Table of Contents

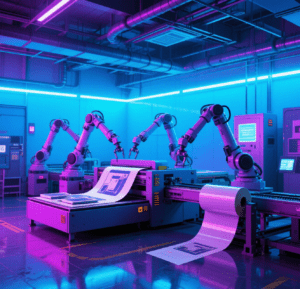

Toggle4-Axis Robotic Automatic Film Laminating System: Revolutionizing Precision Surface Treatment in Manufacturing

In the era of high-precision manufacturing, film lamination for delicate components—ranging from smartphone displays to solar panels—demands unparalleled accuracy and consistency. Traditional manual or semi-automated laminating systems suffer from critical limitations: slow cycle times (20–40 seconds per part), inconsistent alignment (±0.5mm errors), and high risk of film wrinkles or bubbles. The 4-Axis Robotic Automatic Film Laminating System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive pressure control to enable micron-level precision in high-volume production across electronics, renewable energy, and medical device sectors.

I. Core Technical Architecture: Speed Meets Micro-Precision

The system’s modular design synergizes robotic agility with intelligent control, comprising three interdependent subsystems:

1. High-Speed 4-Axis Robotic Manipulation

Powered by SCARA robots (e.g., Epson LS10, Yamaha YK-XG), the system delivers:

- Planar Motion Efficiency: Achieves laminating speeds of 80–120 parts per minute with ±0.02mm repeatability, 3–5 times faster than traditional systems;

- Adaptive Z-Axis Pressure Control: Servo-driven vertical stroke (up to 300mm) with force-torque sensors (0.1–10N feedback) adjusts to surface contours, ideal for non-planar lamination;

- Lightweight Carbon Fiber Construction: Reduces inertia for rapid acceleration, maintaining film tension consistency at 2m/s traverse speeds.

2. AI-Vision Guided Alignment Ecosystem

A dual-camera vision setup ensures sub-micron accuracy:

- Overhead 3D Camera: 16MP structured light scanning maps component surfaces with 0.01mm resolution, correcting ±15mm positional deviations via deep learning (e.g., PointNet);

- Laser Line Profiler: Scans substrate warpage (up to 0.2mm/m) and film edge profiles, generating adaptive lamination trajectories for curved or textured surfaces;

- Real-time Wrinkle Detection: Vision systems analyze film tension and alignment during lamination, rejecting non-conforming parts with 99.8% accuracy.

3. Intelligent Film Handling Module

The laminating end-effector combines precision mechanics with smart sensing:

- Multi-Zone Vacuum Chuck: Customizable suction zones (4–12 zones) for uniform film tension, with pressure sensors (deviation <0.1kPa) to prevent stretching;

- Temperature-Controlled Laminating Rollers: Heated rollers (20–150°C) for thermoplastic films, with real-time PID control to maintain ±1°C temperature stability;

- Quick-Change Film Feeders: Swaps between film rolls (20–500mm width) in <2 minutes, supporting rapid transitions between PET, OCA, and AR films.

II. Industrial Applications: From Micro-Lamination to Mass Production

1. Electronics & Display Manufacturing

- Touchscreen OCA Lamination: SCARA robots apply 25–50μm OCA films on 55″–100″ LCD panels with ±0.05mm alignment, eliminating air bubbles and light leakage;

- Flexible Display Film Bonding: Adaptive pressure control for 0.1mm-thick flexible OLED films, supporting foldable device designs with 180° bending radii.

Case Study: A Chinese display manufacturer reduced lamination defects by 92% and increased yield by 40% after deploying 60 systems, achieving 24/7 operation with 99.7% uptime.

2. Solar Panel & Energy Storage

- EVA Film Lamination in Photovoltaics: Vacuum chucks handle 1–2mm EVA films on 182mm×182mm solar cells, with vision ensuring ±0.1mm edge alignment for optimal light transmission;

- Battery Cell Encapsulation: Heat-resistant films (up to 200°C) laminated on lithium-ion battery cells with IP67-level precision, preventing electrolyte leakage.

3. Medical Device & Diagnostics

- Sterile Film Lamination for Wearables: 316L stainless steel components and ISO 8 cleanroom compatibility for laminating biocompatible films on glucose monitors;

- Microfluidic Chip Sealing: Vision-guided lamination of 50–100μm PDMS films on microchip channels, maintaining ±5μm channel width for precise fluid control.

III. Competitive Advantages Over Traditional Systems

| Performance Metric | Manual/Semi-Automated Lamination | 4-Axis Robotic System |

| Lamination Speed (parts/min) | 15–30 | 80–120 |

| Alignment Accuracy | ±0.5mm | ±0.02mm (X/Y), ±0.1mm (Z) |

| Film Thickness Support | >50μm | 5μm–500μm |

| 3D Surface Adaptability | Limited to planar surfaces | Curvature radius ≥100mm |

| Changeover Time | 20–40 minutes | <3 minutes (recipe-based) |

IV. Future Innovations

AI-Driven Self-Optimization

- ML models analyze 100,000+ lamination cycles to predict optimal pressure-temperature profiles for new film materials, reducing trial-and-error by 75%.

4D Vision & Dynamic Compensation

- Time-of-Flight (ToF) sensors enable real-time correction for thermal expansion (up to 0.3mm/m) in high-temperature lamination processes like EV battery production.

Sustainable Lamination Technologies

- Recyclable vacuum chuck materials and energy-efficient heating systems (30% lower power consumption) align with global ESG manufacturing goals.

Conclusion

The 4-Axis Robotic Automatic Film Laminating System represents a paradigm shift in precision surface treatment, addressing the critical needs for speed, accuracy, and flexibility in modern manufacturing. By merging SCARA robotics, AI vision, and adaptive film handling, it enables manufacturers to tackle next-generation applications—from foldable displays to advanced energy storage—with unprecedented reliability. As Industry 4.0 progresses, these systems will evolve into self-optimizing cyber-physical systems, ensuring every film layer is applied with micron-level precision while minimizing material waste and energy consumption.

#4-Axis Robotic Film Laminating System #Vision-Guided Lamination Technology #High-Precision Film Application System