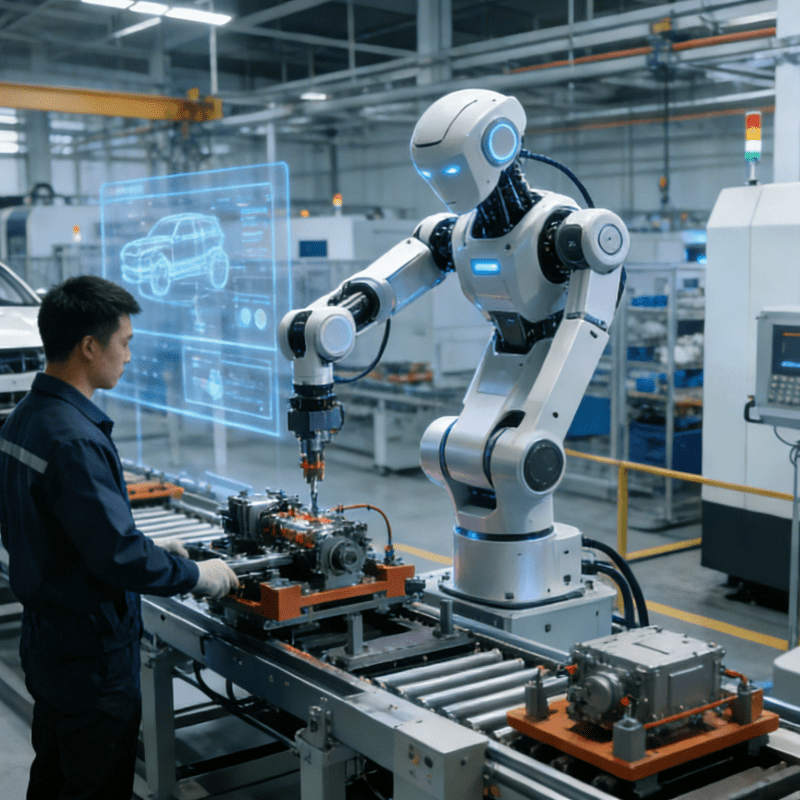

In the wave of global manufacturing automation, even small components like sealing rings—critical for waterproofing, pressure retention, and leak prevention in equipment—are undergoing a transformation from manual assembly to intelligent automation. As a core link in the production chain of automobiles, home appliances, hydraulic systems, and medical devices, sealing ring assembly has long been plagued by low efficiency, high error rates, and unstable quality in manual operations. Today, the Automatic Sealing Ring Feeding And Assembly System is emerging as a “sealing guardian,” solving these pain points and becoming a key driver for enterprises to improve production efficiency and product reliability.

Why Manual Assembly of Sealing Rings Is Being Phased Out

Sealing rings, though small, play a decisive role in product performance. A misaligned or deformed sealing ring can lead to equipment leaks, reduced service life, or even safety hazards—for example, a faulty sealing ring in an automobile engine could cause oil leakage, triggering engine failure. However, traditional manual assembly faces inherent limitations:

Low efficiency: A skilled worker can only assemble 8–12 sealing rings per minute, and fatigue leads to a sharp drop in speed during long shifts.

High error rates: Manual judgment of sealing ring orientation (e.g., inner/outer diameter, chamfer direction) and assembly pressure often results in misalignment or over-compression, with defect rates as high as 3–5%.

Unstable quality: Human factors such as hand oil, improper force application, or negligence can damage the sealing ring’s surface, affecting its sealing performance.

Against this backdrop, the automatic sealing ring feeding and assembly system has become an inevitable choice for manufacturing enterprises pursuing “high efficiency, high precision, and low cost.”

Core Principles: How the Automatic System Achieves “Precision Without Error”

A mature automatic sealing ring feeding and assembly system integrates material sorting, precise conveying, intelligent assembly, and real-time detection into a closed-loop workflow. Its core modules work in synergy to ensure every sealing ring is assembled accurately and reliably:

- Feeding Unit: “Orderly Arrangement” of Chaotic Sealing Rings

The feeding unit is the starting point of the system, mainly relying on vibration discs and visual sorting modules to solve the problem of “disordered material organization”:

Vibration discs: Through high-frequency, low-amplitude vibration, sealing rings (often mixed in bulk) are guided along a spiral track. The track’s design (e.g., width matching the sealing ring’s thickness, notches for orientation correction) ensures that only correctly oriented sealing rings (e.g., chamfer facing upward) enter the next link, while misoriented ones are pushed back into the material pool for re-sorting.

Visual verification: For special-shaped sealing rings (e.g., square, oval) or those with logos/markings, a high-resolution industrial camera (12–20 megapixels) captures images, and AI algorithms quickly identify orientation and surface defects (e.g., cracks, burrs), further improving the quality of incoming materials.

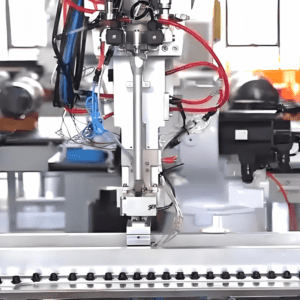

- Conveying Unit: “Silent Delivery” to the Assembly Station

After sorting, the sealing rings are conveyed to the assembly station via precision conveyors or lightweight robotic arms:

Precision conveyors: Equipped with servo motors and position encoders, they control the conveying speed (adjustable from 0.5–2 m/s) to match the assembly rhythm, ensuring no jamming or collision between sealing rings.

Robotic arms: For multi-station assembly lines (e.g., automobile gearbox production), 4-axis or 6-axis robotic arms with vacuum suction cups or mechanical grippers pick up sealing rings, achieving flexible transfer between different stations with a positioning accuracy of ±0.02 mm.

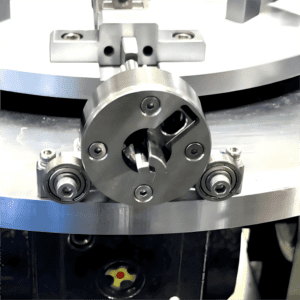

- Assembly Unit: “Controlled Force” for Precise Installation

The assembly unit is the core of the system, focusing on positioning accuracy and assembly force control:

Positioning technology: Laser displacement sensors or machine vision systems locate the assembly hole (e.g., on a washing machine water pump) with an accuracy of up to ±0.01 mm, ensuring the sealing ring is aligned with the hole’s center.

Force control: Servo presses or torque sensors monitor the assembly force in real time (e.g., 50–200 N for rubber sealing rings). If the force exceeds the threshold (indicating jamming) or is too low (indicating incomplete assembly), the system immediately stops and alarms, avoiding damage to the sealing ring or the workpiece.

- Detection Unit: “Final Check” to Eliminate Defects

After assembly, the system conducts two rounds of detection to ensure zero defects:

Visual detection: Cameras check whether the sealing ring is fully seated, whether there are gaps, and whether its surface is intact.

Pressure/leakage detection: For key application scenarios (e.g., hydraulic cylinders), the system performs a pressure test (e.g., 0.5–1 MPa) on the assembled workpiece, verifying that the sealing ring meets the leak-proof requirements.

Only workpieces that pass both tests enter the next production link; defective ones are automatically sorted into waste bins, and the system records the defect type for subsequent process optimization.

Typical Application Scenarios: From Automobiles to Medical Devices

The automatic sealing ring feeding and assembly system’s flexibility and adaptability make it suitable for multiple industries, addressing the unique needs of different scenarios:

- Automotive Industry: High Beat, High Reliability

In automobile engine and transmission production, sealing rings are used in oil pans, valve covers, and hydraulic control units. The system needs to match the assembly line’s high beat (e.g., 30–40 workpieces per minute). For example, a domestic automobile engine factory introduced an automatic system, increasing the sealing ring assembly efficiency by 300% compared to manual operations, and reducing the defect rate from 4.2% to 0.08%.

- Home Appliance Industry: Small Batch, Multi-Specification

Washing machines, air conditioners, and water heaters use sealing rings of different sizes (e.g., 20–100 mm inner diameter) and materials (e.g., EPDM, silicone). The system’s quick-change modules (e.g., replaceable vibration discs, adjustable robotic arm grippers) allow for switching between product models in 10–15 minutes, meeting the home appliance industry’s “multi-variety, small-batch” production needs.

- Medical Device Industry: Ultra-High Precision

In medical equipment such as hemodialysis machines and infusion pumps, sealing rings must meet strict biocompatibility and precision requirements. The system uses piezoelectric ceramic drives for assembly force control (accuracy ±1 N) and sterile-grade conveying components (e.g., 316L stainless steel), ensuring compliance with medical industry standards (e.g., ISO 13485).

Core Advantages: Creating Value for Manufacturing Enterprises

Compared with manual assembly and semi-automatic equipment, the automatic sealing ring feeding and assembly system brings tangible value to enterprises in multiple dimensions.

In terms of efficiency upgrade, the system’s assembly speed reaches 20–40 pieces per minute, which is 2–4 times that of manual operations. More importantly, it supports 24/7 continuous production, completely breaking the efficiency bottlenecks caused by manual shift changes and fatigue. For enterprises with high-volume production demands, this means a direct leap in daily output.

In quality improvement, the system significantly reduces defect rates: from 3–5% in manual assembly to 0.1–0.5%. Its consistent assembly force control ensures that every sealing ring is installed with the same pressure, avoiding problems like over-compression (which damages the sealing ring) or under-compression (which causes leaks), thus stabilizing the overall sealing performance of the final product.

In cost reduction, each production line can save 2–3 manual positions after adopting the system. Considering labor costs, training expenses, and the loss caused by manual errors, the initial investment in the equipment is usually recovered within 1–1.5 years. For small and medium-sized enterprises, this short payback period lowers the threshold for adopting automation.

In data-driven optimization, the system can integrate with manufacturing execution systems (MES) to collect real-time data such as assembly speed, defect types, and equipment operating status. These data provide a basis for enterprises to optimize processes—for example, if the system records frequent “orientation error” defects, technicians can adjust the vibration disc’s track design to reduce such issues.

Challenges and Future Trends

Despite its obvious advantages, the promotion of automatic sealing ring feeding and assembly systems still faces certain challenges. One key issue is non-standard sealing rings: for special-shaped or custom-sized products, enterprises need to customize vibration discs, grippers, and detection parameters, which increases initial investment costs and extends the debugging cycle. Another challenge is maintenance requirements: the system’s precision components (such as servo motors, industrial cameras, and force sensors) need regular calibration and maintenance, which places higher demands on the professional skills of enterprise maintenance teams.

Looking ahead, the technology will develop in three clear directions. The first is flexible intelligence: future AI vision systems will have “self-learning” capabilities—they can automatically recognize sealing rings of different specifications and adjust sorting and assembly parameters without manual intervention, greatly improving the system’s adaptability to multi-variety production. The second is digital twin: by building a virtual model of the assembly system, enterprises can conduct pre-production debugging, fault simulation, and efficiency optimization in the virtual space, reducing downtime caused by on-site debugging and improving equipment utilization. The third is green energy saving: with the rise of low-carbon manufacturing, the system will adopt energy-saving servo motors and low-noise vibration discs, reducing overall energy consumption by 15–20% while meeting environmental protection standards.

Conclusion: A Small Component, A Big Step in Automation

The automatic sealing ring feeding and assembly system may seem like a “small link” in the manufacturing chain, but it embodies the core logic of manufacturing automation—replacing manual operations with precision, efficiency, and stability. As enterprises continue to pursue high-quality development, this system will not only be widely used in traditional industries such as automobiles and home appliances but also play a key role in emerging fields such as new energy vehicles and industrial robots.

In the future, with the integration of more intelligent technologies, the automatic sealing ring feeding and assembly system will become more flexible, cost-effective, and environmentally friendly. It will no longer be just a “tool” for replacing manual labor, but a “smart partner” that helps the manufacturing industry take a solid step toward “intelligent manufacturing.”