vision unregistered guided depalletizing/palletizing, cerebellum-end control of dual-arm robots and wheeled humanoid robots, and end-to-end intelligent assembly.

X5 Platform Empowers Cross-Scenario Implementation: Millisecond-Level Response in Injection Molding and High-Precision Assembly Upgrade of Medical Syringes

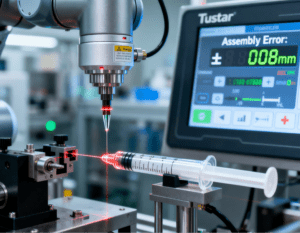

Based on the new-generation X5 robot motion control platform, Tusstar has built an intelligent collaborative system of “VR+AI+Industrial Robot” and created an intelligent dual-arm robot solution. This solution can not only achieve millisecond-level real-time response for multi-axis linkage in injection molding scenarios, but also support the upgrade of Syringe Automatic Assembly Equipment in the production of medical consumables across fields. Relying on the high-precision force control algorithm and AI visual positioning capability of the X5 platform, it accurately completes the coaxial alignment of syringe needles and barrels, rubber plug pressing, and syringe tightness testing, controlling the assembly error of a single set within ±0.01mm. At the same time, it uploads assembly data in real time through the cloud-edge-end architecture, realizing rapid parameter switching for syringes of different specifications (such as 1ml, 5ml, 10ml), and meeting the strict requirements of the medical industry for asepsis, high precision, and flexible production. In addition, the teleoperation capability realized based on the high-precision force feedback handle can also remotely debug the assembly process and reduce the pollution risk caused by manual intervention.

“Specialized + General-Purpose” Dual-Track Collaboration: Linking Existing Robotic Arms to Enter the 100-Billion-Level Pan-Manufacturing Automation Market

This humanoid robot will collaborate with existing robotic arm products to form a “specialized + general-purpose” dual-track solution, entering the 100-billion-level pan-manufacturing automation market and building a blue ocean field that collaborates with the embodied intelligent robot industry amid the red ocean competition.