As a core product in cosmetics, pharmaceuticals, and daily chemical industries, vacuum bottles have strict requirements for assembly precision, airtightness, and production flexibility. Traditional manual assembly and single-function equipment suffer from low efficiency, unstable quality, and poor adaptability to multiple specifications. Ruizhi Intelligent Manufacturing’s top-rated vacuum bottle assembly machine integrates automation, precision control, and customization, creating a high-performance production solution for global manufacturers.

All-in-One Production Efficiency

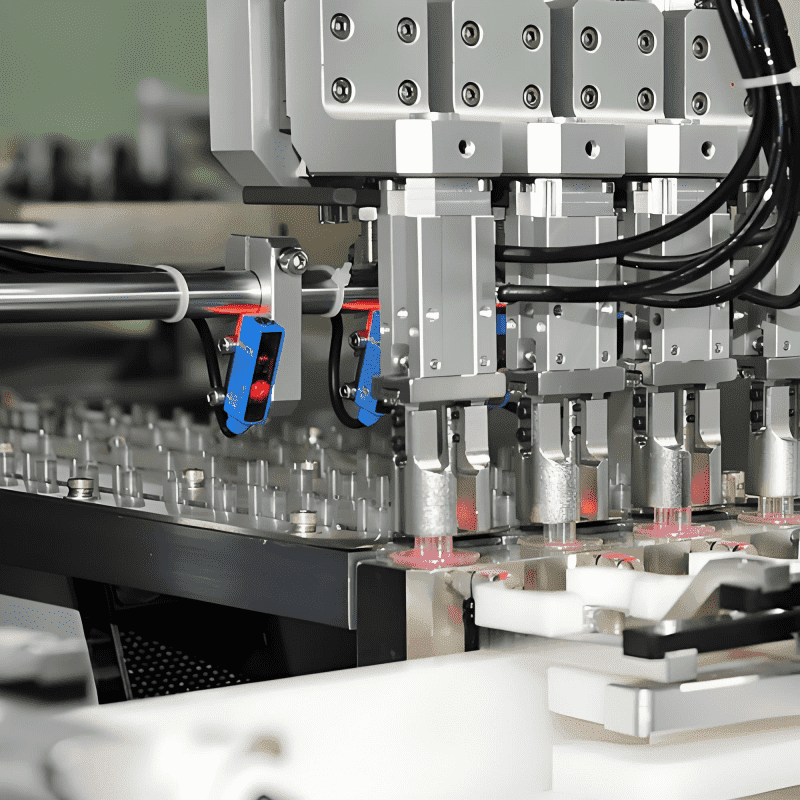

Our machine integrates core processes including bottle body feeding, piston pressing, burr removal, airtightness testing, and finished product sorting, eliminating discrete manual operations and process handovers. Equipped with servo motors and PLC control systems, it achieves a production capacity of 1000-1500 bottles per hour, 5-7 times that of manual assembly.

The integrated design also realizes synchronous burr cleaning inside the bottle during assembly, avoiding air leakage and piston jamming caused by residual impurities. Only one operator is needed for overall supervision, reducing labor costs by over 80% while ensuring continuous 24-hour stable operation.

Adapt to Diverse Specifications

As a professional non-standard automation manufacturer, Ruizhi excels in tailoring solutions for diverse vacuum bottle types. The machine features adjustable clamping fixtures and modular components, flexibly adapting to vacuum bottles of different diameters (35-110mm), heights (50-180mm), and materials (glass, plastic).

The parameter memory function shortens product changeover time to within 5 minutes, efficiently meeting small-batch and multi-specification production needs. Whether for cosmetic emulsion bottles or medical vacuum containers, we provide customized process optimization to match specific production requirements.

Strict Quality Control

Adopting AI visual positioning technology, the machine achieves assembly precision within ±0.03mm, ensuring tight fitting of pistons and bottle necks. The built-in automatic airtightness testing unit detects each product with negative pressure, automatically sorting out unqualified products with air leakage.

Key components are made of 304 stainless steel, complying with food and pharmaceutical industry hygiene standards. This rigorous quality control pushes the finished product qualification rate to over 99.8%, safeguarding brand reputation.

Ruizhi Intelligent Manufacturing’s vacuum bottle assembly machine combines efficiency, flexibility, and precision, helping enterprises gain an edge in the competitive market. We also provide one-stop services from on-site commissioning to after-sales maintenance.