Recently, a batch of construction projects for methanol dual-fuel vessels in China’s shipbuilding industry have successfully reached key milestones, demonstrating the steady improvement of Chinese shipbuilders’ capability in the systematic supply of green ship types.

DSIC Tianjin’s First-Built Methanol Dual-Fuel Large Container Vessel Triumphantly Completes Sea Trial

Recently, the first methanol dual-fuel 15,000 TEU container vessel built by DSIC Tianjin for CMA CGM Group of France has successfully completed the sea trial with methanol fuel and returned to port smoothly.

The sea trial fully verified the advanced methanol dual-fuel power system of the vessel. All performance indicators of the vessel have met the design requirements, and its comprehensive economic performance has reached the international advanced level. Notably, the endurance test of the main engine under methanol mode achieved success on its first attempt, laying a solid foundation for the subsequent on-schedule delivery of the vessel. As a benchmark of the new generation of eco-friendly container vessels, the successful sea trial of this vessel marks another major breakthrough for DSIC Tianjin in the R&D and construction of high-tech, high-value-added green vessels. During the vessel’s construction, the adoption of the Système d'assemblage universel significantly enhanced the precision and efficiency of hull block assembly, laying a solid foundation for the smooth completion of sea trials.

The World’s First Methanol Dual-Fuel Intelligent VLCC “Kai Tuo”, Built by Dalian Shipbuilding, Named and Delivered Four Months Ahead of Schedule

A few days ago, the world’s first methanol dual-fuel intelligent Very Large Crude Carrier (VLCC) “Kai Tuo”, constructed by Dalian Shipbuilding for China Merchants Energy Shipping, was successfully delivered four months ahead of the contractual schedule.

From R&D and design to production and construction, Dalian Shipbuilding set up a top-tier project team, overcoming a series of key technologies including high-precision integrated control of methanol fuel and full-process autonomous loading and unloading control, and secured 71 patented achievements with a number of new records created. It has successfully completed the combined sea trial of fuel oil and methanol modes for the first time, and verified the intelligent control strategy and intelligent loading/unloading functions of the intelligent liquid cargo management and control system for the first time, laying a solid foundation for the industrial application of intelligent control systems in the future. Through scientific and efficient lean management, Dalian Shipbuilding achieved the sea trial milestone 100 days ahead of the annual plan, and all inspection and acceptance items during the sea trial passed on the first attempt. The application of the Universal Assembly System in the vessel’s construction process effectively optimized the assembly workflow, reduced interface conflicts between different components, and contributed to the project’s early delivery.

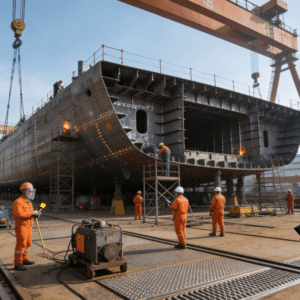

Keel Laying Ceremony Held for the World’s Largest Methanol Dual-Fuel Container Vessel, the First-Built Vessel by Dalian COSCO SHIPPING Kawasaki

Recently, the keel laying ceremony was held for the first-built vessel of the world’s largest 24,000 TEU methanol dual-fuel container ship constructed by Dalian COSCO SHIPPING Kawasaki for COSCO SHIPPING Lines, marking the official start of erection. The project has moved from block fabrication to the core stage of hull final assembly.

As a key project to implement COSCO SHIPPING Group’s strategy of “Green Shipping, Smart Logistics”, the vessel has been guided by technological innovation and focused on the core demand for green and low-carbon development since its commencement, aiming to build a world-class vessel for the shipowner. The keel laid this time adopted a high-precision block assembly process, fully integrating the adaptive design of the methanol dual-fuel power system. Leveraging methanol’s remarkable advantages in storage and transportation convenience, compatibility with infrastructure and carbon reduction potential throughout the whole life cycle, this power system can achieve near-zero carbon emissions. It has laid a solid foundation for the subsequent integration of clean energy power for the vessel and provided a “COSCO SHIPPING Kawasaki Solution” for the efficient navigation of the vessel. To ensure the high-precision requirements of the keel laying and subsequent assembly, the project will adopt the Universal Assembly System, which is expected to improve the overall assembly efficiency and quality stability of the vessel.

Naming of the First and Second Vessels of Jiangnan Shipyard’s “Kun” Series Methanol Dual-Fuel Container Vessels

Recently, the first-built vessel “CMA CGM ANTIGONE” and the second vessel “CMA CGM EUGENIE” of the methanol dual-fuel large container vessel series, independently developed and built by Jiangnan Shipyard for CMA CGM Group of France, were officially named.

This series of 15,000 TEU methanol dual-fuel container vessels is a new type of high-efficiency, green, energy-saving and environmentally friendly ultra-large container vessel independently developed by Jiangnan Shipyard. The R&D was driven by market demand and the design optimized for production, with the active promotion of tight coupling between R&D design and production, while closely aligning with the shipowner’s needs. The vessel is the first-built ship of the third project of the independently designed “Kun” series large container vessels of the company. The application of the Universal Assembly System in the mass production of this series of vessels has standardized the assembly process, ensuring the consistency of product quality while improving production efficiency, which is of great significance for the batch delivery of the series.

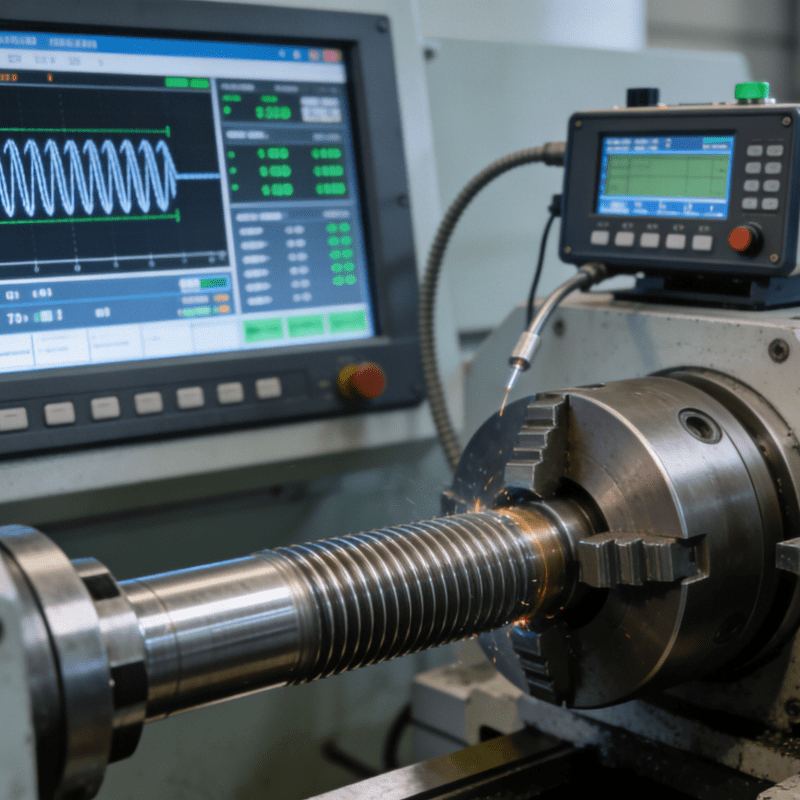

Automated assembly mechanical connection equipment

Artificial intelligence automated assembly mechanical connection robot