Table of Contents

ToggleAI automatizálási piacvezetők: Németország terve az intelligens és ipari automatizálás integrációjára

Germany’s dominance in industrial automation has long been a cornerstone of its manufacturing might, but today, the nation is rewriting the playbook for intelligent automation. As other countries fixate on robotic process automation, German enterprises are blending AI with industrial-grade precision—powered by homegrown automation equipment and software—to create a new standard for efficiency. Having advised leading German firms on scaling AI-driven workflows, I’ve witnessed firsthand how the country’s industrial heritage, coupled with cutting-edge AI, is reshaping global competitiveness.

Three Pillars of AI-Driven Automation Excellence

German market leaders have honed three strategies to extract maximum value from intelligent automation, seamlessly integrating it with existing industrial automation ecosystems:

1. End-to-End Process Orchestration: Where AI Meets Industrial Discipline

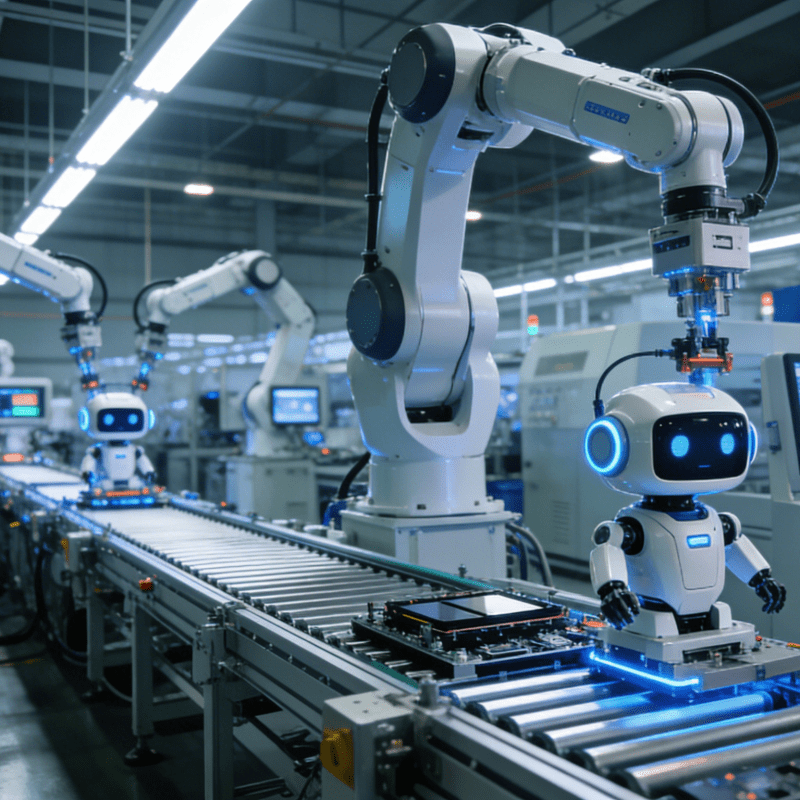

Traditional industrial workflows—from supply chain management to production scheduling—are being reimagined through intelligent automation platforms. These systems stitch together siloed processes, such as:

- Automating invoice approvals in finance while syncing with manufacturing’s raw material orders, a process that relies on industrial automation protocols.

- Using AI to predict maintenance needs for automation equipment like robotic arms, reducing downtime by up to 80% in automotive plants.

The result? Near-flawless compliance and a shift from manual data entry to strategic oversight, enabled by systems that respect Germany’s industrial automation legacy.

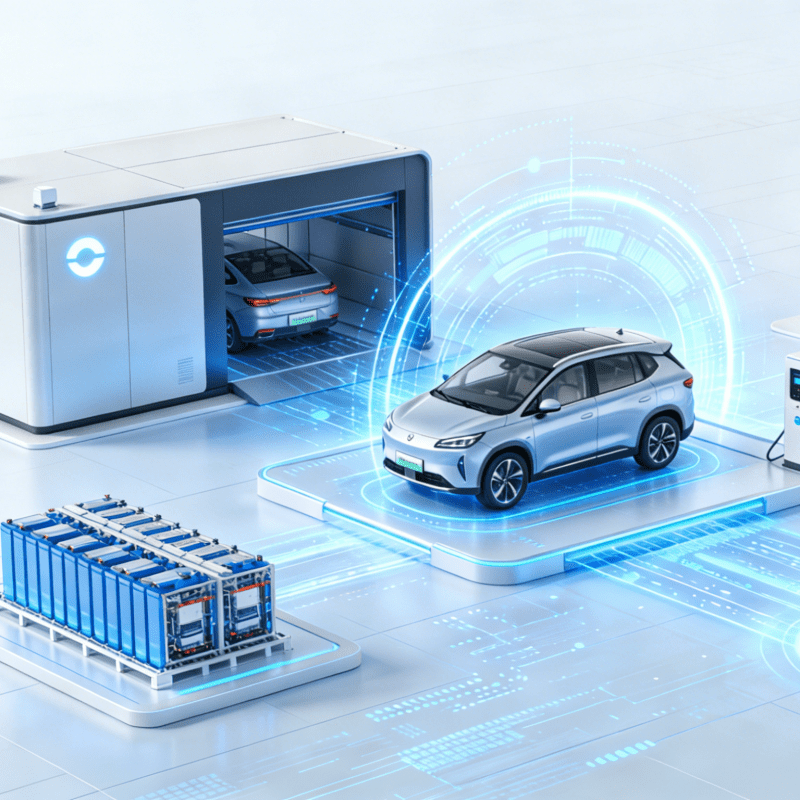

2. Operational Efficiency: From Factory Floors to Digital Frontiers

German industries are leveraging AI to optimize both physical and digital operations:

- Manufacturing: A process-mining tool used by a premium automaker automated quality checks on assembly lines, cutting defect resolution time by 60% by integrating with existing industrial automation systems.

- Energy: A solar firm deployed voice-enabled AI workflows to manage customer outreach, re-engaging leads without adding staff—all while syncing with smart grid automation equipment.

- Telecom: An AI reasoning platform reduced ticket routing costs by 40%, aligning with Germany’s rigorous standards for telecom infrastructure automation.

3. Innovation Through Automated Services

German brands are using AI automation to launch new services that blend industrial precision with digital agility:

- E-commerce giants deploy multilingual AI chatbots that interface with warehouse automation equipment, ensuring order fulfillment speeds match customer expectations.

- Banks use AI for instant KYC checks, integrating with legacy core banking systems—a nod to Germany’s focus on seamless industrial automation integration.

Overcoming Barriers: Germany’s Playbook for Scalable Automation

Implementing AI at scale requires navigating challenges unique to industrialized economies:

1. Data Privacy in Industrial Ecosystems

Under GDPR, AI systems handling production data (e.g., sensor feeds from automation equipment) must embed “privacy by design.” German firms lead in:

- Encrypting data from industrial IoT devices.

- Using explainable AI to audit automation workflows, critical for maintaining trust in manufacturing environments.

2. Legacy Integration: The Industrial Automation Bridge

Many German factories still rely on decades-old PLC systems. Success hinges on:

- Robust APIs that connect modern AI platforms to legacy industrial automation systems.

- Phased rollouts, such as piloting AI in quality control before scaling to full production lines.

3. Talent: Bridging Industrial and Digital Skills

German companies build cross-functional teams that:

- Pair robotics engineers (experts in industrial automation) with data scientists.

- Train factory workers to collaborate with AI systems, not replace them—essential for maintaining Germany’s skilled labor edge.

The Future: Where Intelligent and Industrial Automation Converge

German market leaders prove that AI automation isn’t about replacing industrial might, but enhancing it. By:

- Investing in Automation Ecosystems: Building AI centers of excellence that partner with automation equipment manufacturers like Siemens and FANUC.

- Prioritizing Trust: Publishing AI ethics guidelines for industrial use cases, from autonomous forklifts to predictive maintenance.

- Fostering Ecosystem Collaboration: Working with startups to develop AI tools tailored for industrial automation, such as computer vision systems for quality control.

Germany’s path shows that the future belongs to those who blend the precision of industrial automation with the agility of intelligent systems. As automation equipment becomes smarter and AI becomes more industrialized, the country’s approach offers a blueprint for any enterprise: invest in integration, prioritize trust, and leverage industrial heritage as a launchpad for AI innovation. The question isn’t whether to automate, but how to automate with German-level excellence.