In the wave of global manufacturing transformation, hardware parts—such as screws, nuts, buckles, and terminals—are the “building blocks” of almost all industrial products. However, the traditional manual feeding and assembly of hardware parts have long been plagued by low efficiency, high error rates, and heavy labor dependence, becoming a bottleneck restricting the production rhythm of enterprises. Against this backdrop, Automatic Hardware Part Feeding And Assembly technology has emerged as a key solution to break through this bottleneck, integrating precision machinery, intelligent sensing, and automated control to reshape the production mode of the hardware manufacturing industry.

- The Technical Logic of Automatic Hardware Part Feeding And Assembly: From “Precision Delivery” to “Intelligent Assembly”

Automatic hardware part feeding and assembly is not a single device, but a systematic solution that integrates “feeding-sorting-positioning-assembly-detection” into a closed loop. Its core lies in realizing the full-process automation of hardware parts from storage to final assembly, while ensuring high precision and stability.

1.1 Feeding System: The “First Link” of Automation

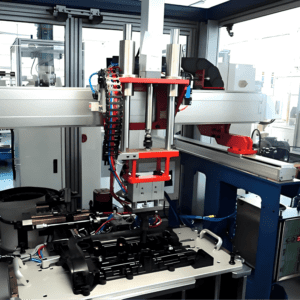

The feeding system is responsible for transferring hardware parts from the storage bin to the assembly station in an orderly manner, and its performance directly determines the efficiency of the entire assembly line. Currently, three types of feeding technologies are widely used in the industry:

Vibratory Bowl Feeder: The most mature and widely used technology, suitable for small and medium-sized standard hardware parts (such as M2-M8 screws, small buckles). It uses electromagnetic vibration to drive the parts to climb along the spiral track; during the climbing process, the sorting mechanism (such as notches, baffle plates, and orientation pins) screens out parts with incorrect postures, ensuring that only parts in the “assembly-ready” state enter the next process. For example, in the assembly of automotive connectors, a vibratory bowl feeder can sort 500-1200 terminals per minute, with a posture accuracy rate of over 99.5%.

Belt Conveyor Feeding: Suitable for large or irregular hardware parts (such as long bolts,brackets) that are not easy to be sorted by vibration. It is equipped with photoelectric sensors and positioning cylinders to control the conveying speed and stop position of parts, ensuring that each part is accurately delivered to the grabbing range of the assembly robot. In the production of household appliances, belt conveyors are often used to feed large hinge parts, with a single feeding cycle as short as 3 seconds.

Robot-Assisted Feeding: For high-value, complex-shaped hardware parts (such as precision gears, medical hardware), industrial robots (equipped with vision sensors) are used for “targeted grabbing”. The 3D vision system can identify the position and posture of parts in the material box in real time, and guide the robot to adjust the grabbing angle, avoiding damage to parts and ensuring feeding flexibility. This technology is widely used in the assembly of aerospace hardware, with a grabbing accuracy of up to ±0.005mm.

1.2 Assembly System: The “Core Execution” of Precision

After the parts are accurately fed, the assembly system completes the connection, fastening, or fitting of hardware parts according to the process requirements. Its core lies in “precision control”—not only to ensure the accuracy of assembly position, but also to avoid damage to parts due to excessive force.

Positioning Technology: Visual positioning is the mainstream solution. The industrial camera captures the image of the assembly base and the hardware part, and the algorithm calculates the deviation between the actual position and the theoretical position, then sends a correction signal to the motion controller. For example, in the assembly of mobile phone middle frames and metal buckles, visual positioning can control the assembly deviation within ±0.01mm, ensuring that the buckle can be smoothly engaged without looseness.

Connection Technology: According to the type of hardware parts, different automatic connection methods are adopted: for screws, automatic screw-locking machines with torque control (torque accuracy ±5%) are used to avoid over-tightening or under-tightening; for rivets, pneumatic riveting machines with pressure feedback are used to ensure that the riveting depth meets the standard; for snap-fit parts, servo-driven pressing heads are used to control the pressing speed and force, preventing the buckle from being broken due to sudden force.

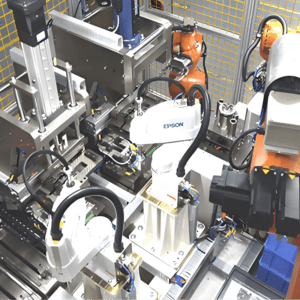

Collaborative Assembly: In complex scenarios (such as the assembly of automobile engine cylinder heads, which involves dozens of bolts), multi-robot collaboration is adopted. One robot is responsible for feeding bolts, another for positioning the bolt holes, and the third for locking the screws. The motion controller uniformly coordinates the actions of multiple robots to avoid interference, and the assembly efficiency is 3-5 times that of manual work.

- Application Scenarios: Penetrating All Fields of Manufacturing

Automatic hardware part feeding and assembly technology has strong adaptability, and its application scenarios have expanded from traditional machinery manufacturing to emerging fields such as automobiles, electronics, and medical care, becoming an indispensable part of intelligent production lines.

2.1 Automotive Industry: High-Volume, High-Stability Demand

The automotive industry is the largest application market for automatic hardware assembly. A single car contains thousands of hardware parts, and the assembly requires high consistency. For example:

In the assembly of automotive door modules, automatic feeding systems deliver screws, buckles, and hinges to the assembly station in sequence; SCARA robots (horizontal multi-joint robots) complete the screw locking and buckle pressing, with a cycle time of only 20 seconds per door module, and the defect rate is controlled below 0.05% (far lower than the 1-2% of manual assembly).

In the production of new energy vehicle batteries, automatic feeding and assembly systems are used to install the metal terminals of battery packs. The force-controlled assembly technology ensures that the terminal pressing force is stable at 500±10N, avoiding poor contact caused by insufficient force or terminal deformation caused by excessive force.

2.2 Electronic Industry: Precision-Oriented, Small-Batch Diversification

The electronic industry has strict requirements for the precision of hardware assembly, and the product models are updated quickly, requiring the feeding and assembly system to have strong flexibility. For example:

In the assembly of smart watches, the automatic system feeds tiny screws (M1.0-M1.2) and metal brackets; the six-axis collaborative robot, equipped with a micro-force sensor, completes the screw locking with a torque of only 0.05N·m, ensuring that the watch case is not deformed and the screws are not stripped.

In the production of 5G base station antennas, the automatic system can quickly switch between feeding different specifications of metal connectors (by replacing the vibratory bowl track and calling pre-stored parameters), adapting to the small-batch, multi-variety production needs of antennas, and the model switching time is shortened from 2 hours (manual) to 15 minutes.

2.3 Medical Device Industry: High-Standard, Sterile Requirements

Medical devices (such as surgical forceps, infusion pumps) have extremely high requirements for the quality and sterility of hardware parts. The automatic feeding and assembly system needs to meet the GMP (Good Manufacturing Practice) standards:

The equipment is made of stainless steel (316L) that is easy to clean and disinfect; the feeding channel is designed with no dead corners to avoid material residue and bacterial growth.

In the assembly of infusion pump check valves, the automatic system uses a vision inspection system to detect the surface defects of the valve core (such as burrs, scratches) before feeding, and uses a pressure test module to detect the sealing performance of the assembly after assembly, ensuring that each product meets the medical safety standards.

- Core Advantages: Why Automatic Hardware Feeding And Assembly Becomes a “Must-Have” for Enterprises

Compared with traditional manual operations, automatic hardware part feeding and assembly technology brings multi-dimensional improvements to enterprises, not only improving production efficiency, but also enhancing product quality and reducing comprehensive costs.

3.1 Efficiency Leap: Breaking Through the “Human Speed Limit”

Manual assembly of hardware parts is limited by physical strength and concentration, and the efficiency is difficult to maintain stably. For example, a worker can assemble about 80-100 hardware components per hour, while an automatic assembly line can complete 300-800 components per hour, with an efficiency increase of 3-5 times. Moreover, the automatic system can operate 24 hours a day without fatigue, significantly increasing the daily output of enterprises.

3.2 Quality Upgrade: Reducing Errors Caused by Human Factors

Manual assembly is prone to errors such as incorrect part posture, improper fastening torque, and missing assembly, which directly affect product performance. The automatic system relies on precise sensing and control technology to ensure that each assembly step meets the process standards: the visual positioning system reduces position errors, the torque/force control system avoids over-tightening/under-tightening, and the online detection system prevents missing assembly. Taking the automotive fastener assembly as an example, the defect rate of automatic assembly is less than 0.1%, while the manual defect rate is usually 2-3%.

3.3 Cost Reduction: Balancing Short-Term Investment and Long-Term Returns

Although the initial investment in automatic hardware feeding and assembly systems is higher than that of manual lines, enterprises can achieve cost recovery within 1-2 years through long-term savings:

Labor cost: A medium-sized automatic assembly line can replace 3-5 manual workers, saving annual labor costs of 300,000-800,000 yuan (depending on the region and salary level).

Material cost: The automatic system reduces the scrap rate of hardware parts (from 5% manual to 0.5% automatic), and the annual material savings can reach hundreds of thousands of yuan for enterprises with large production volumes.

Management cost: The automatic system can be connected to the MES (Manufacturing Execution System) to realize real-time monitoring of production data (output, defect rate, equipment status), reducing the workload of on-site management and improving management efficiency.

3.4 Safety Enhancement: Reducing Workplace Accidents

Manual handling of hardware parts (especially heavy or sharp parts) is prone to workplace accidents such as hand cuts and back injuries. The automatic system realizes “unmanned operation” in the feeding and assembly links, and workers only need to monitor the equipment status in the control room, fundamentally avoiding direct contact with dangerous parts. According to statistics from the International Labour Organization, enterprises that adopt automatic hardware assembly systems have a 60% lower rate of hardware-related workplace accidents.

- Challenges and Future Trends: Toward More Intelligent and Flexible Development

While automatic hardware part feeding and assembly technology has achieved remarkable results, it still faces some challenges in practical application: for example, the feeding efficiency of irregularly shaped hardware parts is low (easy to get stuck), the debugging cycle of multi-variety production is long, and the maintenance cost of high-precision equipment is high. To solve these problems, the technology is moving toward three major trends:

4.1 AI-Driven Intelligent Optimization

AI technology will be deeply integrated into the feeding and assembly system:

Predictive Maintenance: Sensors collect data such as vibration, temperature, and current of the feeding machine and assembly robot; the AI model analyzes the data to predict potential faults (such as bearing wear, sensor deviation) and send early warnings, reducing unplanned downtime by 30-50%.

Adaptive Feeding: For irregular parts, the AI vision system can learn the shape characteristics of different parts, automatically adjust the vibration frequency of the vibratory bowl or the grabbing angle of the robot, and improve the feeding success rate from 85% to over 98%.

4.2 Digital Twin-Enabled Virtual Debugging

The digital twin technology will build a “virtual replica” of the automatic feeding and assembly line. Before the actual production, enterprises can simulate the feeding process, assembly sequence, and equipment collaboration in the virtual environment, optimize parameters (such as vibration speed, robot movement path) and eliminate potential conflicts. This can shorten the debugging cycle of the new production line from 1 month to 1-2 weeks, and reduce the debugging cost by 40%.

4.3 Green and Low-Carbon Design

With the global emphasis on environmental protection, automatic hardware feeding and assembly systems will pay more attention to energy conservation and emission reduction:

Energy-Saving Components: Use servo motors with high energy efficiency (IE4 level) instead of traditional asynchronous motors, reducing energy consumption by 20-30%; use LED lighting in the visual detection system to save electricity.

Noise Reduction: Add sound insulation covers to vibratory bowls and use silent cylinders in the assembly mechanism, reducing the noise of the production line from 80dB to below 65dB, improving the working environment of workers.

Conclusion: Automatic Hardware Part Feeding And Assembly—The Cornerstone of Intelligent Manufacturing

Automatic hardware part feeding and assembly technology is not only a tool to improve production efficiency, but also a key link in promoting the transformation of manufacturing from “labor-intensive” to “technology-intensive”. With the continuous iteration of precision machinery, intelligent sensing, and AI algorithms, this technology will become more flexible, precise, and green, and penetrate into more fields (such as aerospace, marine engineering). For enterprises, mastering automatic hardware feeding and assembly technology is not only a way to gain competitive advantages, but also a necessary path to adapt to the global manufacturing transformation. In the future, as the technology matures and costs decrease, it will become the “standard configuration” of intelligent production lines, helping the manufacturing industry move toward a higher quality, more efficient, and more sustainable development future.