In the bath

room hardware industry, where user experience and product safety are paramount, the toilet seat cover stands out as a daily-use item whose quality directly impacts comfort and safety. A common yet critical flaw in traditional toilet seat production—sharp edges and burrs—has long plagued manufacturers: these tiny, rough protrusions not only ruin the product’s sleek appearance but also pose a risk of scratching users’ skin. For decades, manufacturers relied on manual deburring, a labor-intensive process that struggled to balance efficiency, precision, and consistency. Today, the Automatic Deburring Machine for Toilet Seat Covers has emerged as a game-changer, addressing industry pain points while aligning with the global trend of intelligent, automated manufacturing.

Why Automatic Deburring? The Pain Points of Traditional Processes

Before the advent of specialized automation, toilet seat cover deburring was dominated by two manual methods: hand sanding with abrasive tools and manual grinding with small electric machines. Both approaches came with inherent limitations:

Low efficiency: A skilled worker could only process 30–50 toilet seat covers per day, struggling to keep up with large-scale production demands.

Inconsistent precision: Deburring quality depended entirely on the worker’s experience—too little grinding left burrs intact, while over-grinding damaged the seat’s edge contour, leading to a 5–8% product defect rate.

High labor costs: Skilled deburring workers required extensive training, and long hours of repetitive work led to high turnover rates, increasing recruitment and training expenses for manufacturers.

Safety risks: Manual operation exposed workers to abrasive dust and repetitive strain injuries (RSIs), raising occupational health concerns.

As consumers demand higher-quality bathroom products and manufacturers pursue lean production, the need for a more reliable, efficient deburring solution became urgent—and the Automatic Deburring Machine for Toilet Seat Covers filled this gap.

Core Technologies: How Automatic Deburring Machines Elevate Production

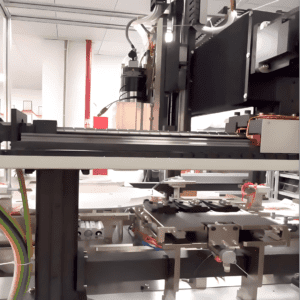

Modern Automatic Deburring Machines for Toilet Seat Covers integrate multiple advanced technologies to adapt to the diverse characteristics of toilet seat materials (ceramic, resin, acrylic, and solid wood composite) and shapes (U-type, O-type, and custom contours). Their key features include:

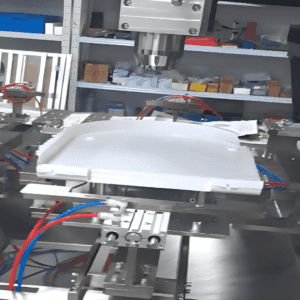

- Intelligent Material & Contour Recognition

Equipped with high-resolution industrial cameras and AI visual positioning systems, the machine first scans the toilet seat cover to identify its material, shape, and burr distribution. For example, for brittle ceramic seats, it automatically adjusts to a gentler grinding pressure; for flexible resin seats, it optimizes the grinding speed to avoid deformation. The visual system achieves a positioning accuracy of ±0.02mm, ensuring no burrs are missed and no valid edge is damaged.

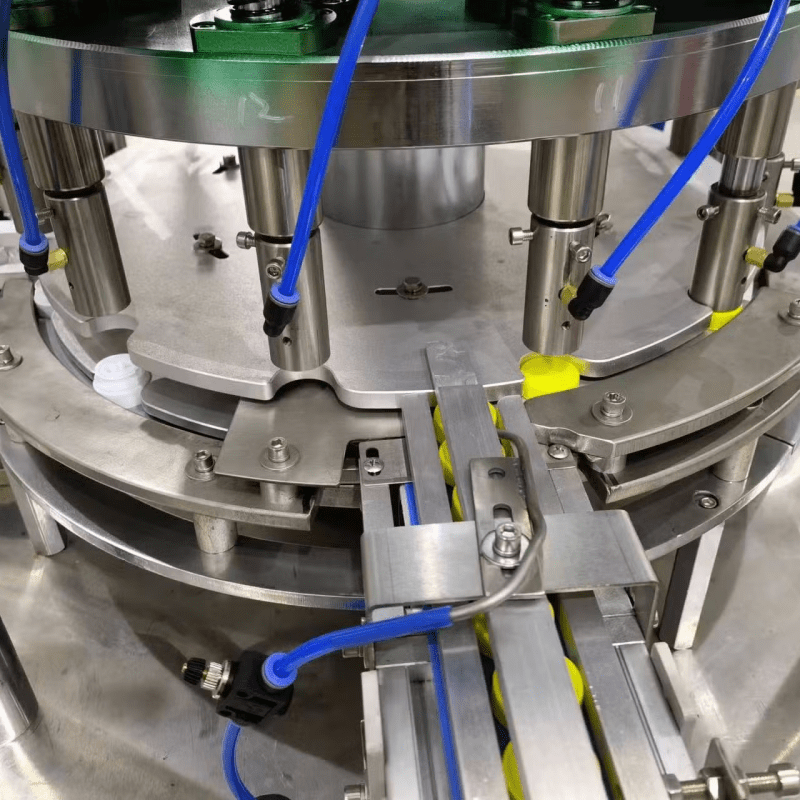

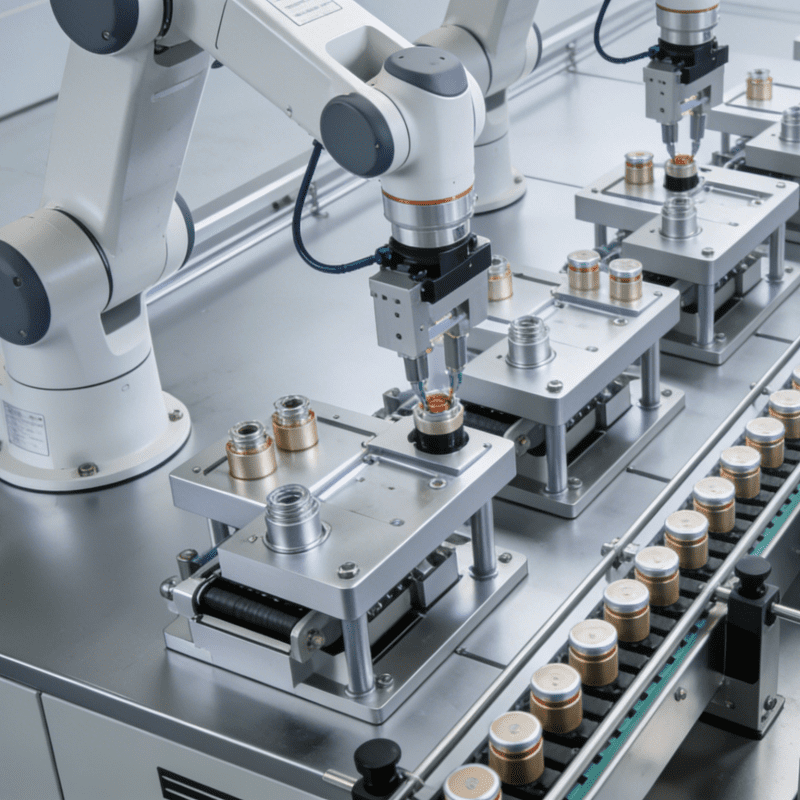

- Multi-Axis Linkage & Adaptive Deburring

Unlike fixed-path manual grinding, the machine uses 4–6 axis robotic arms to mimic the flexibility of human hands—yet with far greater precision. The arms are fitted with replaceable deburring tools (abrasive belts, nylon brushes, and diamond grinders) that switch automatically based on the burr type:

Abrasive belts for removing large, hard burrs on ceramic seat edges;

Nylon brushes for polishing fine burrs on resin seats without leaving scratches;

Diamond grinders for shaping and deburring solid wood composite seats, preserving their natural texture.

The machine’s adaptive algorithm also adjusts the grinding force in real time: when encountering thicker burrs, it increases pressure slightly; when moving to smooth areas, it reduces force to prevent over-processing.

- Dust Collection & Environmental Protection

To solve the problem of abrasive dust pollution in manual workshops, the machine is integrated with a high-negative-pressure dust collection system. As the deburring process proceeds, a hood above the workbench suctions dust into a filter chamber, achieving a dust collection rate of over 95%. This not only meets national workshop air quality standards but also reduces equipment maintenance costs (dust accumulation on mechanical parts is a major cause of breakdowns).

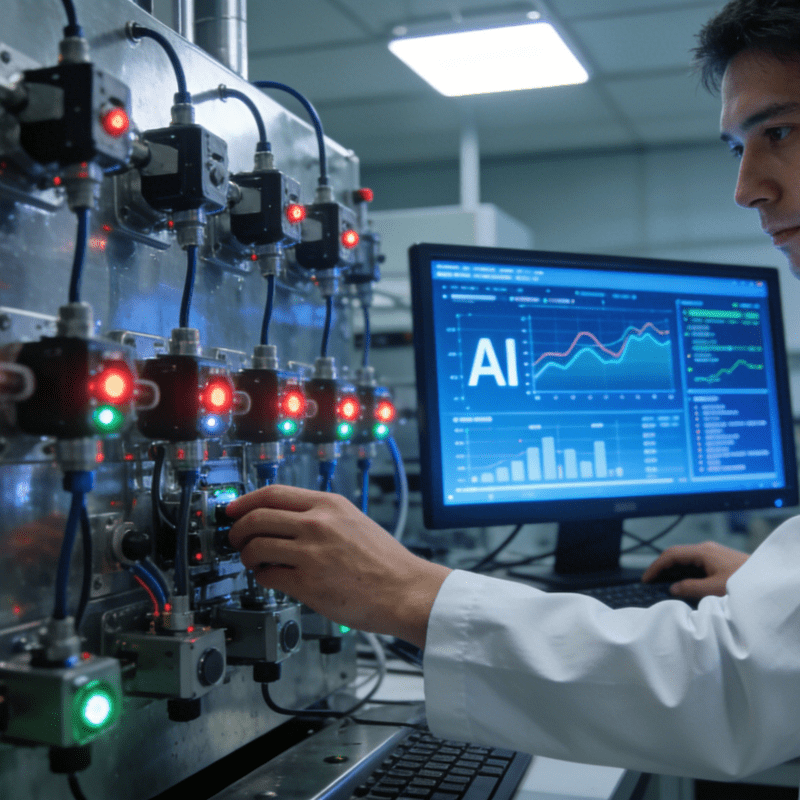

- Data Integration & Smart Management

Most modern models support connection to a factory’s MES (Manufacturing Execution System). Through real-time data transmission, managers can monitor key metrics such as:

Number of processed seats per hour (typically 120–150, 3x higher than manual);

Deburring defect rate (reduced to below 0.5%);

Tool wear status (the system alerts maintenance teams when tools need replacement).

This data-driven management helps manufacturers optimize production schedules and reduce unplanned downtime.

Real-World Impact: A Case Study from a Leading Bathroom Brand

A top-5 global bathroom hardware manufacturer specializing in smart toilets recently replaced 20 manual deburring workstations with 5 Automatic Deburring Machines for Toilet Seat Covers. Within three months, the results were striking:

Production efficiency: Daily output of toilet seat covers increased from 800 to 2,200, meeting the brand’s growing demand for overseas markets.

Quality improvement: Defect rate due to burrs dropped from 7.2% to 0.3%, reducing product returns and enhancing brand reputation.

Cost savings: Labor costs for deburring decreased by 60%, and dust-related equipment maintenance costs fell by 40%.

As the plant manager noted: “The automatic deburring machine doesn’t just replace workers—it elevates our entire production line to a more precise, sustainable level. We no longer worry about inconsistent quality or missed deadlines.”

Future Trends: Toward More Intelligent, Eco-Friendly Deburring

As bathroom hardware manufacturing becomes more intelligent and eco-conscious, Automatic Deburring Machines for Toilet Seat Covers are poised to evolve further:

AI-driven process optimization: Future models will use machine learning to analyze historical deburring data, automatically optimizing grinding paths and parameters for new toilet seat designs—eliminating the need for manual parameter setup.

Eco-friendly materials adaptation: With the rise of biodegradable resin and recycled plastic toilet seats, machines will be upgraded to handle these softer, more fragile materials without compromising efficiency.

Miniaturization for custom production: For high-end, custom-designed toilet seats (e.g., for luxury hotels or accessible bathrooms), compact automatic deburring machines with flexible robotic arms will enable small-batch, high-precision processing.

In conclusion, the Automatic Deburring Machine for Toilet Seat Covers is more than just a piece of equipment—it is a catalyst for transforming the bathroom hardware industry from labor-intensive to technology-driven. By solving long-standing pain points of inefficiency, inconsistency, and high costs, it helps manufacturers deliver safer, more high-quality products while laying the groundwork for a smarter, more sustainable future of production. For any brand aiming to stay competitive in the global bathroom market, investing in this technology is no longer an option—it is a necessity.