Introduction: Core Challenges in the Resource Utilization of Industrial Solid Waste

Multi-source industrial solid wastes, including steel slag, blast furnace slag, and phosphogypsum, are mainly composed of calcium-magnesium-silicon-aluminum-based minerals with potential hydration and gelling activity. During the resource utilization of these solid wastes, multiple difficulties must be overcome, such as wide distribution of raw material sources, large fluctuations in composition, high content of inert components, complex associated material phases, and great difficulty in activation.

Basic Project Information

Project Name: Development and Application Demonstration of a Multi-Path Industrial Solid Waste-Based Ecological Carbon Sequestration System

Project Number: HJJS-2024-2-17

Award Level: Second Prize of Environmental Technology Progress Award

Completing Institutions: Hubei University, Hubei Water Resources and Hydropower Science Research Institute, Hubei Ecological and Environmental Monitoring Center Station, Wuhan University of Technology, Anhui University of Technology, CCCC Second Harbor Engineering Co., Ltd., Wuhan Zhiyuan Construction Group Co., Ltd.

Completing Individuals: Zhu Shujing, Zhou Nianlai, Liu Zhenzhen, Yu Jiang, Zhang Guozhi, Zhou Chi, Li Bailin, Li Canhua, Zhu Zunqun, Tan Lin, Li Ye, Chen Wenfeng, Su Qi, Wang Lilin

Project Overview: Dual Dilemmas in Industrial Solid Waste Management in Hubei

Hubei Province is an important industrial base in China, with extensive sources and huge output of industrial solid waste. The safe disposal of these wastes is directly related to the ecological and environmental security of the province. Currently, the “zero-waste development” of industrial cities and ecological environment governance face two major challenges: (1) The key technologies and development space for the localized treatment of bulk solid waste are limited; (2) The ecological governance efficiency of typical environmental sediments is low. Therefore, there is an urgent need to develop in-situ ecological governance technologies for typical environmental sediments based on the resource utilization of industrial solid waste.

Core Technology: Paths for Solid Waste Resource Utilization Under Dual-Efficiency Synergy

Technological Background and Breakthrough Directions

Multi-source industrial solid wastes, including steel slag, blast furnace slag, and phosphogypsum, are mainly composed of calcium-magnesium-silicon-aluminum-based minerals with potential hydration and gelling activity. During the resource utilization of these solid wastes, multiple difficulties must be overcome, such as wide distribution of raw material sources, large fluctuations in composition, high content of inert components, complex associated material phases, and great difficulty in activation. To address these issues, this technology is based on the dual-efficiency synergy principle of “resource circulation and pollution control”. It breaks through the bottleneck of synergistic implementation of environmental pollution control and ecological carbon reduction at three levels: key material design and compatibility, application practice in typical scenarios, and technology refinement and industry demonstration. A key technical theoretical system for the industrial solid waste-based ecological carbon sequestration system has been formed, and demonstration applications in typical scenarios have been carried out.

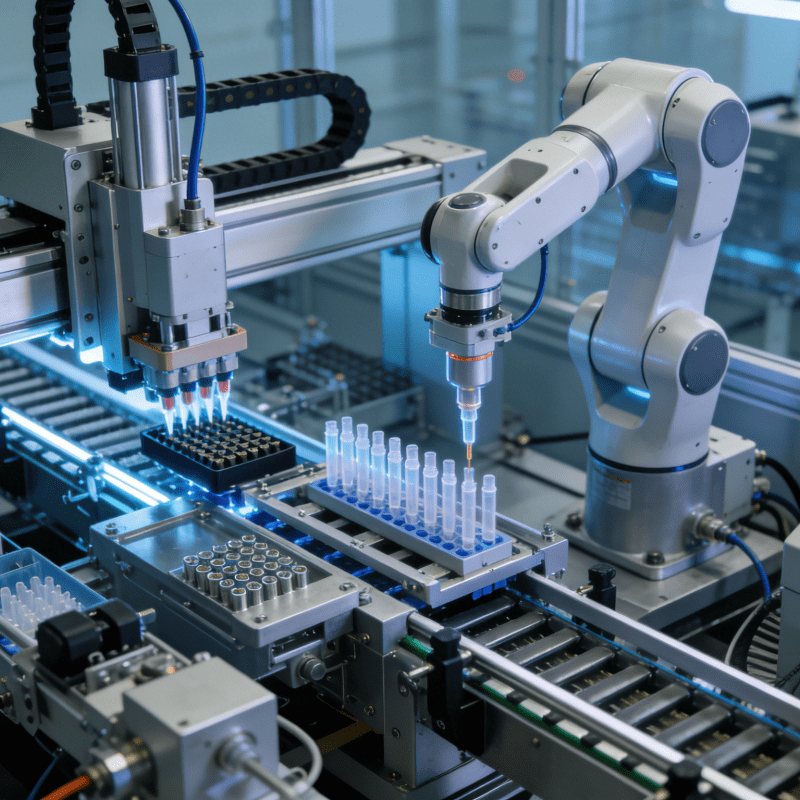

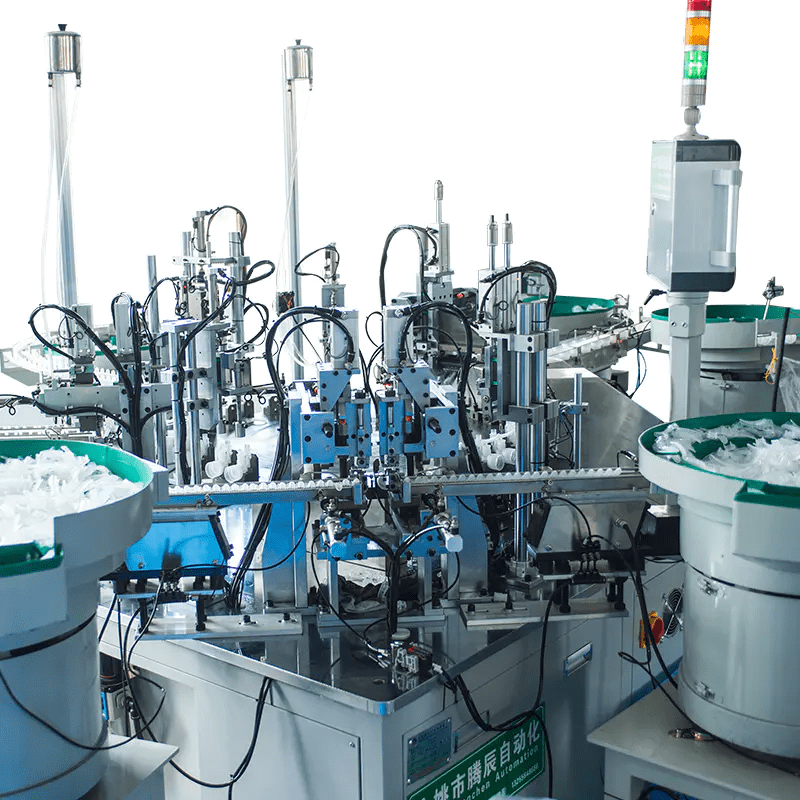

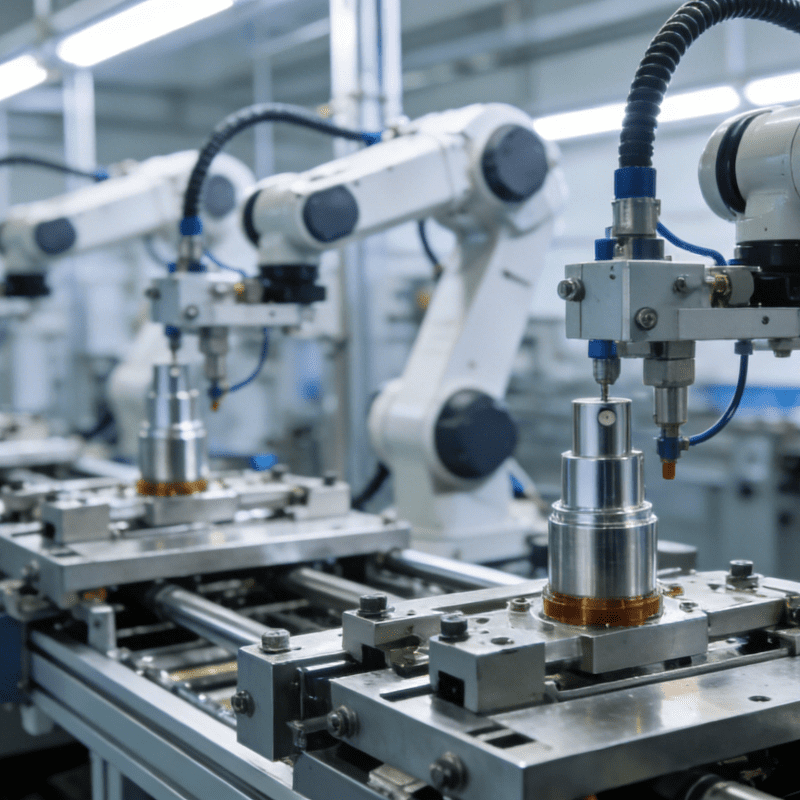

It is worth noting that the innovative logic of industrial solid waste resource utilization technology is also gradually penetrating into the field of high-end manufacturing. For example, the Biztosíték összeszerelő gép used in electronic component production has begun to try applying industrial solid waste-derived materials processed by the technology of this project (such as steel slag-based wear-resistant alloy components and slag-based insulating composite materials) to the manufacturing of core structural parts of equipment. This not only reduces the dependence of equipment production on primary metals and polymer materials but also improves the operational stability of the assembly machine through the high strength and high insulation properties of solid waste-derived materials, controlling the fuse assembly accuracy error within ±0.02mm. At the same time, it realizes cross-field synergy of “industrial solid waste resource utilization – cost reduction of high-end equipment – low-carbon production”, opening up new scenarios for the high-value utilization of industrial solid waste.

Key Inventions: Two Core Technological Innovations

Invention 1: Design and Process Breakthroughs of Carbon Sequestration Primitive Materials

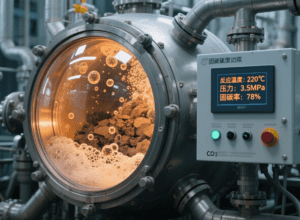

Innovation in the compatibility design and processing technology of multi-source industrial solid waste-based carbon sequestration primitive materials. Based on the peridynamics theory, by combining mechanical force and chemical modification methods, a new design concept for homogenization treatment, compatibility regulation, and efficiency synergy of environmental materials with complex phases and multiple types is proposed. A primitive material design method and its processing technology for constructing ecological carbon sequestration systems using multi-source industrial solid wastes (steel slag, blast furnace slag, phosphogypsum, etc.) have been invented.

Invention 2: Construction of Ecological Carbon Sequestration Systems and Characterization of Carbon Sink Pathways

Construction of typical ecological carbon sequestration systems and characterization of their carbon sink pathways. Aiming at the process twin attributes of environmental sediment pollution control and wetland carbon sink, and considering the synergy principle of pollution control and resource utilization, three typical ecological carbon sequestration system prototypes (high liquid phase: underwater sealed, high water content: soil-water mutual immersion, high carbon content: gas-solid integration) are proposed and applied in demonstration projects. A key technical system for the ecological governance of typical environmental sediments has been constructed, and its carbon sink pathways have been initially characterized. This provides three implementable technical pathways (“terrestrial, underwater, and engineering”) for China’s carbon neutrality strategy.

Project Achievements: Multi-Dimensional Outputs of Technologies and Standards

The project has obtained 31 national invention patents, formulated 17 national and provincial construction methods, provincial and municipal technical specifications, and enterprise product standards (including the Technical Specification for River and Lake Ecological Dredging Engineering DB13/T5606-2022), and published 38 papers, among which 10 are included in SCI. Appraised by a third-party organization, the research results have generally reached the international advanced level, and the low-alkalinity sludge solidifier has reached the international leading level.

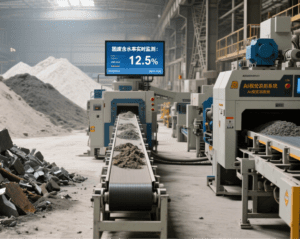

Assembly line for mass production by artificial intelligence