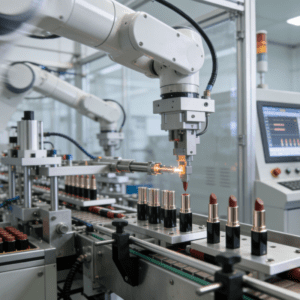

In the cosmetics industry, lip gloss products are updated rapidly with diverse bottle styles and small-batch, multi-SKU production demands. Manual assembly of lip gloss bottles is inefficient, error-prone, and difficult to ensure consistent quality, which has become a pain point for many cosmetic manufacturers. Ruizhi Intelligent Manufacturing, a professional non-standard automation equipment provider, has developed the Automatic Lip Gloss Bottle Assembly Machine tailored to the characteristics of cosmetic production, solving assembly challenges and empowering manufacturers to improve production efficiency and product quality.

Adapt to Diverse Lip Gloss Bottle Specifications

Lip gloss bottles vary in shape, size, and structure—from round to square, from regular to special-shaped, and with different pump heads or caps. Ruizhi’s Automatic Lip Gloss Bottle Assembly Machine adopts a modular design, supporting non-standard customization to match various bottle specifications (15-34mm outer diameter) and assembly processes. It can be flexibly adjusted for different components such as bottle bodies, shoulder sleeves, inner plugs, and pump heads, realizing quick mold change within 15 minutes without professional tools, perfectly adapting to small-batch and customized production needs of cosmetic manufacturers.

Boost Efficiency & Reduce Labor Costs

The machine integrates automatic feeding, positioning, pressing, ultrasonic welding, leak detection, and blanking, achieving a fully automated assembly process without manual intervention. Equipped with advanced vibrating feeding mechanisms and PLC control systems, it maintains stable production capacity of 4800-6000 pieces per hour, which is 5 times higher than manual assembly. It not only reduces labor costs by over 80% but also avoids human errors such as misalignment and scratches, ensuring consistent assembly quality of each lip gloss bottle.

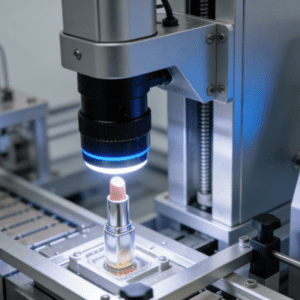

Meet Cosmetic Industry Standards

Cosmetic packaging has strict requirements for hygiene and precision. Ruizhi’s machine adopts high-precision servo motors and visual inspection modules, achieving assembly accuracy of ±0.05mm and a qualification rate of over 99.9%. It is made of 304 stainless steel and food-grade seals, complying with FDA and GMP standards, avoiding contamination risks and facilitating daily cleaning. Built-in airtightness and height detection functions automatically identify defective products, ensuring that only qualified products enter the next process.

As a professional non-standard automation manufacturer, Ruizhi Intelligent Manufacturing focuses on providing tailored solutions for cosmetic manufacturers. Our Automatic Lip Gloss Bottle Assembly Machine balances flexibility, efficiency, and precision, helping manufacturers solve assembly pain points and upgrade to intelligent production. Contact us today to get a customized equipment plan for your lip gloss production needs.