Table of Contents

ToggleCUniversal Assembly System: Redefining Flexibility in Smart Manufacturing Automation

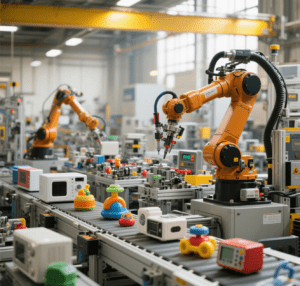

In the era of mass customization, traditional assembly systems struggle to keep pace with rapidly evolving product demands. Characterized by rigid workflows and lengthy retooling times (20–40 hours per product change), these systems fail to address the needs of high-mix, low-volume production. The CUniversal Assembly System emerges as a transformative solution, integrating modular robotics, AI-driven vision, and adaptive control to enable seamless reconfiguration across diverse industries—from automotive to electronics. This article explores its technical architecture, industrial applications, and role in shaping the future of agile manufacturing.

I. Core Technical Architecture: Modularity Meets Intelligence

The system’s design prioritizes flexibility through four interdependent subsystems:

1. Multi-Robot Collaborative Units

Powered by 6-axis industrial robots (e.g., Fanuc CRX-25iA) and SCARA robots (Yamaha YK-XG), the system offers:

- Hybrid Robot Teams: 6-axis robots handle complex 3D assembly (±0.02mm precision), while SCARA robots excel in high-speed planar tasks (150+ picks/minute);

- Quick-Change Tooling: Modular grippers (vacuum, pneumatic, magnetic) swap in <10 seconds, supporting diverse parts from 0.1mm micro-sensors to 50kg automotive components;

- Force-Torque Sensing: Real-time feedback (0.1–50N) prevents over-tightening in delicate assemblies like medical devices.

2. AI-Vision Guided Alignment

A dual-modal vision system ensures sub-millimeter accuracy:

- Structured Light 3D Scanning: Reconstructs complex part geometries (e.g., curved surfaces) with 0.01mm resolution, correcting ±15mm positional deviations;

- Deep Learning Part Recognition: YOLOv8-based algorithms identify 500+ part types with 99.9% accuracy, enabling autonomous tooling adjustments;

- Dynamic Calibration: Adapts to conveyor speed (up to 2m/s) using predictive control, ensuring smooth assembly on moving lines.

3. Adaptive Conveyor Networks

- Modular Track Systems: V-shaped and flat belts reconfigure in <30 minutes for different part sizes, with RFID tracking with real-time location updates;

- AGV Integration: Autonomous carts synchronize with assembly cells, enabling flexible production layouts without fixed conveyors;

4. Digital Control Ecosystem

Powered by a PC-based controller with MES integration:

- Recipe Management: Stores 1,000+ assembly protocols for one-click activation, reducing changeover time to <5 minutes;

- Digital Twin Optimization: Simulates assembly processes to minimize robot travel distance by 30%, boosting OEE by 25%;

II. Industrial Applications: From Prototyping to Mass Production

1. Electronics & Wearables

- Smartwatch Assembly: Vacuum grippers handle 0.5mm LCD connectors with ±0.05mm alignment, while AI detects micro-cracks in glass components;

- PCB Component Placement: SCARA robots place 01005-sized resistors (0.4mm×0.2mm) at 200+ components/minute, with ESD-protected tooling.

Case Study: A leading wearable tech firm reduced NPI (new product introduction) time by 60% using the system, enabling weekly product iterations.

2. Automotive E-Powertrain

- Electric Motor Assembly: 6-axis robots install stator windings with ±0.1mm precision, while force control ensures optimal magnetic alignment;

- Battery Pack Integration: Modular grippers handle diverse cell sizes (18650 to prismatic), with vision verifying solder joint quality in real time.

3. Medical Device Manufacturing

- Syringe Pump Assembly: 316L stainless steel grippers and ISO 8 cleanroom coatings meet GMP standards, with traceability software recording every component’s placement;

- Implantable Device Bonding: Micro-grippers apply 0.1N force for delicate adhesive dispensing on sub-1mm components, ensuring hermetic seals.

III. Competitive Advantages Over Traditional Systems

| Metric | Rigid Assembly Line | CUniversal Assembly System |

| Changeover Time | 20–40 hours | <5 minutes (recipe-based) |

| Part Variety Support | 5–10 types | 1,000+ types |

| Prototyping Cost | $50k–$100k per product | 40% lower (modular reconfiguration) |

| Labor Efficiency | 2–3 operators/cell | 0.5 supervisors/remote |

IV. Future Innovations

- AI-Driven Self-optimization: ML models analyze 1M+ assembly cycles to predict tool wear (92% accuracy) and optimize path planning;

- 5G-Enabled Remote Collaboration: AR glasses allow engineers to debug systems via live 3D models, reducing onsite visits by 70%;

Conclusion

The CUniversal Assembly System transcends traditional automation, serving as a cornerstone of agile manufacturing. Its modular design, AI vision, and rapid reconfiguration capabilities dismantle the barriers between mass production and customization. As Industry 4.0 progresses, these systems will evolve into self-adapting ecosystems, enabling manufacturers to thrive in an era where product variety and speed are non-negotiable.

#Univerzális összeszerelő rendszer #Modular Robotics Automation #AI-Vision Guided Assembly