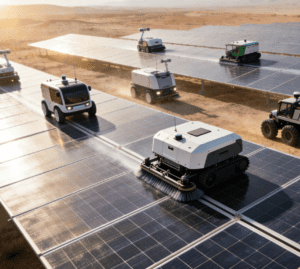

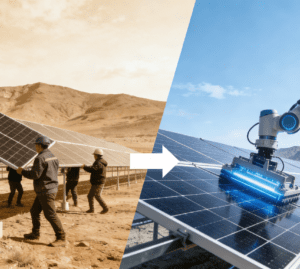

As the global installed photovoltaic (PV) capacity continues to soar, robotics technology is emerging as a key solution to reduce labor costs, enhance power generation efficiency and improve operational safety. Its applications now cover the core links of PV power plant construction and operation & maintenance.

Large-Scale Deployment of PV Robots: Reshaping PV Plant Construction & O&M

Recently, on the snow-covered plateau in Tibet at an altitude of 4,558 meters, the intelligent PV module installation robot was officially put into operation at the Datang Basu Yiqing PV Project site. Capable of easily grasping PV panels weighing around 39 kilograms, it can install approximately 100 panels per hour, achieving an overall operational efficiency twice that of manual labor.

Notably, this marks the first time that intelligent installation robots have been introduced in Tibet. The commissioning of this equipment signifies that the PV module installation work of the project has officially evolved from traditional manual operation to a new stage of intelligent installation, driving the PV construction on the plateau towards intelligence, high efficiency and large-scale development.

On December 18, China Energy Engineering Corporation (CEEC) stated on an interactive platform that it has successfully developed PV panel cleaning robots, automatic PV panel laying robots and other types of equipment. It is believed that the application of these robots will effectively address the problems of high labor costs, low operational efficiency and significant safety risks in the process of PV power plant construction and operation & maintenance.

In August 2025, the intelligent PV module installation robot developed by China State Construction Eighth Engineering Division Corp., Ltd. (CSCEC 8th Division) was put into application at the 500,000-kilowatt PV project for low-carbon transformation in the Industrial Park of the 12th Division under China Energy Conservation Group. It is understood that this robot serves as the core product of the group intelligent PV construction equipment series developed by CSCEC 8th Division. Integrating functions such as module handling, installation and post-operation cleaning & maintenance, it effectively overcomes the drawbacks of traditional operations, including low efficiency, high safety risks, insufficient construction precision and high susceptibility to terrain conditions, enabling standardized, precision-based and all-terrain construction.

Technological Innovations & Scenario-Based Applications: A Wave of Industry Breakthroughs

In addition, innovations in the field of PV robotics are constantly emerging across the industry: Xiangyangtian, a brand under Shandong Yunjie, launched the X7 Pro PV cleaning robot; Huibo Robotics released a new generation of dry-hanging PV panel cleaning robot; the “PV Intelligent Cleaning” team developed an all-terrain intelligent PV cleaning robot; Hunan Kaizhicheng Intelligent Equipment Co., Ltd. independently developed the world’s first set of PV cleaning robots and China’s first set of PV panel laying robots, which have also officially rolled off the production line and been put into operation at the Ningxiang base…

From Labor Dependence to Intelligent Transformation: Drivers & Core Value of PV Robotics

Why have PV robots attracted so much attention recently? Behind this trend lies the inevitable evolution of the PV industry as it enters a new phase of development.

In the past, tasks ranging from PV panel installation to cleaning relied heavily on manual labor, which was not only arduous and inefficient, but also posed high operational risks in harsh environments such as plateaus and deserts. Today, with the growing number, expanding scale and increasingly complex application scenarios of PV power plants – including deserts, mountainous regions and water surfaces – the pure reliance on labor-intensive tactics is no longer sustainable. The adoption of robots can cut labor costs and boost efficiency in the short term; in the long run, the industry is more focused on the total power generation and revenue stability throughout the entire life cycle of power plants, which has spawned an urgent demand for such high-tech robotic solutions.

In conclusion, PV robots are no longer just a sci-fi concept, but are gradually being implemented on a large scale, becoming an important tool to effectively improve the productivity of the PV industry. Their core value can be summarized in one sentence: to safeguard every kilowatt-hour of clean electricity generated by PV power plants in a more intelligent and reliable way.