In automotive interiors, 3C electronics, smart homes, and other fields, fasteners (snap-fit connectors) serve as low-cost, easy-to-operate connecting components that provide core functions such as structural fixation and part assembly. From tiny phone case fasteners to heavy-duty automotive door panel fasteners, applications span from precision electronics to heavy industry.

However, traditional manual fastener assembly has long suffered from low efficiency, poor precision, and inconsistent quality. In one washing machine panel assembly line, workers could only produce 600 units per person per day with a defect rate of 2.8%, requiring additional quality inspection personnel to address issues like missing or reversed installations.

As manufacturing transitions toward flexibility and intelligence, automatic fastener feeding and assembly systems have emerged as the key solution to these bottlenecks.

Core Components of Automatic Fastener Systems: From “Discrete Operations” to “Closed-Loop Collaboration”

A complete system consists of five core units working together to automate the entire process from “disordered pile” to “precision assembly”:

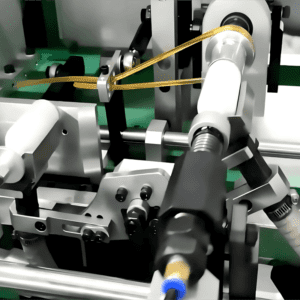

- Flexible Feeding Unit: Overcoming “Irregular Fastener” Challenges

The feeding unit faces the challenge of accommodating fasteners of different materials (plastic, metal) and structures (barbed, multi-claw, cylindrical). The new generation system uses a combination approach:

Customized guide grooves in the vibratory bowl prevent jamming

Elastic buffers added for barbed automotive fasteners

Industrial camera at the end of the track identifies and rejects improper ones

Quick-change capability allows switching between fastener types in 15 minutes

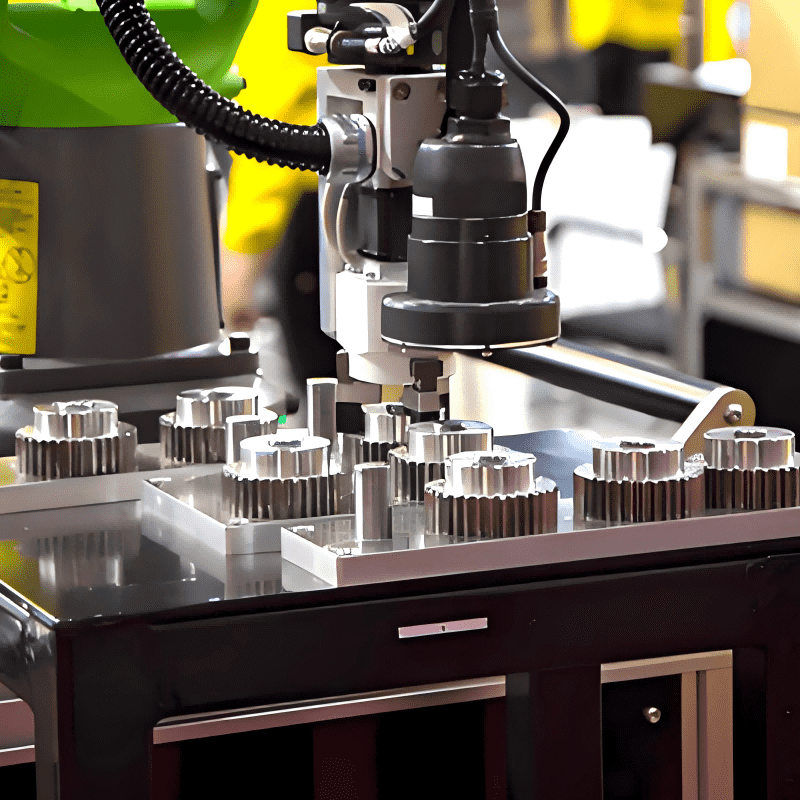

- Vision Positioning and Gripping Unit: The “Smart Hand” with Millimeter Precision

Precision is critical, especially in 3C electronics where gaps must be within 0.05mm:

High-resolution cameras (≥20MP) locate reference points and calculate deviations

Six-axis collaborative robots use vacuum suction cups or custom grippers

Error compensation algorithms ensure assembly accuracy within ±0.02mm

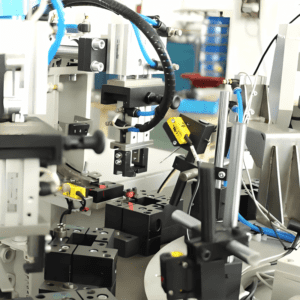

- Assembly Execution and Inspection Unit: From “Assembly Completed” to “Quality Confirmed”

The assembly unit uses force control for different fastener types:

Stops automatically when preset force thresholds are reached

Dual verification ensures quality:

Vision inspection checks for missing, misaligned, or deformed fasteners

Pull-test verifies strength (≥50N for automotive applications)

Defective products automatically rejected with reasons recorded in MES

- Central Control System: The “Brain” of the Entire Process

PLC + HMI architecture supports MES/ERP integration:

Operators set parameters and monitor performance in real-time

Automatic alerts for jams or malfunctions with troubleshooting guidance

Mean time to repair reduced from 30 to 8 minutes

Key Technological Breakthroughs

- “Adaptive Adjustment” for Multiple Specifications

Through parameter configuration and modular design:

System automatically recalls settings for different fastener types

No mechanical adjustments needed between product changes

Equipment utilization increased from 65% to 88%

- Dynamic Error Compensation

Addresses workpiece deformation issues:

Vision system captures images every 0.5 seconds

Robot adjusts coordinates in real-time for up to 0.2mm deformation

Defect rate reduced from 1.9% to 0.3% in automotive applications

- Full-Process Data Traceability

Creates a “one item, one code”:

RFID or QR code tracks each fastener’s assembly data

Quickly identifies specific batches and equipment when issues arise

Data-driven optimization reduces defects by 0.5% in humidity-sensitive cases

Industry Applications

- Automotive Industry: Reliable Heavy-Duty Fastener Assembly

After implementing the system:

Production increased from 800 to 3,200 units/day

Zero after-sales issues related to fastener looseness in 12 months

- 3C Electronics: Precision Micro-Fastener Assembly

With dual-vision guidance:

Completes 1,200 fasteners/hour with defect rate reduced to 0.15%

Saves 6 operators, cutting labor costs by about RMB 480,000/year

- Smart Home Industry: Batch Production Efficiency

Multi-station parallel line:

Four robots share one feeding system

Capacity reaches 4,000 units/hour (5x manual efficiency)

System scales production according to order demand

Challenges and Future Trends

Despite widespread adoption, challenges remain with irregular shapes, oily metal surfaces, and high-elasticity fasteners. Future developments include:

- AI-Driven Predictive Maintenance

Sensor data combined with AI predicts potential failures

Guides preventive maintenance actions

Reduces equipment failure rate by 40% and maintenance costs by 30%

- Digital Twin Virtual Debugging

Simulates entire process in virtual environment

Optimizes parameters before physical implementation

Reduces debugging from 7 days to 2 days

- Cross-Process Collaborative Automation

Seamless connection with upstream injection molding and downstream testing

Eliminates manual material handling

Increases overall line efficiency by 25%

Conclusion

Automatic fastener feeding and assembly systems represent the transformation from “extensive production” to “precision manufacturing.” They not only free workers from repetitive tasks but also improve product reliability through data-driven processes. As technology advances, these systems will find applications in increasingly specialized fields, injecting new momentum into the intelligent upgrading of manufacturing.

Would you like me to highlight any specific aspect of this technology for a particular industry application?