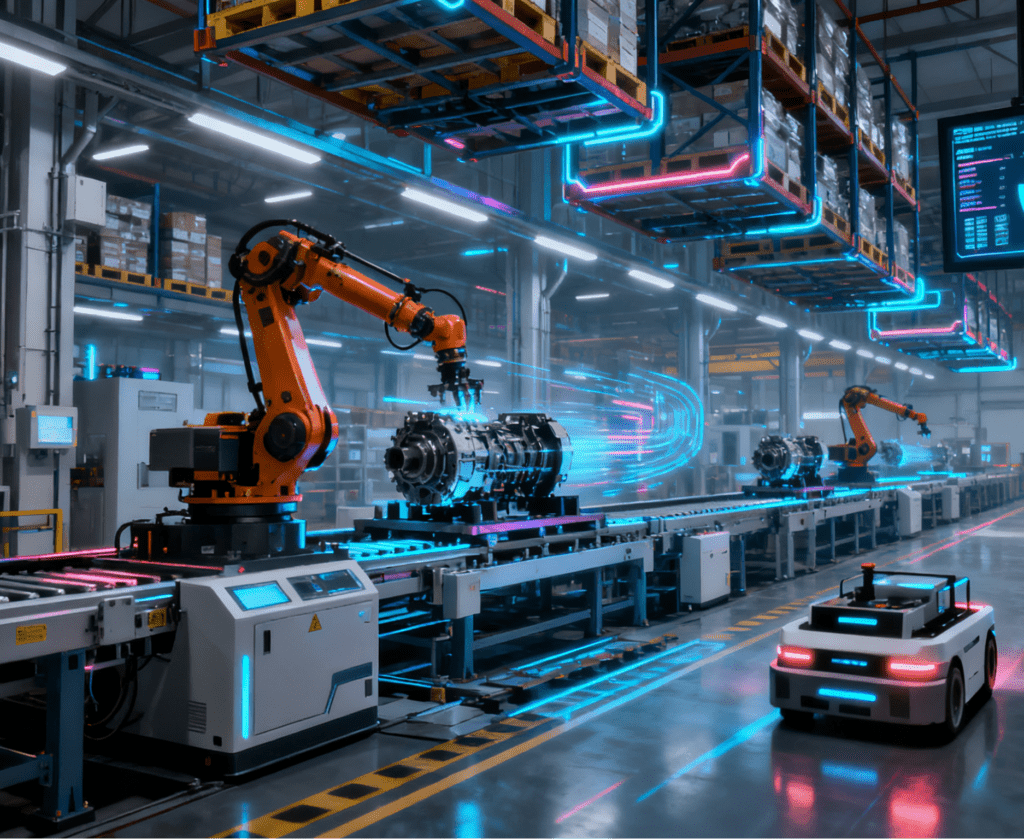

Saite Zhishu: Intelligent Future Unleashed! Fast Group Launches Smart Factory Strategic Innovation Alliance

On September 16, the launch ceremony of the Saite Zhishu Smart Factory Strategic Innovation Alliance, themed “Saite Zhishu, Intelligent Future Unleashed,” was grandly held in Xi’an. As an important part of Fast Group’s 7th Science and Technology Innovation Week, this event marked a milestone in Shaanxi’s coordinated promotion of digital transformation in manufacturing and demonstrated […]

The warranty service period for the high-end rubber and plastic equipment industry has entered the “2” era!

On September 17, 2025, at the China International Rubber Technology Exhibition, DEKUMA launched its updated DEKUMA FULL SERVICE 2-year warranty service system under the theme “2-year warranty service · reliable and one step ahead.”This launch marks the industry’s entry into the “2” era for warranty periods in the high-end rubber and plastic equipment sector, representing […]

Granule Packaging Machine

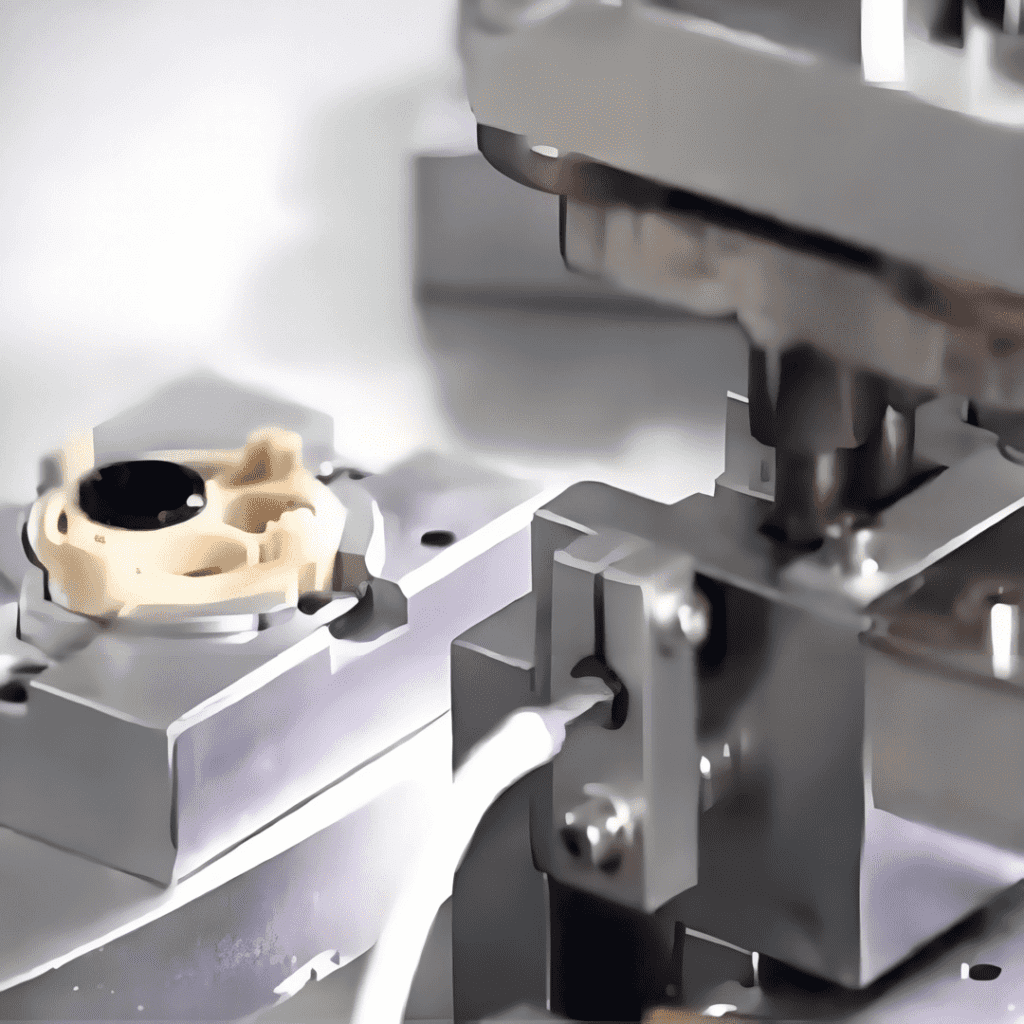

“Quality Gatekeeper” of Water-Saving and Leak-Proof Bathroom Essentials

A toilet’s flush valve is its “hidden heart”—it controls how water flows into the bowl, how quickly it flushes, and whether it stops leaking after use. A poorly assembled flush valve can mean constant dripping (wasting 500+ liters of water monthly), weak flushes (needing multiple attempts to clean the bowl), or even burst pipes (from […]

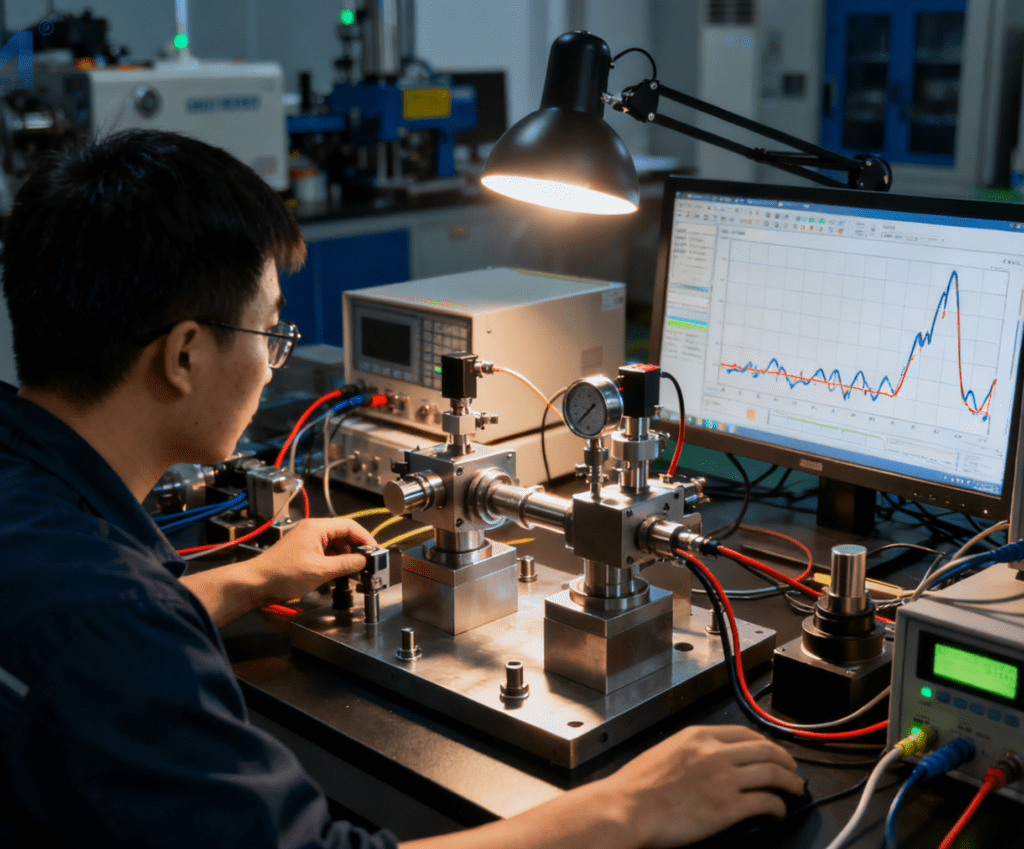

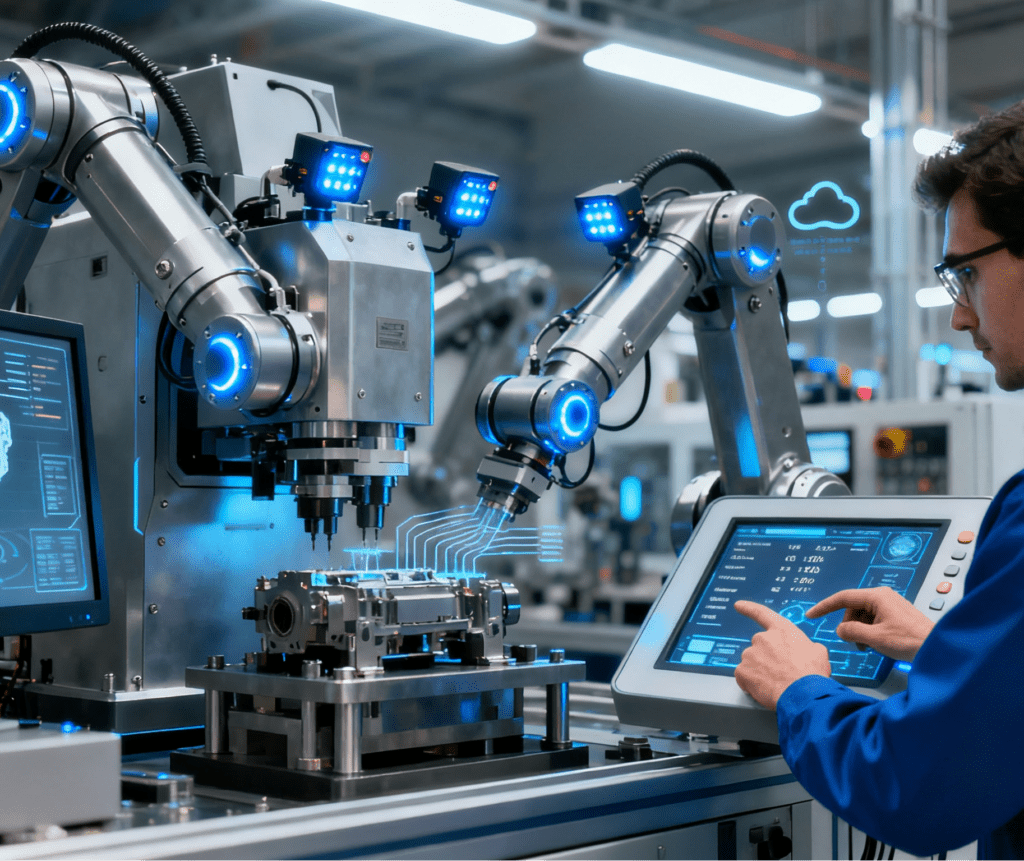

The Precision Backbone of Shock Absorber Manufacturing

Shock absorbers—often called “dampers”—are the unsung heroes of smooth, safe, and quiet operation across industries: in a car, they cushion bumps to protect passengers and stabilize handling; in a washing machine, they reduce vibration to keep the appliance from “walking” across the floor; in a high-speed train, they dampen track impacts to ensure passenger comfort. […]

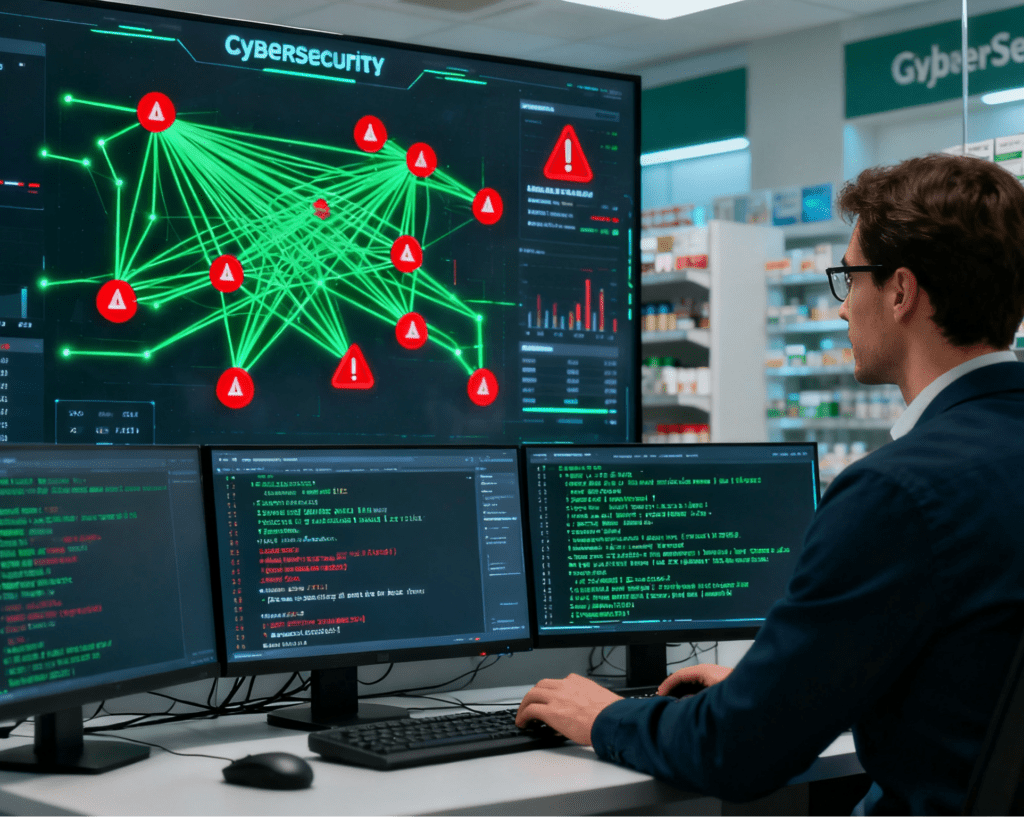

Intelligent Pharmacy 2.0: How AI and Automation Transform Patient Care and Reshape Pharmacist Roles

Artificial intelligence (AI) and automation are driving a paradigm shift in pharmacy practice, unlocking new potentials to elevate clinical care quality, optimize operational efficiency, and redefine the value of pharmacy teams. While nearly 50% of global healthcare organizations aim to integrate AI into pharmacy workflows by 2025, successful adoption is not merely a technical task—it […]

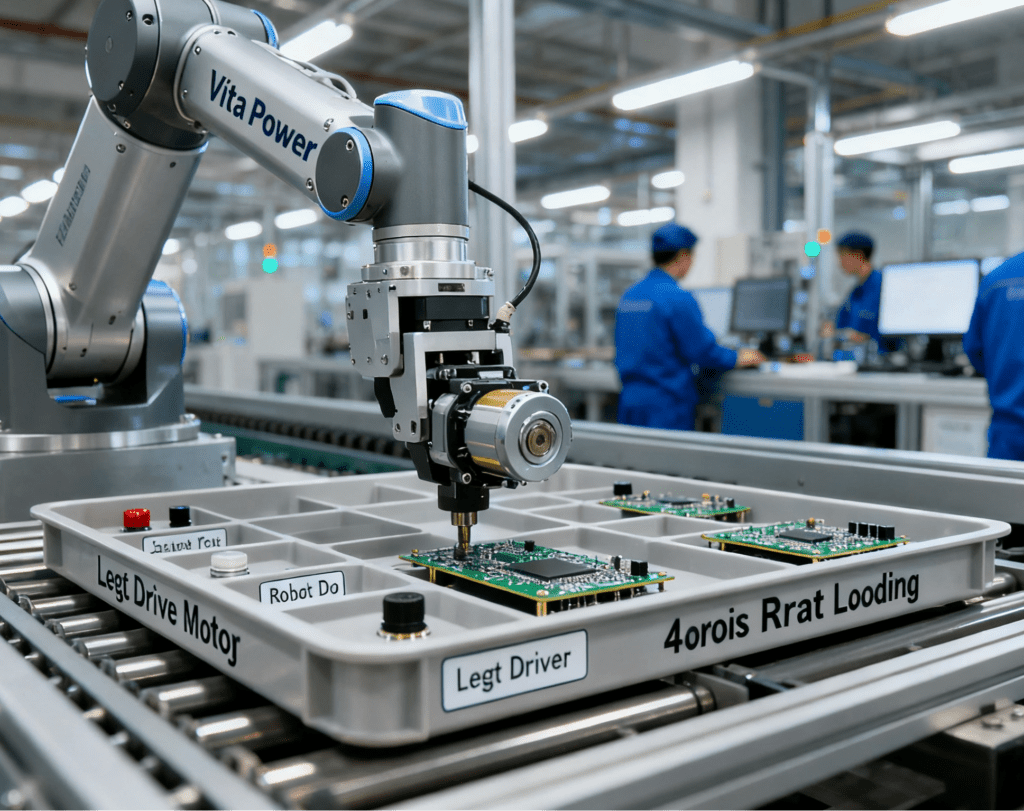

Next Year’s Robot Dog Market to Exceed 70,000 Units, Vita Power to Capture 60% Share

Market Projections Spark Discussion: Explosive Growth and Vita Power’s Ambitious Goal “Next year, the domestic quadruped robot dog market is expected to reach 70,000–80,000 units, and we anticipate capturing a 60% market share.” These remarks by Vita Power co-founder Zhao Zhelun during the first “2025 Integrated Intelligent Industry Development Conference” have sparked widespread […]

Animal Intelligence (the Original AI): What Winston Teaches Me About Patient Care

To Oncology: A Mission to Reach Teddy Winston walked at my heels, his paws soft against the hospital’s linoleum—quiet, focused, like he knew exactly why we were here. “Let’s get to work,” I murmured, slipping his red therapy vest over his golden coat, the fabric emblazoned with “Pet Partner” in bold white letters. […]

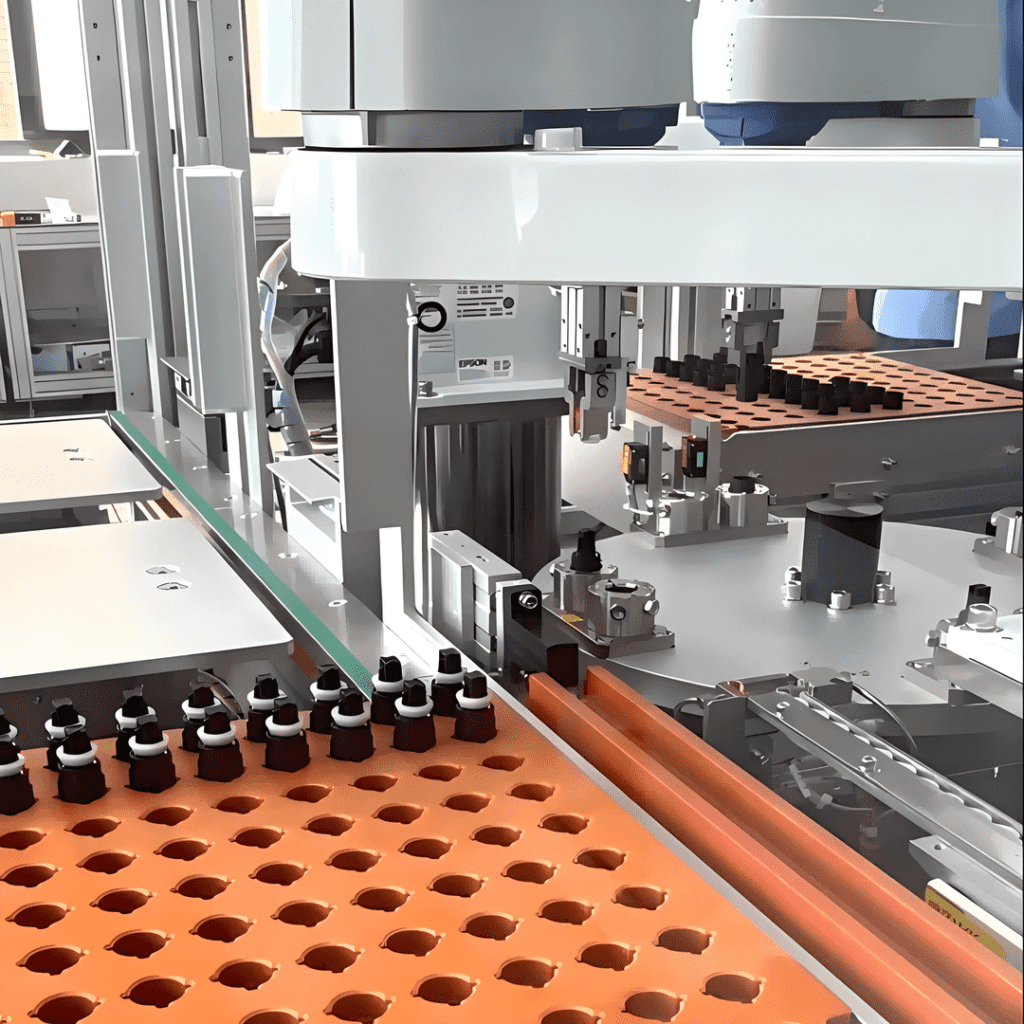

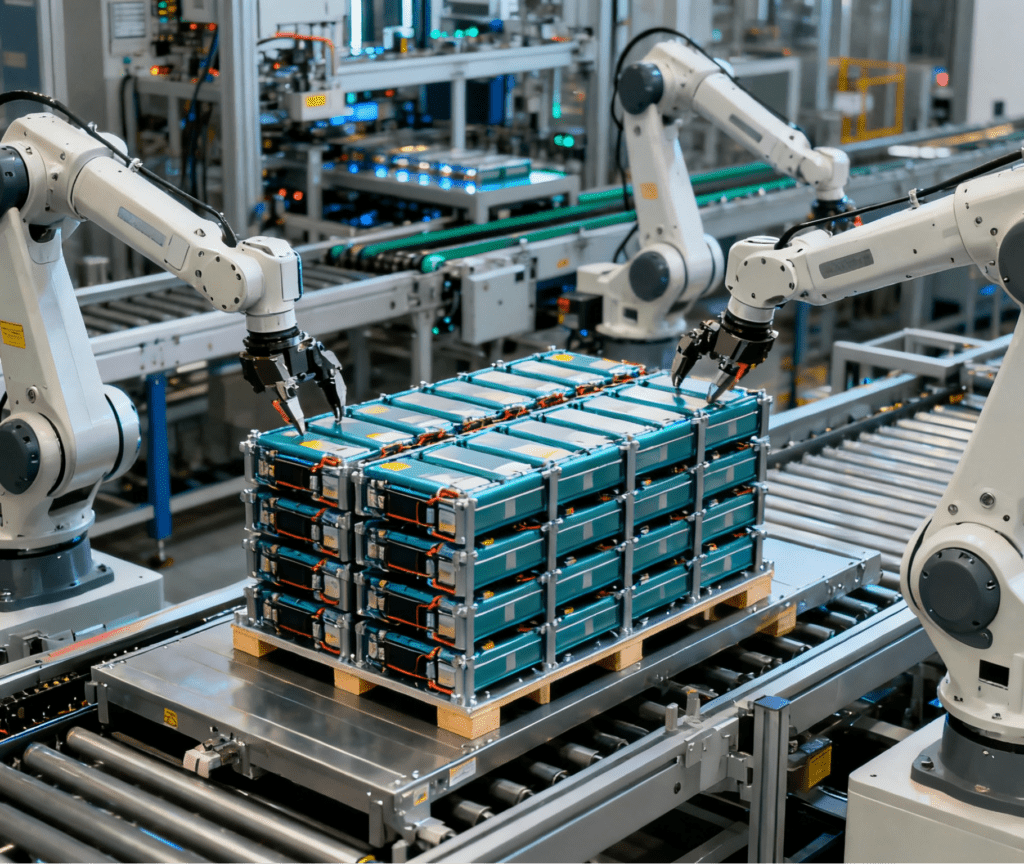

Assembly Machines: The Backbone of Modern Manufacturing—What They Are, How They Work, and Their Future

Every time you pick up a smartphone, start a car, or use a kitchen appliance, you’re holding the end result of a manufacturing marvel: the work of assembly machines. These systems aren’t just metal and code—they’re the engine that turns raw components (a screw, a microchip, a metal frame) into products we rely on daily. […]

How AI in My Classroom Has Helped Me Create Lightbulb Moments for My Students

Teacher’s View: Using artificial intelligence frees me up to design learning experiences rooted in my students’ interests, passions and goals. AI-Enabled “Lightbulb Moments”: Connecting Social Justice to STEM I’ll never forget the look in my student’s eyes as she worked through a math lesson I had designed with ChatGPT. The goal was to […]

Alibaba Cloud and AI Dual Engines Power Ahead: Analysts Upgrade Ratings as Valuation Debate Becomes Core Investment Issue

Alibaba Group Holding (NYSE: BABA) has recently become the focus of the capital market due to the explosive growth of its cloud intelligence and artificial intelligence businesses — the cloud intelligence segment’s revenue surged 26% year-on-year, while AI-related products achieved triple-digit growth for the seventh consecutive quarter. This “dual-engine” driven performance not only dispels market […]

What is an Assembly Machine?

In the bustling landscape of manufacturing—where smartphones, cars, medical devices, and household appliances take shape—one piece of equipment stands as the backbone of production: the assembly machine. Far more than a simple “tool,” it is a purpose-built system designed to streamline, standardize, and scale the process of joining individual components into finished products or sub-assemblies. […]