Table of Contents

ToggleRevolution on the Factory Floor: How Automation is Redefining the Future of Manufacturing

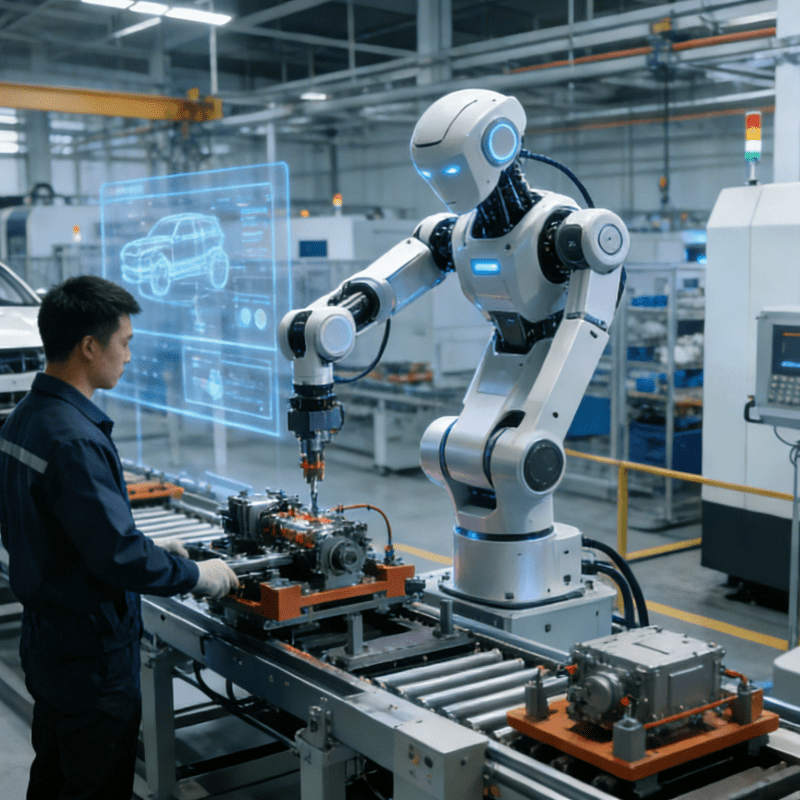

Revised Opening: The Triumvirate of Automation Technologies

The factory floor is undergoing a seismic shift, driven by the convergence of automatisation intelligente, automatisation industrielle, and cutting-edge équipement d'automatisation. From the first steam-powered mills of the Industrial Revolution to today’s AI-driven smart factories, automation has consistently rewritten the rules of productivity, quality, and scalability. Now, as Industry 4.0 accelerates, these three pillars—automatisation intelligente (AI and machine learning), automatisation industrielle (robotics and process integration), and équipement d'automatisation (sensors, cobots, and IoT devices)—are merging to create a manufacturing ecosystem that’s faster, smarter, and more adaptive than ever before.

The Evolution of Manufacturing Automation: A Journey Through Eras

Manufacturing automation has unfolded in distinct phases, each propelled by breakthroughs in automatisation industrielle et équipement d'automatisation:

Mechanization (1st Industrial Revolution):

The shift from manual labor to water/steam-powered équipement d'automatisation (e.g., spinning jenny, steam engines) marked the dawn of industrial production. Factories replaced workshops, with automatisation industrielle in its nascent form reducing reliance on human and animal labor.

Mass Production (2nd Industrial Revolution):

Henry Ford’s assembly lines epitomized automatisation industrielle, using conveyor belts and standardized équipement d'automatisation (e.g., electric-powered machines) to produce the Model T at scale. This era solidified automation’s role in driving efficiency and lowering costs.

Digital Automation (3rd Industrial Revolution):

The rise of computers and PLCs introduced programmable équipement d'automatisation, enabling precise control over repetitive tasks. Robotics emerged as a cornerstone of automatisation industrielle, with machines like the Unimate robot enhancing accuracy in automotive assembly.

Smart Manufacturing (Industry 4.0):

Today, automatisation intelligente—powered by AI, IoT, and cyber-physical systems—has elevated automatisation industrielle to new heights. Automation equipment now includes self-diagnosing machines, collaborative robots (cobots), and AI-driven quality control systems, creating factories that learn, adapt, and optimize in real time.

Key Technologies: The Trifecta of Modern Automation

Intelligent Automation (AI & Machine Learning):

AI analyzes vast datasets to predict equipment failures, optimize supply chains, and even design products. For example, predictive maintenance powered by AI reduces downtime by 30%, while machine learning algorithms detect defects with 99% accuracy in quality control systems.

Advanced Robotics (Industrial Automation):

Modern robots, from BMW’s humanoid cobots to Xiaomi’s smartphone-assembling machines, embody automatisation industrielle at its peak. These équipement d'automatisation marvels can place parts with micron-level precision and work 24/7, boosting output by 400% in some cases.

IoT and Connected Systems (Automation Equipment):

IoT-enabled équipement d'automatisation—sensors, actuators, and smart devices—creates a “digital twin” of the factory floor. Real-time data on machine performance, energy usage, and inventory levels allows manufacturers to fine-tune processes and reduce waste by up to 20%.

Impact on Manufacturing: Where Automation Shines

- Predictive Maintenance: AI-driven équipement d'automatisationlike vibration sensors and thermal cameras predict failures before they occur, minimizing downtime and extending machine lifespan.

- Customization at Scale: Intelligent automationenables quick shifts between product lines, allowing brands like Nike to produce customized sneakers in hours rather than days.

- Supply Chain Resilience: During the COVID-19 pandemic, factories using automatisation industrielleand IoT-based équipement d'automatisation adapted faster to disruptions, maintaining production while manual lines stalled.

Case Studies: Automation in Action

- Xiaomi’s Dark Factory: Fully automated automatisation industriellesystems—robots, AI, and équipement d'automatisation—produce one smartphone per second, with zero human intervention.

- BMW’s Humanoid Robots: Partnering with Figure Robotics, BMW deploys cobots that mimic human movements, enhancing flexibility in assembly lines and reducing ergonomic risks for workers.

- Cellares’ Cell Shuttle: In biotech, this équipement d'automatisationrevolutionizes cell therapy production, using robotics to streamline processes and make life-saving treatments more accessible.

Challenges: Balancing Progress and People

While automatisation intelligente et automatisation industrielle drive efficiency, they also raise challenges:

- Workforce Transformation: Routine jobs are being replaced by équipement d'automatisation, requiring upskilling in areas like robotics maintenance and data analysis.

- Cybersecurity Risks: Connected équipement d'automatisationis vulnerable to hacking, necessitating robust security protocols to protect intellectual property and operational integrity.

- Cost Barriers: Small manufacturers often struggle to invest in advanced équipement d'automatisation, though scalable solutions like modular robotics and cloud-based AI are leveling the playing field.

Revised Closing: The Automated Future—Collaboration, Not Replacement

The factory of tomorrow will be a symphony of automatisation intelligente, automatisation industrielle, and human expertise. Automation equipment will handle the repetitive, dangerous, and precise tasks, while humans focus on innovation, problem-solving, and oversight. As seen in BMW’s cobot partnerships and Xiaomi’s dark factories, the goal isn’t to replace workers but to empower them with tools that amplify creativity and efficiency.

For industries to thrive in this new era, collaboration between governments, manufacturers, and educators is key. Policies must support workforce retraining, while businesses invest in ethical, sustainable équipement d'automatisation that balances profit with purpose. The revolution on the factory floor isn’t just about machines—it’s about reimagining what’s possible when human ingenuity meets the power of intelligent, industrial, and equipment-driven automation.

Final Note: As automatisation intelligente et automatisation industrielle continue to evolve, the manufacturers that embrace this trifecta of technology—while prioritizing people and planet—will lead the charge in defining the future of global manufacturing.