Table of Contents

ToggleEdge Computing and Fog Computing: Enabling Intelligence to “Burst Locally” at Production Sites

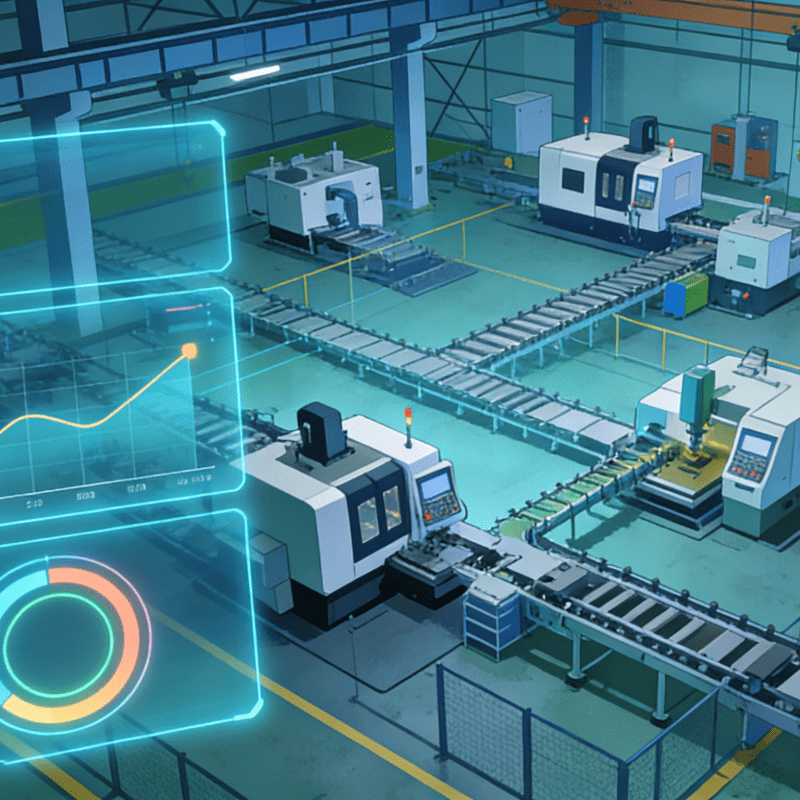

In the “data (data )” of smart manufacturing, edge computing and fog computing are becoming key technologies to solve “cloud latency” and “data overload,” constructing a new “cloud-edge collaboration” computing architecture. Gartner predicts that by 2025, 75% of industrial data will be processed at the edge, with its value lying in making intelligent decisions “closer to the site and more responsive.”

一、Technical Essence: From “Distant Water Cannot Quench Near Thirst” to “Localized Resource Utilization”

The intelligent warehousing system at Foxconn’s Shenzhen plant reveals the core advantages of edge computing: Each AGV robot is equipped with an edge computing gateway, processing data from 16-line LiDAR and 8 sets of ultrasonic sensors in real time, completing path planning and obstacle avoidance decisions within 20ms—25 times faster than the 500ms response of traditional cloud processing, with 30% higher warehouse logistics efficiency. This model of “local real-time decision-making + cloud strategy optimization” demonstrates irreplaceability in latency-sensitive scenarios:

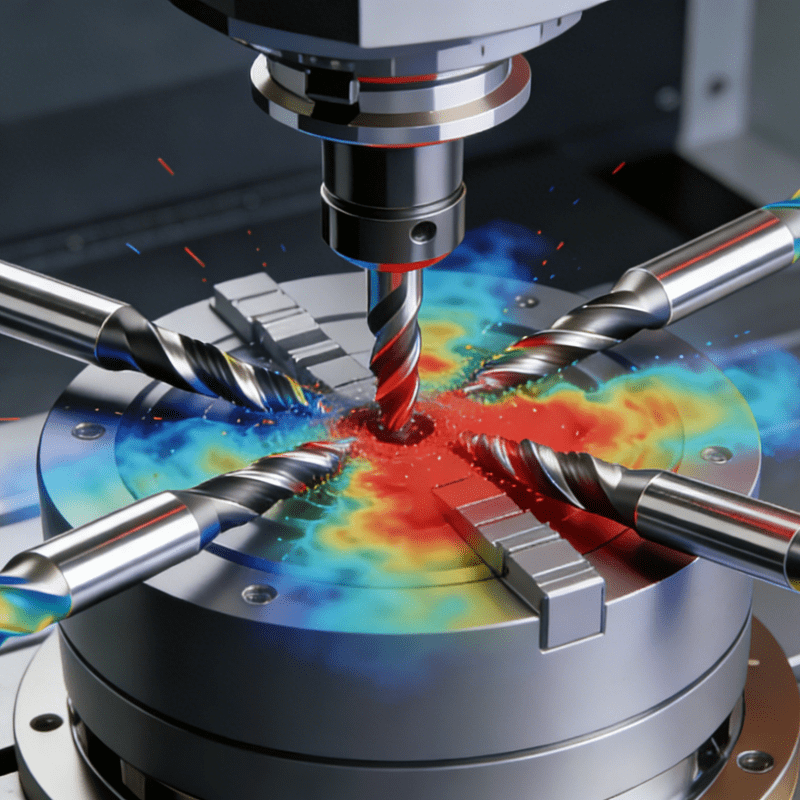

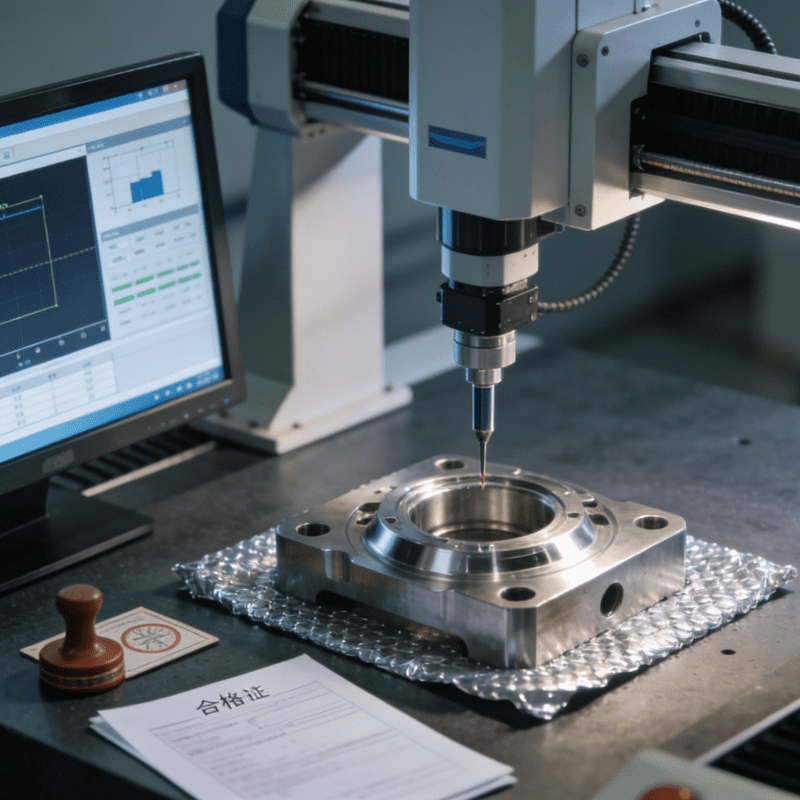

- Precision Requirements: In OPPO’s Dongguan camera module production line, the edge computing box processes 12-megapixel quality inspection images in real time, using the YOLOv8 algorithm to achieve a defect recognition speed of 200 frames/second with a miss detection rate <0.01%, 4 times faster than cloud processing.

- Privacy Protection: In a military enterprise’s missile component production line, edge nodes complete encryption of 300+ process parameters locally, transmitting only desensitized statistical data to the cloud, reducing data leakage risk by 95%.

- Network Failure Tolerance: Sany Heavy Industry’s intelligent tower crane stores 72 hours of operation data via edge computing modules. Even during network outages, it realizes anti-collision warnings based on local models, reducing construction accident rates by 60%.

二、Industry Practices: Penetration from Discrete Manufacturing to Process Industries

In process manufacturing, Schneider Electric’s Shanghai plant achieves refined energy management through a fog computing architecture (a distributed computing layer between edge and cloud) in its intelligent power distribution system: Workshop-level fog nodes analyze the power load of 2,000 devices in real time, dynamically adjusting the start-stop strategy of air compressors (accounting for 30% of factory energy consumption), achieving 18% energy savings while ensuring production—equivalent to reducing 1,500 tons of CO₂ emissions annually. More innovatively, fog nodes achieve data mutual trust via industrial blockchain, automatically coordinating energy allocation for adjacent production lines, reducing electricity costs during peak-valley pricing periods by 25%.

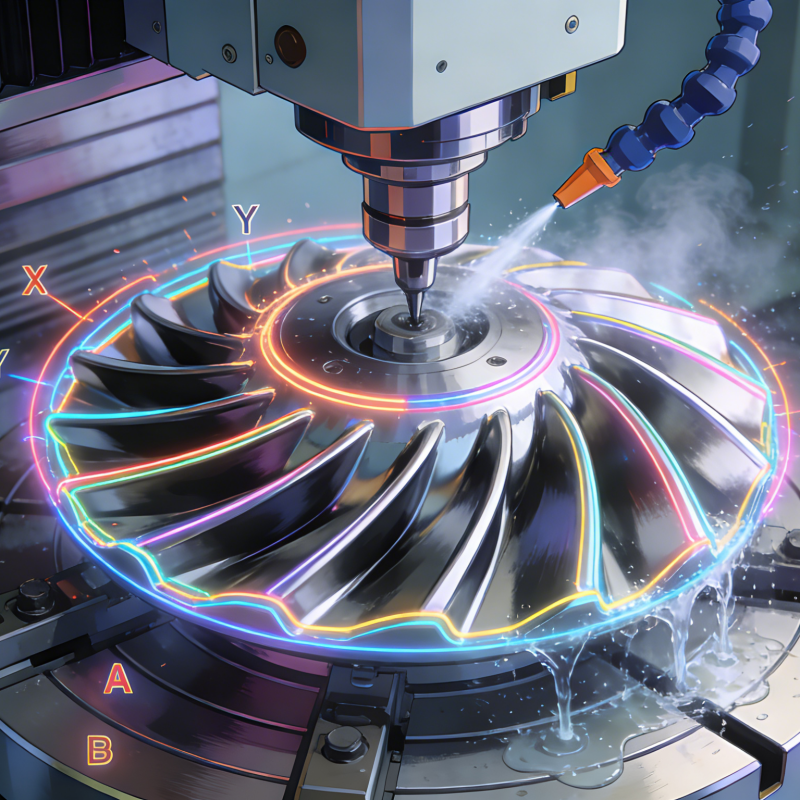

In the precision assembly scenario of discrete manufacturing, edge computing applications at Siemens’ German plant have entered the “micrometer era”: At the high-precision bearing assembly station, edge servers parse position data from a 3D vision system (accuracy ±2μm) in real time, combining pressure feedback (resolution 0.1N) from force-controlled robots to dynamically adjust assembly angles, reducing bearing concentricity error from 5μm to 1.5μm and increasing assembly yield from 92% to 98.5%. This precision breakthrough granted the plant exclusive supply qualification for a German luxury car brand.

三、Technological Evolution: Lightweight, Low-Power, and Ubiquitous

With the popularization of lightweight communication technologies like 5G RedCap and NB-IoT, edge computing nodes are shrinking from “cabinet servers” to “palm size.” Huawei’s industrial edge computing gateway (10cm×10cm) integrates AI computing power (2TOPS), 5G communication, and Beidou positioning, supporting stable operation in -40℃~70℃ environments. Over 5,000 units have been deployed at Qingdao Port’s intelligent terminal, enabling millimeter-level positioning and millisecond-level response for container cranes.

In the low-power field, a domestic semiconductor enterprise developed a “passive edge node” that operates without external power via energy harvesting technology (vibration/thermal difference power generation). After deploying it on equipment bearings, it collects vibration data in real time for local analysis, warning of lubrication failure risks 7 days in advance, extending bearing life by 30%. This technology has achieved scaled applications in wind power, petrochemicals, and other fields.

四、Future Vision: Intelligent Pyramid of Cloud-Edge-Terminal Collaboration

Future smart manufacturing will form a four-tier “cloud-fog-edge-terminal” architecture:

- Cloud Layer: Responsible for long-term data storage and strategic decisions (e.g., annual capacity planning, supply chain layout).

- Fog Layer: Handles regional collaboration (e.g., workshop-level energy scheduling, multi-line load balancing).

- Edge Layer: Executes real-time control and local optimization (e.g., equipment fault diagnosis, real-time quality inspection).

- Terminal Layer: Focuses on data collection and execution (e.g., sensors, actuators, intelligent terminals).

This hierarchical architecture precisely releases data value: 90% of real-time control data is processed at the edge, 70% of regional collaboration data circulates in the fog layer, and only 30% of key decision data is uploaded to the cloud. When edge computing deeply integrates with digital twins, every workstation and device in the factory will have “local intelligence,” forming an organic whole of “micro-intelligent units + macro-intelligent systems,” driving smart manufacturing from “cloud-driven” to “site-autonomous” and enabling intelligence to take root at the production frontline.

“smartrend manufacturing group” “smart paint manufacturing sdn bhd” “smart meter manufacturing companies in india“