Intelligent Conveyors Transform Medical Device Manufacturing

In industries where precision, regulatory compliance, and space optimization are non-negotiable, innovative automation solutions are reshaping production landscapes. Just as Bathroom Fixture Assembly Equipment must balance efficiency with meticulous component handling in limited factory spaces, medical device manufacturers face parallel challenges in scaling production within cleanroom environments. Enter intelligent conveyors—a technology driving transformative gains in both sectors. Let’s explore how Rockwell Automation’s MagneMover Lite is revolutionizing medical device assembly, with lessons with broader implications for industries like bathroom fixture manufacturing.

The demand for medical devices, from wearable monitors to smart drug delivery systems, has never been higher. Yet, scaling production in regulated cleanroom settings is fraught with hurdles: limited space, FDA validation requirements, and the need for extreme precision in processes like wire bending and epoxy dispensing. For one manufacturer, traditional belt-driven conveyors posed bottlenecks: inflexible routing, shared cycle times, and a bulky footprint. These challenges mirror those in Bathroom Fixture Assembly Equipment, where modularity and space efficiency are critical for assembling components like faucets or shower systems with varying specifications.

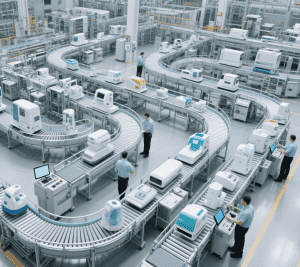

Automation NTH initially addressed the medical manufacturer’s needs with a validated, modular system using belt conveyors. But as production scaled, the limitations became clear: fixed workflows couldn’t adapt to real-time demand, and the conveyor’s size constrained cleanroom capacity. The solution? Rockwell Automation’s MagneMover Lite—an intelligent conveyor system using magnetically propelled carriers that move independently. This technology, akin to the adaptive transport systems in Bathroom Fixture Assembly Equipment, allows dynamic routing of parts based on production needs, bypassing stations as required and enabling “lot-size-one” flexibility.

Key to the integration was Automation NTH’s proprietary software engine, which interfaces with MagneMover Lite to control carrier speed, acceleration, and station assignments. The result? A compact, flexible system that supports both fully automated and hybrid (manual-robotic) assembly—much like how Bathroom Fixture Assembly Equipment must accommodate diverse assembly methods for different product lines. Critically, the system preserved the manufacturer’s validated processes while eliminating the inefficiencies of traditional conveyors.

The impact was dramatic: production speed and capacity doubled within the same footprint, cost per part dropped 40%, and the system’s footprint shrank by 38%. For medical device makers, these gains translate to higher accessibility of life-saving products; for industries like bathroom fixture manufacturing, they offer a blueprint for optimizing space and cost in assembly lines for sinks, toilets, or complex shower systems.

The success of MagneMover Lite in medical devices underscores a broader truth: intelligent, flexible automation is the key to overcoming spatial and regulatory constraints. In medical manufacturing, it’s about meeting FDA standards while scaling; in bathroom fixture assembly, it’s about producing diverse products (from minimalist faucets to smart shower systems) efficiently in limited factory spaces. Both industries benefit from technologies that prioritize adaptability—whether through independent carrier movement in conveyors or modular tooling in Bathroom Fixture Assembly Equipment.

As manufacturers across sectors grapple with rising demand and operational costs, the lesson is clear: investing in intelligent, space-saving solutions like MagneMover Lite or modular assembly equipment can deliver exponential returns. For medical devices, it’s a matter of patient care; for bathroom fixtures, it’s about meeting consumer preferences for variety and quality. In either case, the future of assembly lies in systems that blend precision, flexibility, and innovation—proving that even in vastly different industries, the pursuit of efficient, scalable production unites us all.