Table of Contents

ToggleUniversal Assembly System: The Future of Flexible, High-Precision Manufacturing

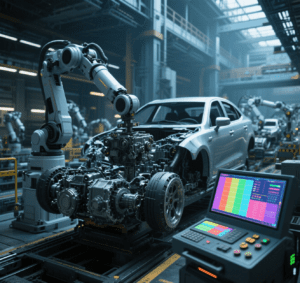

In an era where consumer demands shift rapidly and product customization is king, traditional assembly lines—rigid, slow to reconfigure, and limited to single-product production—are no longer viable. Manufacturers face the challenge of assembling thousands of SKUs with varying complexities, from tiny smartphone components to large automotive sub-assemblies, while maintaining speed and precision. Enter the Système d'assemblage universel—a revolutionary solution designed to break free from these constraints. By integrating advanced robotics, adaptive tooling, and intelligent software, this system transforms assembly into a dynamic, scalable, and future-proof process.

The Need for Universality: Why Traditional Systems Fall Short

Traditional assembly lines excel at mass-producing identical products but fail miserably in today’s high-mix, low-volume landscape:

- Rigid Fixturing: Changing from one product to another requires days of retooling, costing millions in downtime.

- Limited Dexterity: Conveyor-based systems struggle with complex 3D assemblies, relying on manual intervention for angled or asymmetric parts.

- Quality Variability: Human operators introduce inconsistencies, especially for micron-level tasks like aligning camera modules or pressing precision bearings.

The Universal Assembly System addresses these pain points with a foundation of flexibility, precision, and intelligence, enabling manufacturers to assemble virtually any product with minimal setup.

Core Technologies: The Building Blocks of Universality

1. Multi-Axis Robotic Arms: Dexterity for Any Task

At the heart of the system are 6-axis collaborative robots (cobots) and SCARA robots, working in tandem to handle both delicate and heavy-duty tasks:

- 6-Axis Cobots: Offer 6 degrees of freedom (6DOF) for complex orientations, such as inserting a 45° angled connector into a circuit board with ±0.1° accuracy.

- SCARA Robots: Excel at high-speed planar motion, achieving pick-and-place cycles of 0.3 seconds for tiny components (e.g., 0201 SMD resistors).

- Hybrid Configuration: Combines the strengths of both robot types in a single workcell, allowing seamless switching between 3D assembly and high-speed 2D tasks.

2. Modular End-of-Arm Tooling (EOAT): One System, Endless Tools

Quick-release tooling lets the system adapt to 1000+ part types in <5 minutes:

- Adaptive Grippers: Soft robotic fingers conform to irregular shapes (e.g., curved plastic housings or textured metal brackets), applying 0.5–50N of force.

- Vision-Guided Tools: Vacuum nozzles with integrated cameras ensure precise pickup of reflective or transparent parts (e.g., OLED panels or glass lenses).

- Tool Library: Stores digital twins of every gripper, the system auto-calibrates when a new tool is attached, eliminating manual programming.

3. AI-Powered Vision and Sensing: Seeing, Thinking, Acting

A 3D vision system with deep-learning algorithms acts as the system’s “brain”:

- Chaotic Part Recognition: Identifies randomly oriented components in bins with 99.9% accuracy, even for parts with subtle differences (e.g., left vs. right automotive brackets).

- Real-Time Error Correction: Detects assembly deviations (e.g., a 0.2mm misalignment in a smartphone camera module) and adjusts robot motion mid-task.

- Defect Inspection: Scans parts for scratches, missing features, or dimensional errors before assembly, reducing downstream failures by 95%.

4. Smart Software: Orchestrating Complexity

The system’s software ecosystem ties everything together:

- No-Code Programming: Drag-and-drop interfaces let engineers design new assembly sequences in hours, not weeks.

- AI Path Optimization: Machine learning algorithms continuously refine robot trajectories, reducing cycle times by 15–20% over time.

- IoT Integration: Feeds real-time data (cycle times, tool wear, defect rates) to MES systems for predictive maintenance and production scheduling.

Applications: From Micro to Macro, Any Product, Anytime

1. Consumer Electronics: High-Mix, High-Precision Assembly

In a smartphone factory producing 20+ models with varying camera modules:

- The system switches from assembling a flagship phone’s triple-lens module (requiring 0.03mm alignment) to a budget model’s single-lens setup in 10 minutes.

- Vision-guided cobots insert flex cables into tight connectors with 99.8% first-pass success, compared to 85% for manual assembly.

Result: A leading OEM reduces new product ramp-up time by 40%, launching 50+ models annually with zero assembly line overhauls.

2. Automotive: Complex Sub-Assembly with Heavy Parts

For a tier-1 supplier assembling electric vehicle (EV) motor controllers:

- Robust 6-axis robots handle 15kg aluminum housings, while SCARA arms place 0.5mm-thick thermal pads with ±0.1mm precision.

- Force-torque sensors ensure bolts are tightened to 10±0.5N·m, eliminating over-tightening defects that cause short circuits.

Case Study: The system processes 500+ motor controllers daily across 10 vehicle platforms, with a 70% reduction in labor costs.

3. Medical Devices: Sterile, Precision-Critical Assembly

In a pharmaceutical plant manufacturing insulin pens:

- Sterile-grade grippers and vision systems handle 2mm-diameter plastic pistons, ensuring no particulates contaminate the assembly.

- Automated torque control inserts needles with 0.05mm depth accuracy, meeting ISO 13485 compliance effortlessly.

Universal Assembly System vs. Traditional Lines: A Paradigm Shift

| Metric | Universal System | Traditional Assembly Line |

| Product Changeover Time | <30 minutes | 8–48 hours |

| Part Types Supported | 1000+ (software-defined) | 1–5 (hardware-dependent) |

| Positioning Accuracy | ±0.02mm (micron-level) | ±0.5mm (operator-dependent) |

| Labor Requirement | 1–2 operators per line | 10–20 operators |

| Scrap Rate | <0.5% | 5–10% |

The Business Case: Investing in Agility

1. Rapid ROI Through Flexibility

- Downtime Reduction: 90% less changeover time means factories can run 3x more product variants without adding lines.

- Labor Savings: Replaces 80% of manual assembly tasks, saving $200k–$500k annually per line (depending on region).

- Quality Assurance: Consistent precision reduces rework costs by 60%, critical for industries like aerospace where a single defect can cost millions.

2. Future-Proofing for Industry 4.0

- Mass Customization: Effortlessly handles lot sizes from 1 to 10,000, enabling “batch size 1” production for personalized products.

- Scalability: Modular design allows easy expansion—add a robot, tool, or workcell without disrupting existing operations.

- Data-Driven Insights: Real-time analytics identify bottlenecks and optimize workflows, paving the way for fully autonomous factories.

The Future of Assembly: Where Versatility Meets Intelligence

As manufacturing evolves toward greater customization and complexity, the Universal Assembly System leads the charge with innovations like:

- Self-Learning Algorithms: Continuously improve assembly strategies using real-world data, achieving 10–15% faster cycle times after 3 months of operation.

- Zero-Programming Onboarding: AI automatically generates assembly recipes by analyzing part CAD models, reducing new product setup from days to hours.

- Sustainable Design: Energy-efficient robots and minimal material waste align with global ESG goals, reducing carbon footprints by 30% compared to traditional lines.

In a world where “one size fits all” is obsolete, the Universal Assembly System is not just a tool—it’s a revolution. It empowers manufacturers to embrace the future of production: a world where any product, no matter how complex or unique, can be assembled with speed, precision, and unmatched efficiency.

#Système d'assemblage universel #Modular Robotics Automation #Smart Factory Solutions