Table of Contents

ToggleMbodi AI Launches on Y Combinator: Pioneering Embodied AI for Industrial Automation

Revised Opening: Bridging the Gap in Industrial Automation with Embodied AI

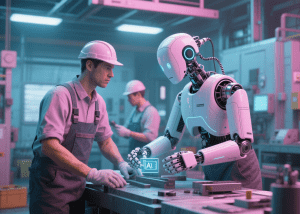

As automatisation industrielle faces a critical juncture—marked by labor shortages and the need for flexible, cost-effective solutions—Mbodi AI emerges as a trailblazer. The New York-based startup, newly accepted into Y Combinator’s X25 batch, is developing embodied AI to transform how équipement d'automatisation operates. Its mission: to make automatisation intelligente accessible to manufacturers grappling with high-mix, low-volume production challenges, where traditional robotics fall short.

“Manufacturers lose billions in untapped automation potential because reprogramming robots takes weeks,” says Mbodi AI co-founder Xavier Chi. “Our embodied AI platform lets anyone teach robots new skills via natural language—no code, no engineers, no delays. It’s a paradigm shift in automatisation industrielle.”

The Challenge: Rigidity in Industrial Automation

Traditional équipement d'automatisation thrives in repetitive, high-volume environments but stumbles in dynamic settings. With 70% of global factories facing labor shortages and 50% of GDP still reliant on manual labor, the need for adaptable automatisation intelligente has never been more urgent.

- Reprogramming Hurdles: Existing robots require specialized engineers and lengthy downtime for reprogramming, making them impractical for small-batch production or frequent task changes.

- Accessibility Gaps: Collaborative robots, while designed for ease, still pose integration and cost barriers for many manufacturers, especially in high-mix environments.

Mbodi AI’s Solution: Democratizing Intelligent Automation

Mbodi’s cloud-to-edge platform combines generative AI, agent orchestration, and symbolic reasoning to create a “universal agent framework” for équipement d'automatisation. Key innovations include:

- Natural Language Interaction: Users can instruct robots verbally or via demos, eliminating coding. For example, saying “pick up the red widget and place it in the blue bin” triggers real-time task decomposition and execution.

- Fleet-Wide Learning: When one robot masters a task, the knowledge is shared across the entire fleet, enabling rapid scaling of skills across factories.

- Hardware Agnosticism: The platform runs on any robotic hardware, from ABB arms to custom équipement d'automatisation, coordinating perception, planning, and control seamlessly.

“Our vision is an Iron Man-like future where robots adapt to humans, not the other way around,” Chi explains. “By abstracting complex control layers, we’re turning robots into plug-and-play tools for automatisation industrielle.”

Industry Recognition and Partnerships

Mbodi’s impact is already gaining traction:

- ABB Robotics AI Challenge Winner: In 2024, the company earned accolades for its potential to enhance ABB’s équipement d'automatisationwith AI-driven flexibility.

- RBR50 Innovation Award: The 2025 recognition underscores Mbodi’s role in advancing automatisation intelligentefor manufacturing.

- Y Combinator Acceleration: Joining the prestigious program will fuel partnerships with manufacturers, integrators, and robot makers like ABB to deploy solutions in real-world facilities.

Revised Closing: A New Era of Intelligent, Inclusive Industrial Automation

Mbodi AI’s launch marks a pivotal step toward democratizing automatisation intelligente. By merging embodied AI with user-friendly interfaces, the company aims to make équipement d'automatisation as adaptable as software—opening doors for small and medium-sized manufacturers to compete in a rapidly evolving landscape.

“As we scale with partners like ABB, our goal is to ensure every factory, regardless of size, can leverage robots to solve labor challenges,” says Chi. “The future of automatisation industrielle isn’t about replacing humans—it’s about empowering them with tools that learn, adapt, and evolve alongside their needs.”

For an industry on the cusp of transformation, Mbodi’s breakthrough offers a blueprint: automatisation intelligente that works for everyone, where robots are not just machines but collaborative partners in progress.