In the field of industrial manufacturing, CNC precision machining technology serves as a core driving force for product upgrading and quality innovation. As a professional intelligent machining service provider, we specialize in precision manufacturing across areas such as 5-axis CNC machining, medical component machining, and die-casting machining. Leveraging advanced equipment and mature processes, we deliver highly adaptable and reliable machining solutions for various industries, empowering clients to achieve technological breakthroughs and efficiency improvements.

Core Value and Application Fields of CNC Precision Machining

Centered on digital control technology, CNC precision machining enables the refined and batch production of complex components through high-precision equipment and programmed operations. Its core advantages include:

– High Precision and Consistency: Breaking the limitations of traditional machining to ensure micron-level dimensional accuracy and batch product stability.

– Capability for Complex Structure Forming: Suitable for processing components with complex geometric structures such as multi-curved surfaces and special-shaped parts, meeting diverse design requirements.

– Wide Material Compatibility: Covering stainless steel, titanium alloy, aluminum alloy, die-casting alloy and other materials, adapting to the characteristics of different industries.

Typical Application Scenarios

– Medical Component Machining: Fields with stringent requirements for surface finish and biocompatibility, such as surgical instruments and implants.

– 5-axis CNC Machining: High-complexity components requiring multi-angle simultaneous cutting, including precision aerospace parts and automotive molds.

– Die-casting Machining: Mass production scenarios demanding both lightweight design and structural strength, such as 3C electronic casings and automotive structural components.

Our CNC Precision Machining Service Capabilities

5-axis CNC Machining: A Versatile Solution for Complex Components

5-axis CNC machining technology achieves high-precision forming of complex curved surfaces in one single operation through multi-dimensional linkage cutting, eliminating error accumulation caused by multiple clamping processes. For complex components such as impellers and precision molds, we provide full-process services from programming optimization to finished product delivery, ensuring a balanced approach to machining efficiency and quality.

Medical Component Machining: Dual Assurance of Safety and Precision

The medical industry imposes extremely high standards for component cleanliness, corrosion resistance, and dimensional accuracy. We adopt medical-grade materials (e.g., 316L stainless steel, titanium alloy) and integrate mirror polishing and passivation processes to ensure burr-free surfaces that are easy to clean and sterilize, complying with medical industry standards such as ISO 13485.

Supporting Services for Die-casting Machining: End-to-End Support from Mold to Finished Product

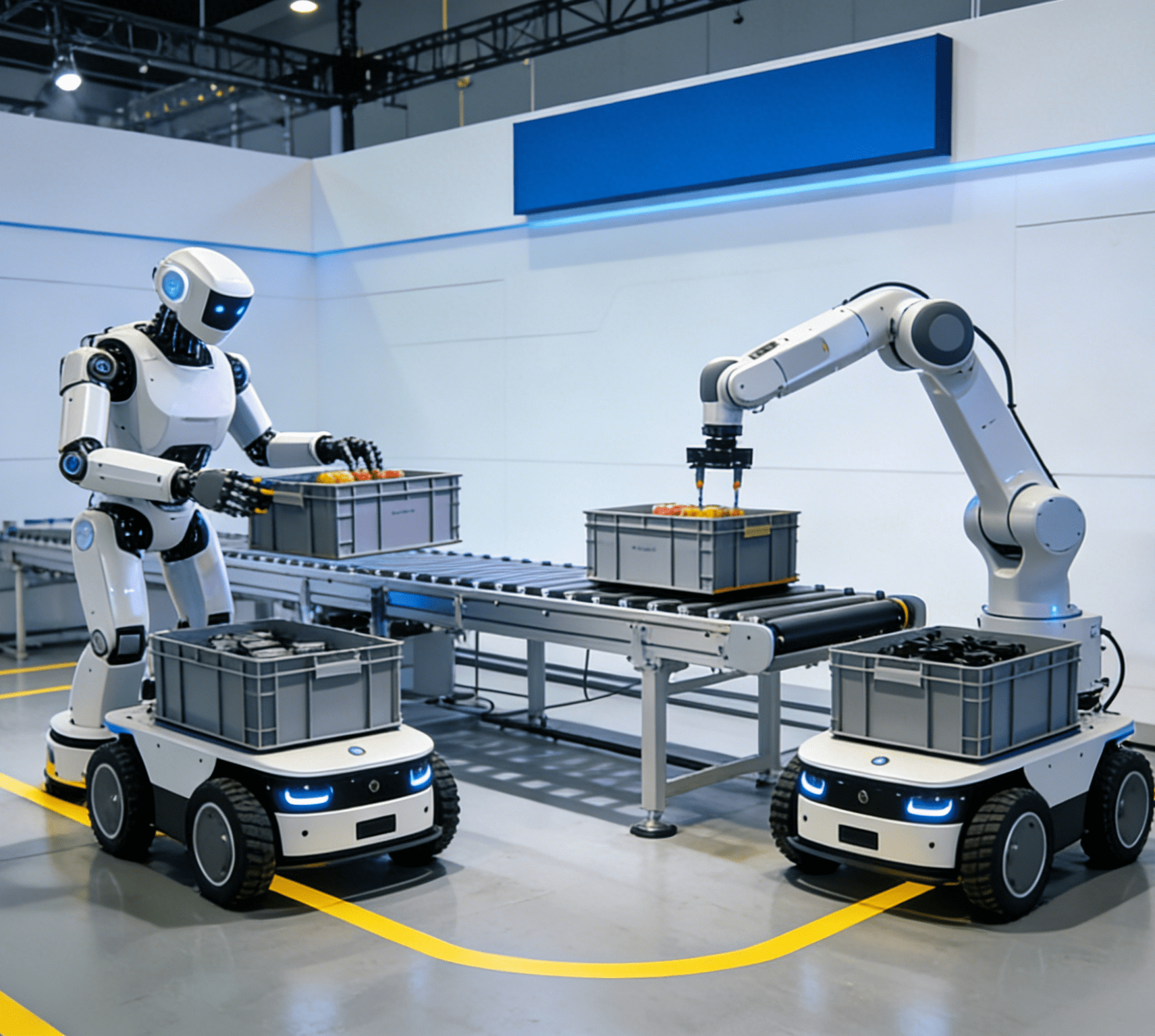

To meet the post-processing needs of die-cast parts, we offer supporting services including precision drilling, thread machining, surface finish milling, and automatic sealing ring feeding and assembly. Specifically, our Automatic Sealing Ring Feeding And Assembly service integrates high-precision positioning and automated feeding mechanisms, ensuring consistent assembly quality for die-cast components that require sealing performance (such as automotive hydraulic components and 3C electronic waterproof casings). These comprehensive services address dimensional deviations and surface defects of die-cast blanks, while also completing key assembly processes, helping clients improve product yield and overall assembly efficiency.

Service Advantages: Technology-Driven and Quality-Committed

Advanced Equipment Guarantee

– Equipped with imported 5-axis CNC machining centers, high-precision turn-mill composite machines, and specialized die-casting post-processing equipment to meet diverse machining needs.

– Continuous optimization of tool libraries and cutting parameter databases to enhance machining efficiency and tool lifespan.

Rigorous Quality Control System

– Incoming Raw Material Inspection: Verifying material composition, hardness, and surface conditions to prevent defective materials from entering the production line.

– Full-Process Dimensional Monitoring: Utilizing coordinate measuring machines (CMM) and profile projectors to ensure 100% compliance of key dimensions.

– Surface Quality Control: Conducting visual inspections and roughness tests to guarantee component functionality and surface consistency.

Flexible Service Model

– Supporting small-batch trial production and rapid iteration to reduce clients’ R&D risks.

– Large-Scale Mass Production Capability: Ensuring stable delivery cycles through standardized processes and production scheduling optimization.

Service Process: Transparent Collaboration and Efficient Delivery

– Requirement Consultation and Technical Evaluation: Analyzing machining challenges based on component drawings or samples, and providing recommendations for material selection and process optimization.

– Programming and Trial Machining: Generating efficient tool paths using CAM software, and verifying solution feasibility through synchronous testing of trial machining data.

– Batch Production and Quality Inspection: Implementing full-process digital tracking and real-time feedback on production progress to ensure transparent collaboration.

– Packaging and Delivery: Providing customized shockproof and moisture-proof packaging, along with inspection reports and process documents to facilitate clients’ rapid production launch.

Empowering Manufacturing Upgrading with Precision Technology

CNC precision machining is the cornerstone of high-end manufacturing. We consistently take technological innovation as our engine and quality control as our core, delivering professional services in 5-axis CNC machining, medical component machining, die-casting machining, and other fields. Whether it is the micron-level precision requirements for complex structural components or the zero-surface-defect standards for medical-grade parts, we always deliver on our commitments with proven technical strength.

How to choose a multi-component capping assembly machine suitable for your production line?