In life science experiments, the precision of reagent dispenser components directly impacts the accuracy of experimental data. For medical devices, such as minimally invasive surgical instruments, the precision of their cutting edges is critical to patient safety during surgery. The manufacturing quality of these core components is a key factor for the competitiveness of the life science and medical industries.

However, traditional grinding methods often suffer from excessive dimensional errors, especially for parts with complex curved surfaces where manual operations struggle to ensure consistency. Additionally, when processing hard materials like ceramics or cemented carbide, conventional equipment tends to cause uneven wear of the grinding wheel, leading to non-compliant surface roughness of the finished parts. How can we break through these processing bottlenecks to achieve the manufacturing of parts with high precision and consistency? Grinding technology is precisely the key solution to address these challenges.

Basic Principles and Core Definition of Grinding Technology

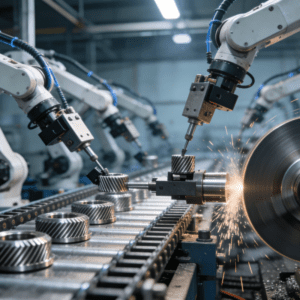

Grinding technology is a precision machining technique that utilizes a numerical control system to accurately control the relative movement trajectory and parameters between the grinding wheel and the workpiece, thereby achieving high-precision grinding of the workpiece surface. Unlike traditional grinding processes that rely on manual adjustment of the grinding wheel position and feed rate, grinding technology automatically completes the machining process through pre-programmed instructions. This approach minimizes the impact of human errors, enabling stable machining with precision down to the micrometer level or even higher. Its core lies in converting complex machining paths into digital instructions, which drive the equipment to perform precise movements, ensuring consistent machining quality across all parts.

Industry Pain Points Solved and Core Roles of Grinding Technology

Traditional grinding methods face three major pain points when processing high-precision parts:

Precision Control: Dimensional accuracy is difficult to maintain, especially for small-batch, multi-variety part processing, where errors tend to accumulate.

Processing Difficulty: Complex curved and irregularly shaped parts are challenging to process, and manual operations cannot guarantee smooth transitions of curved surfaces.

Processing Efficiency: The efficiency of processing hard materials such as cemented carbide and ceramics is low, while the grinding wheel wears out quickly, increasing production costs.

Grinding technology effectively addresses these issues by:

Achieving high-precision machining of complex-shaped parts through precise digital control.

Automating the machining process to improve the efficiency of processing hard materials while reducing unnecessary wear of the grinding wheel.

Ensuring consistent part dimensions through stable processing parameters, thereby reducing the defect rate.

Key Advantages of Grinding Technology

Grinding technology boasts several key advantages that make it the preferred choice for high-precision part manufacturing:

High Precision: It can achieve dimensional accuracy of ±0.01 mm and surface roughness of Ra 0.05 μm, meeting the strict requirements of life science and medical equipment accessories.

High Automation: The equipment can automatically complete loading, machining, and inspection processes through pre-set programs, reducing manual intervention and improving production efficiency.

Versatility: It can adapt to the processing needs of various types of parts, including flat surfaces, cylindrical surfaces, and curved surfaces.

Stability: The equipment features excellent stability, maintaining precision even during long-term continuous operation.

Furthermore, the grinding equipment is highly automated, capable of completing the entire machining process through pre-programmed instructions. Its core components, such as high-precision guides and servo motors, are made of durable materials with a long service life. The R&D team of enterprises continuously optimizes equipment performance, developing specialized processes tailored to the specific needs of the life science and medical fields.

Main Application Fields of Grinding Technology

Grinding technology is widely used across multiple industries, particularly playing a crucial role in the life science and medical equipment sectors.

Life Science Field: It is used to process precision pistons of reagent dispensers, high-precision fixtures for experimental equipment, and other components, ensuring the accuracy of experimental data.

Medical Equipment Field: It can process the cutting edges of minimally invasive surgical tools and the surface treatment of implanted devices, ensuring the safety and reliability of medical equipment.

Other Industries: It is also applied in automotive manufacturing (e.g., precision grinding of engine valves), mold manufacturing (e.g., processing of high-precision mold cavities), and the electronics industry (e.g., processing of packaging parts for semiconductor chips). According to industry reports, the global market size of grinding equipment is expected to reach $32 billion by 2025, with the demand in the medical and life science sectors growing at an annual rate of over 15%, reflecting its sustained growth potential in the field of high-precision manufacturing.

Market Prospects and Industry Trends of Grinding Technology

With the rapid development of the life science and medical equipment industries, the demand for high-precision parts is increasing, creating broad market prospects for grinding technology. In the future, grinding technology will develop in the directions of intelligence and customization:

Intelligence: Combining artificial intelligence technology to optimize processing parameters, enabling real-time adjustments to meet the processing requirements of different materials.

Customization: Developing specialized equipment and processes for the specific needs of different industries, such as sterile processing technology for the life science sector and specialized grinding solutions for minimally invasive surgical tools in the medical equipment field.

For enterprises, upgrading to grinding equipment not only improves product quality but also enhances market competitiveness, adapting to the development trends of the industry.

Conclusion

As a core technology for high-precision manufacturing, grinding technology plays an irreplaceable role in solving the pain points of traditional processing and improving part quality. Its wide range of applications and growing market demand make it a crucial choice for enterprises in the life science and medical equipment accessory manufacturing sectors. By adopting grinding technology, enterprises can achieve higher-precision and more efficient part processing, meeting the strict requirements of the industry and driving the development of their own businesses.