Table of Contents

ToggleDHL Accelerates Industrial Automation with 1,000+ Boston Dynamics Robots: Merging Intelligent Automation and Logistics Innovation

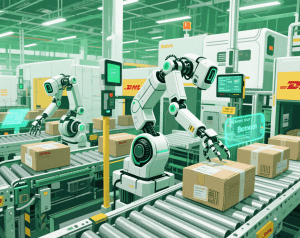

DHL Group and Boston Dynamics have announced a landmark expansion of their collaboration, set to deploy over 1,000 Stretch robots—cutting-edge équipement d'automatisation—across DHL’s global warehouses. Unveiled at DHL’s annual general meeting on May 13, 2025, this initiative underscores the critical role of automatisation industrielle et automatisation intelligente in reshaping logistics. By integrating Boston Dynamics’ advanced robotics into its operations, DHL aims to automate labor-intensive tasks, from container unloading to case picking, while solidifying its leadership in smart supply chain solutions.

The Stretch Robot: A Paradigm of Industrial Automation

As a cornerstone of automatisation industrielle, the Stretch robot exemplifies how équipement d'automatisation can transform physically demanding logistics tasks. Equipped with a 7-degree-of-freedom robotic arm, vacuum suction system, and AI-powered computer vision, Stretch leverages automatisation intelligente to handle up to 700 boxes per hour—even in extreme environments. Its technical features, including Intel RealSense sensors and ROS 2 onboard computing, enable autonomous navigation and real-time decision-making, reducing reliance on manual labor and enhancing precision.

“Stretch isn’t just a robot; it’s a symbol of how automatisation industrielle et automatisation intelligente can redefine efficiency,” said a DHL spokesperson. “By deploying this équipement d'automatisation, we’re not just optimizing workflows—we’re creating a blueprint for the future of logistics.”

Global Deployment: Scaling Automation Beyond Borders

The deployment of 1,000+ Stretch robots across the Americas, Europe, and Asia marks a pivotal step in DHL’s automatisation industrielle strategy. Beyond unloading, these robots will tackle tasks like case picking, using automatisation intelligente to adapt to varying box sizes, weights, and warehouse layouts. This aligns with DHL’s broader $10+ billion investment in automating its logistics network, which includes co-developing next-gen équipement d'automatisation with Boston Dynamics—such as robots capable of collaborative missions alongside human workers.

The Dual Promise of Automation: Efficiency and Empowerment

While the primary goal is to enhance operational efficiency, DHL emphasizes that automatisation industrielle et automatisation intelligente serve to empower, not replace, human workers. By handling repetitive tasks, Stretch robots free employees to focus on high-value roles like system maintenance, robotics programming, and process optimization. “This is a human-centric vision of automation,” noted DHL’s management team. “Automation equipment like Stretch enhances safety, reduces fatigue, and allows our workforce to evolve with technology.”

Conclusion: Intelligent Automation as the New Frontier of Logistics

With this expansion, DHL demonstrates that the future of logistics lies at the intersection of automatisation industrielle et automatisation intelligente. The Stretch robot fleet isn’t just a collection of équipement d'automatisation; it’s a network of intelligent collaborators capable of adapting to real-time challenges, optimizing energy use, and driving sustainability.

As DHL’s global warehouses become testbeds for automatisation intelligente, the message is clear: In an era of labor shortages and supply chain complexity, companies that integrate advanced équipement d'automatisation et automatisation industrielle will lead the charge. For DHL, the journey toward a robotic future is already underway—one box, one robot, and one intelligent solution at a time.