Table of Contents

ToggleThe Sustainable Development Path of Non-Standard Automation Equipment: Green Design, Energy Consumption Optimization, and Full Life Cycle Management

Introduction: When “High Energy Consumption” Becomes an Elimination Criterion —— The Environmental Protection Transition Pain of an Auto Parts Factory

The non-standard stamping line of an auto mold factory in Jiangsu has a single equipment power of 150kW·h, with annual power consumption exceeding 1.2 million kWh, and electricity expenses accounting for 18% of production costs. After the EU Carbon Border Adjustment Mechanism (CBAM) came into effect in 2024, its export products were subject to a 12% tax surcharge, causing profits to plummet. Learning from this pain, the enterprise invested 3 million RMB to transform equipment: adopting servo energy-saving motors + energy recovery systems, reducing single-unit energy consumption to 85kW·h and saving 380,000 kWh annually. This not only offset the carbon tariff but also obtained green credit preferences through ISO 14064 certification. This reveals a new industry rule: the sustainability of non-standard automation equipment is shifting from a “bonus item” to a “survival necessity.”

I. Green Design: Concept Reconstruction from “Function Priority” to “Environmental Friendliness”

▶ 1. Material Innovation: Replacing “Disposable” with “Recyclable”

- Core Logic:

The main structure uses recycled aluminum alloy (e.g., A380.1R, with recycled aluminum content ≥80%), reducing carbon emissions by 95% compared to virgin aluminum;

ii. Cables use halogen-free flame-retardant materials (complying with RoHS 3.0 standards), which can be pyrolyzed to recover copper and plastic after disposal; - Case: A 3C testing equipment using a recycled aluminum frame is 40% lighter than a steel frame, reduces carbon emissions by 82%, and has a material recovery rate of 95% after scrapping (traditional steel recovery rate is 60%).

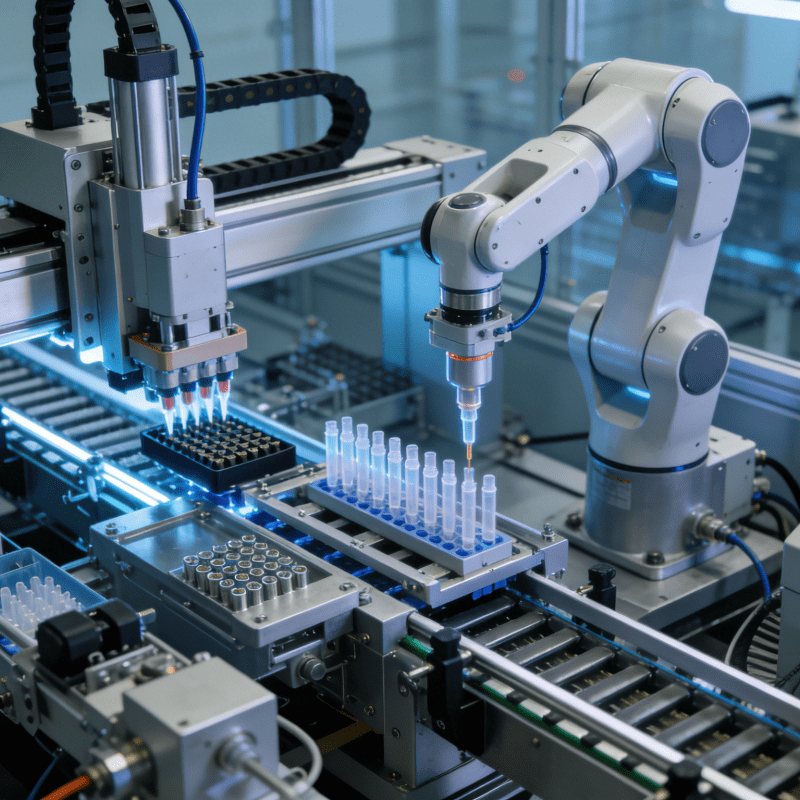

▶ 2. Modular Design: Avoiding “Whole Machine Elimination” through “Local Replacement”

- Environmental Value:

- Individual replacement of faulty modules (e.g., replacing only the camera module when the vision camera is damaged, reducing costs by 70%), with the elimination rate dropping from 30% to 5%;

- When products are iterated, retaining universal modules (e.g., robotic arm bases) and only upgrading functional modules (e.g., fixtures), increasing resource utilization by 60%;

- Data: Through modular design, the average service cycle of a new energy pole piece equipment extended from 5 years to 8 years, with full-life cycle carbon emissions decreasing by 37%.

▶ 3. Lightweight Design: Achieving “Energy Conservation and Material Reduction” through “Structural Optimization”

- Technical Means:

- Topology optimization (Altair HyperWorks): Reduces robotic arm base material by 30% without compromising strength (improving stress distribution uniformity by 25%);

- 3D printed custom parts: An 非标 fixture printed via SLM reduces weight from 12kg to 5kg, increasing material utilization from 35% to 90%;

- Benefits: After lightweighting, the motor power of a hardware stamping line decreased from 75kW to 55kW, saving 150,000 kWh annually and reducing equipment transportation carbon emissions by 40%.

II. Energy Consumption Optimization: Technological Revolution from “Extensive Power Use” to “Intelligent Energy Saving”

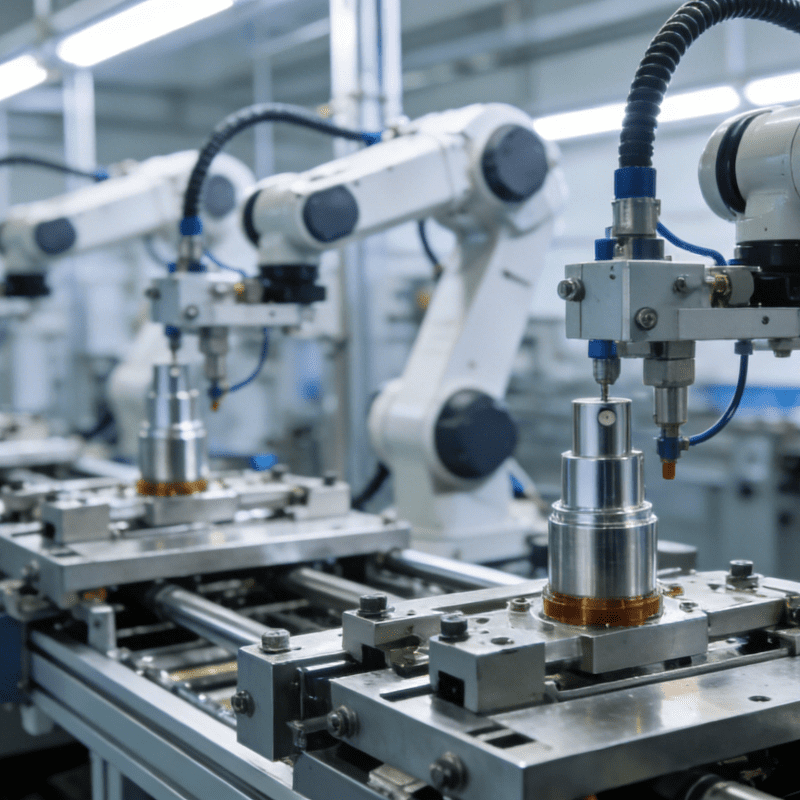

▶ 1. Power System Energy Saving: “Dual-Drive” of Servo Drive + Energy Recovery

- Servo Motor Upgrades:

- Adopting IE4 ultra-high efficiency servos (e.g., Panasonic MINAS A6, efficiency 96% vs. 88% for traditional IE2 motors), reducing the power of a lithium battery laminator from 45kW to 32kW, saving 130,000 kWh annually;

- Vector control algorithm: Dynamically adjusts current based on load (e.g., 30% current reduction under no-load), reducing the energy consumption fluctuation coefficient of a 3C mounter from 0.7 to 0.3 (closer to 0 means more energy-saving).

- Energy Recovery System:

- Servo braking energy is fed back to the power grid via a converter (70% recovery rate), with an auto welding line recovering 80,000 kWh annually, equivalent to the annual electricity consumption of 40 households;

- The hydraulic system switches to a variable frequency oil pump, reducing flow to 10% during standby, decreasing standby energy consumption of a die-casting machine from 20kW·h to 3kW·h.

▶ 2. Intelligent Energy Efficiency Management: AI+IoT Builds an “Energy Consumption Digital Twin”

- Technical Architecture:

- Sensors collect over 20 parameters such as voltage, current, and power factor in real-time, with edge computing boxes (e.g., Advantech UNO-3082) generating energy consumption heat maps;

- AI algorithms (LSTM model) predict energy consumption peaks and adjust production plans in advance (e.g., off-peak power usage, saving 15% on electricity prices);

- Case: After deploying an energy efficiency management system, a bearing factory increased equipment OEE by 12%, reduced energy consumption by 18%, and saved 450,000 RMB in annual electricity costs.

▶ 3. Heat Dissipation and Insulation: Reducing “Invisible Energy Consumption” Losses

- Heat Dissipation Optimization:

- Servo drives use liquid cooling (temperature rise ≤25℃), 40% more efficient than air cooling, with fan energy consumption reduced to 0;

- Electrical control cabinets incorporate phase-change materials (melting point 45℃), absorbing heat and storing energy at high temperatures, reducing air conditioning operation time by 30%;

- Data: After improving heat dissipation for a non-standard testing equipment, the workshop air conditioning load decreased by 20kW, saving 80,000 RMB in summer electricity costs annually.

III. Full Life Cycle Management: A Closed-Loop Ecosystem from “Equipment Manufacturing” to “Recycling and Regeneration”

▶ 1. Design Stage: Embedding Genes of “Maintainability and Recyclability”

- Maintainable Design:

- Key components reserve quick-replacement interfaces (e.g., fool-proof design for servo motor plugs, reducing replacement time from 2 hours to 20 minutes);

- Fault code coverage ≥95%, with a bending machine allowing maintenance manual access via QR code scanning, improving after-sales efficiency by 60%;

- Recyclable Design:

- Material classification labeling (e.g., casing marked “ABS+PC”), improving disassembly efficiency by 50% at the end of life;

- Modular connections (bolted vs. welded), with 90% of parts from a new energy equipment reusable after disassembly.

▶ 2. Operation and Maintenance Stage: Predictive Maintenance + Green Maintenance

- Predictive Maintenance:

- Vibration sensors (precision ±0.1mm/s) monitor bearing status, warning of wear 7 days in advance (traditional periodic replacement wastes 30% of service life);

- Oil analysis (infrared spectroscopy) predicts hydraulic oil replacement cycles, extending the maintenance cycle of a die-casting machine from 3 months to 6 months, reducing consumable costs by 50%;

- Green Maintenance:

- Using biodegradable lubricating oil (e.g., ester oil, degradation rate ≥90%), a food equipment avoids oil pollution, reducing environmental fines to 0.

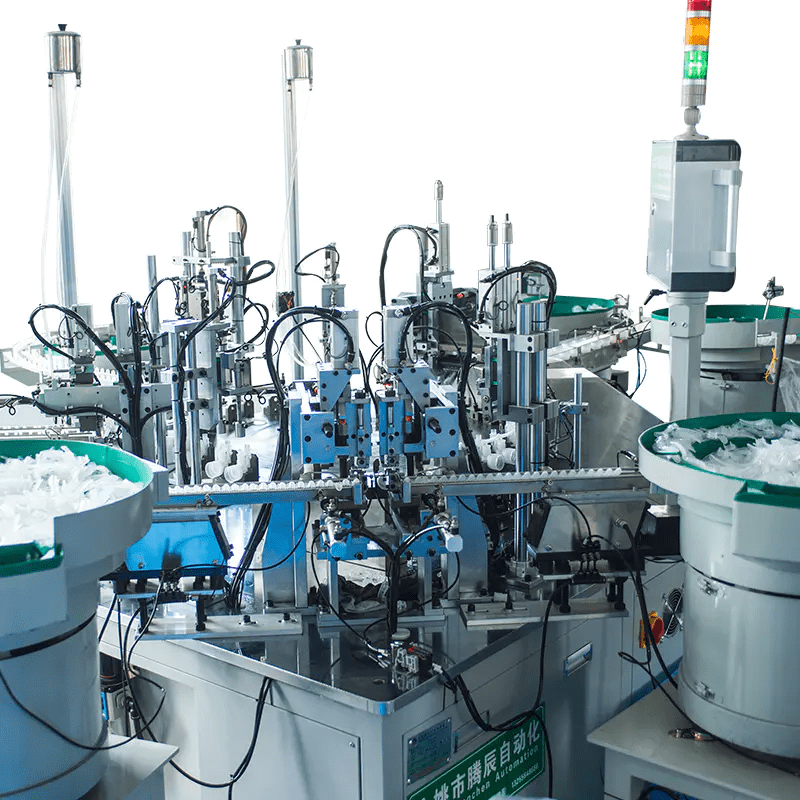

▶ 3. Disposal Stage: Building a “Regeneration-Remanufacturing” Industrial Chain

- Remanufacturing Process:

Disassembly and cleaning (ultrasonic + dry ice cleaning, pollutant removal rate 99%);

ii. Key component detection (3D scanning precision ±0.01mm, screening reusable parts);

iii. Functional repair (e.g., motor rotor rewinding, cost only 30% of new products); - Case: The remanufactured servo motors of an automation manufacturer achieve 95% of new product performance, 40% lower price, 75% reduced carbon footprint, and annual recycling of 1,000 units.

IV. Industry Compliance: “Survival Strategies” for Global Environmental Regulations

▶ 1. Carbon Tariff Response: From “Passive Tax Payment” to “Active Carbon Reduction”

- Tools:

- ISO 14064 carbon footprint accounting, reducing full-life cycle carbon emissions of a device from 820tCO₂ to 510tCO₂, lowering carbon tariff costs by 38%;

- Purchasing green electricity (e.g., photovoltaic power), with a 3C enterprise’s 30% green power share obtaining a 15% carbon tariff reduction for export products;

- Data: After the EU CBAM implementation, equipment exports with carbon footprint optimization grew by 22%, while exports of unoptimized enterprises dropped by 18%.

▶ 2. E-Waste Management: Design Complying with WEEE Directive

- Requirements:

- Equipment marked with a “trash bin” symbol indicating recyclability;

- Harmful substances (e.g., lead, mercury) content ≤0.1% (RoHS 3.0 standard);

- Case: A medical device manufacturer was fined 200,000 euros by the EU for using brominated flame retardants in equipment. After switching to halogen-free materials, it not only complied with regulations but also entered the Nordic green procurement list.

▶ 3. Energy Efficiency Label System: Obtaining “Passports” for Market Access

- Certifications:

- China Energy Efficiency Label (e.g., equipment energy efficiency grade ≥2);

- EU Ecodesign Directive (standby power consumption ≤1W);

- Impact: After passing energy efficiency certification, a non-standard grinding machine entered the government green procurement catalog, with order volume increasing by 30%.

V. Future Trends: Three Breakthrough Directions for Sustainable Technologies

▶ 1. Hydrogen Energy Power: The “Zero-Carbon Heart” of Non-Standard Equipment

- Progress: Toyota’s hydrogen fuel cells have been piloted in logistics warehousing robots, with a 10-hour battery life (4 hours for traditional lithium batteries), 3-minute hydrogen refueling, and zero carbon emissions;

- Scenario: A non-standard sorting line in a food factory using hydrogen energy drive avoids lithium battery pollution risks, complying with FDA environmental requirements.

▶ 2. Digital Twin Optimization: Virtual Debugging Reduces “Physical Waste”

- Value: Simulating 1,000 working conditions in the digital twin to optimize equipment energy consumption parameters, a new energy equipment reduced 15 physical prototype iterations during debugging, saving 3 tons of steel and reducing energy consumption test power by 80%.

▶ 3. Blockchain Traceability: Building a “Green Supply Chain” Trust System

- Application: Blockchain records full-life cycle data of equipment (e.g., recycled aluminum usage ratio, energy consumption optimization records), with an auto manufacturer obtaining a 12% EU carbon tariff reduction by proving equipment carbon footprint through blockchain.

VI. The “ROI Formula” of Sustainable Development: Environmental Protection Investment ≠ Increased Costs

Traditional perception holds that “environmental protection” implies “high investment,” but actual data shows:

- A 3C enterprise invested 2 million RMB in green transformation, saving 250,000 kWh annually (180,000 RMB in electricity costs) + 220,000 RMB in carbon tariff reductions, recovering costs in 1.8 years, with annual net profits of 400,000 RMB thereafter;

- Non-standard equipment using recycled materials has only a 5% increase in manufacturing costs, but due to compliance with green procurement standards, the selling price can increase by 10%, with profit margins rising by 3 percentage points.

This confirms the new logic of sustainable development: in an era of stricter environmental regulations and high energy costs, green non-standard equipment is not a “moral choice” but an “economic necessity.”

Conclusion: When Non-Standard Equipment “Can Plant Trees”

From recycled aluminum frames to hydrogen energy drives, from energy consumption digital twins to blockchain traceability, non-standard automation equipment is transforming from an “industrial energy consumer” to a “green practitioner.” Under the carbon neutrality goal, only by integrating sustainable development into the “genetic design” of equipment can non-standard equipment not only solve production challenges but also address environmental dilemmas — when a stamping machine can “virtually plant” 100 trees through energy recovery while producing efficiently, industrial manufacturing will truly move towards a sustainable future.

(Next Preview: “Global Opportunities and Challenges of Non-Standard Automation Equipment: Key Points for Cross-Border Project Implementation and Localization Adaptation Strategies”, analyzing technical barriers, cultural differences, and compliance challenges faced by Chinese non-standard equipment when going global, providing a full-process cross-border guide from solution design to after-sales service.)