In industries such as electronic components, automotive precision parts, and hardware accessories, small metal sheets (e.g., micro-contacts, stamping gaskets, and chip lead frames) with a thickness of 0.1-5mm and a size of 5-100mm are core basic components. In the production and processing of these parts, the “feeding” process may seem simple, but it is a key bottleneck restricting efficiency and precision. Traditional manual feeding is not only inefficient and prone to safety accidents but also far from meeting the requirements of “zero error and high consistency” in precision manufacturing. The emergence of Automatic Feeding Equipment for Small Metal Sheets (hereinafter referred to as “automatic metal sheet feeder”)—with its technical combination of “automation + precision + flexibility”—has become the core equipment to bridge the “last meter” of precision manufacturing production lines.

Industry Pain Points: Why Do Traditional Feeding Methods “Hold Back Progress”?

The physical characteristics (thin, small, and easy to deform) of small metal sheets and manufacturing requirements (high precision, high cleanliness) have exposed the limitations of traditional feeding methods, which can be summarized into three major pain points:

- Manual Feeding: Low Efficiency, Poor Precision, and High Risks

Efficiency Bottleneck: Manual single-piece grabbing, positioning, and placing of small metal sheets usually only reach a speed of 30-50 pieces per minute. Moreover, long-term operation leads to fatigue, resulting in a continuous decline in efficiency. If the metal sheets have burrs or sharp edges, manual operation requires extra caution, further slowing down the pace.

Precision Loss: During manual placement, the positional deviation of parts often reaches 0.5-1mm. However, scenarios such as electronic component welding and automotive precision stamping require part positioning accuracy within ±0.05mm. Such deviations directly increase the product scrap rate (exceeding 10% in some scenarios).

Safety and Cost Risks: Small metal sheets are mostly used with equipment such as stamping machines and laser cutting machines. During manual feeding, hands are prone to entering the equipment’s working area, posing risks of crushing and cutting. Meanwhile, labor costs rise year by year—a single production line requires 2-3 feeding workers, with annual labor costs exceeding 150,000 yuan.

- Simple Mechanical Feeding: Insufficient Flexibility and Poor Adaptability

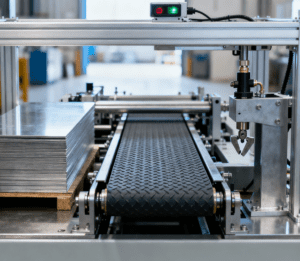

Some enterprises use simple mechanical feeding equipment such as vibratory bowls and belt conveyors, which can replace part of manual work but are “incompatible” when facing metal sheets of multiple types and specifications:

Vibratory bowls easily scratch or stack thin metal sheets (thickness < 0.3mm). Additionally, adjusting the vibration frequency and track size during model change takes 1-2 hours per change.

Belt conveyors cannot achieve precise positioning; parts still require manual secondary calibration after reaching the workstation, making true “unmanned operation” impossible.

- Difficulties in Cleanliness and Consistency

In fields with high cleanliness requirements such as semiconductors and medical equipment, sweat and dust from manual feeding can contaminate the surface of metal sheets. Friction and collision in traditional mechanical feeding can cause the coating on the part surface to peel off, affecting subsequent processing quality. Furthermore, uneven force during manual feeding can lead to micro-deformation of metal sheets (invisible to the naked eye), ultimately affecting product performance.

Technical Breakdown: The “Four Core Modules” of Automatic Metal Sheet Feeder

A high-quality automatic metal sheet feeder is not a simple “mechanical handling device” but an integrated system combining “material storage – precision conveying – visual positioning – intelligent control”. The four core modules jointly ensure “fast, accurate, and stable” feeding:

- Flexible Material Hopper: Adapting to Multiple Specifications and Protecting Materials

The material hopper serves as the “material reserve” of the equipment, requiring a balance between storage capacity and material protection:

Layered Hopper: For metal sheets of different thicknesses (0.1-5mm), adjustable layered partitions are used to avoid deformation caused by stacking pressure. Some equipment is also equipped with “scratch-resistant coatings” (e.g., polytetrafluoroethylene) to reduce friction between metal sheets and the inner wall of the hopper.

Automatic Material Replenishment: The hopper has a built-in infrared sensor. When the remaining material is below the threshold (e.g., 100 pieces), it automatically triggers a material replenishment signal and can be linked with an external material rack to achieve “uninterrupted feeding”, avoiding production line shutdowns.

Adaptive Design: For roll-shaped small metal sheets (e.g., chip lead frames), the hopper can be equipped with a “unwinding tension control system” to precisely control the unwinding speed and prevent stretching or wrinkling of metal sheets. For sheet materials, “vacuum suction cup picking” is used instead of mechanical grabbing to reduce contact damage.

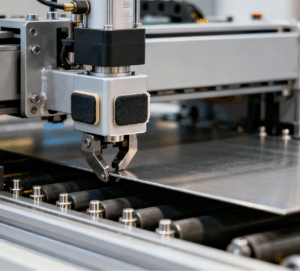

- Precision Conveying Mechanism: The Key to Controlling “Speed and Precision”

The conveying mechanism acts as a “bridge” connecting the material hopper and processing workstations, and the appropriate conveying method is selected based on the characteristics of metal sheets:

Vacuum Suction Conveyor Belt: Suitable for thin, lightweight metal sheets (thickness < 0.5mm). The conveyor belt surface is distributed with micro-suction holes, which adsorb metal sheets through negative pressure to avoid deviation or slipping during conveying. The conveying speed can reach 120-150 pieces per minute, with a positioning accuracy of ±0.03mm.

Roller Conveying: For rigid metal sheets with a thickness of 1-5mm, a synchronous roller set (with a rubber anti-slip layer on the surface) is used. The rotation speed of the rollers is controlled by a servo motor to achieve uniform-speed conveying while avoiding scratches on the metal sheet surface.

Linear Module Conveying: Used in high-precision scenarios (e.g., semiconductor packaging). A linear motor drives the picking suction cup, achieving a positioning accuracy of ±0.02mm and a smooth movement trajectory to reduce vibration of metal sheets.

- Visual Positioning and Detection Module: The “Eyes” and “Quality Inspector”

The visual system is the core of the equipment to achieve “precision feeding”, usually composed of an industrial camera, light source, and image processing algorithm:

Positioning Function: The camera captures the feature points of the metal sheet (e.g., hole positions, edges), compares them with the preset standard image, calculates the positional deviation, and adjusts the conveying mechanism through the servo system to ensure the deviation of the metal sheet when reaching the workstation is ≤ ±0.05mm.

Defect Detection: It synchronously detects whether the metal sheet surface has scratches, oil stains, deformation, etc., with a detection accuracy of over 99.5%. Unqualified products are automatically sorted into the waste box to prevent them from entering subsequent processes.

Specification Recognition: For multi-variety production lines, the visual system can automatically identify the size and shape of metal sheets without manual parameter switching. The model change time is shortened to 5-10 minutes (compared to over 1 hour with traditional methods).

- Intelligent Control System: The “Brain” of the Equipment

The control system integrates the collaborative work of the material hopper, conveying mechanism, and visual system, with core functions including:

Parameter Visualization Setting: Parameters such as feeding speed, positioning accuracy, and detection standards can be set through a touch screen. It supports storing process parameters for more than 100 types of metal sheets, which can be directly called for subsequent use.

Linkage Control: It communicates in real-time with downstream processing equipment (e.g., stamping machines, laser welders) and automatically adjusts the feeding speed according to the rhythm of downstream equipment to avoid “excessive feeding” or “insufficient feeding”.

Data Traceability: It records data such as the feeding quantity, qualified quantity, and defect type of each batch of metal sheets, and can be connected to the MES system to achieve full-process production traceability and meet quality control requirements.

Scene Implementation: Covering Precision Manufacturing in Multiple Industries from “Electronics” to “Automotive”

By adapting to the “thin, small, and precise” characteristics of small metal sheets, the automatic feeder has been deeply implemented in multiple segmented fields, becoming the key to improving production line efficiency and reducing costs:

- Electronic Components Industry: Feeding of Micro Metal Contacts

In the welding scenario of metal contacts (size 5×3mm, thickness 0.2mm) for mobile phone camera modules, manual feeding easily causes contact deviation, resulting in a welding yield of only 85%. After an electronic manufacturer introduced the automatic feeder, through vacuum suction conveying + visual positioning, the contact positioning accuracy was controlled within ±0.03mm, the welding yield was increased to 99.2%, and the feeding speed was raised from 40 pieces per minute (manual) to 120 pieces per minute. A single production line reduced 2 workers, saving over 200,000 yuan in annual labor costs.

- Automotive Precision Parts Industry: Feeding of Stamping Gaskets

Precision stamping gaskets (size 20×15mm, thickness 1mm) for automotive gearboxes require continuous processing with stamping machines. Traditional vibratory bowl feeding is prone to sheet stacking, causing stamping machine jams with a shutdown rate of over 5%. After adopting the automatic feeder, through layered hopper + roller conveying, “single-sheet separation and uniform-speed feeding” was achieved. The stamping machine shutdown rate was reduced to below 0.3%, the daily output was increased from 8,000 pieces to 15,000 pieces, and scratches on the gasket surface were avoided, raising the product qualification rate to 99.8%.

- Semiconductor Industry: Feeding of Chip Lead Frames

The packaging process of chip lead frames (thickness 0.15mm, with precision holes) has extremely high requirements for cleanliness and positioning accuracy. The automatic feeder adopts “dust-free hopper + linear module conveying”, maintaining Class 1000 cleanliness in the hopper and achieving a visual positioning accuracy of ±0.02mm. It not only avoids manual contamination but also increases the packaging yield from 92% to 99.5%. Meanwhile, it supports quick model changes for 8 different specifications of lead frames, meeting the “multi-variety, small-batch” production needs of the semiconductor industry.

- Hardware Accessories Industry: Feeding of Small-Specification Spring Sheets

In the production of micro spring sheets (size 8×5mm, thickness 0.3mm) in the hardware industry, improper force during manual feeding easily causes spring sheet deformation, with a scrap rate of over 8%. The automatic feeder uses “flexible vacuum suction cups” for picking and matches visual detection for deformation defects, reducing the spring sheet scrap rate to 1.2% and increasing feeding efficiency by 3 times. A single production line saves over 120,000 yuan in annual costs.

Technological Breakthroughs: Solving Long-Standing Industry Problems

In response to the special challenges of small metal sheet feeding, the automatic feeder has achieved multiple breakthroughs through technological innovation:

Deformation Prevention for Thin Sheets: “Low negative pressure vacuum adsorption” (with adjustable negative pressure value) is adopted. For ultra-thin metal sheets of 0.1mm, the negative pressure is controlled at -30kPa, ensuring firm adsorption while avoiding deformation caused by excessive extrusion.

Quick Model Change for Multiple Specifications: The spacing of hopper partitions and conveying rollers is automatically adjusted by servo motors, and the visual system automatically identifies part specifications. No manual disassembly or replacement of components is required, shortening the model change time to within 5 minutes.

Surface Cleanliness Protection: The hopper and conveying mechanism adopt a “non-contact design” (e.g., suspended conveyor belt) to reduce friction between metal sheets and equipment. Some equipment is also equipped with an “ion wind dust removal module” to remove static electricity and dust from the metal sheet surface, meeting cleanliness requirements.

Future Trends: Upgrading to “More Intelligent and Flexible”

As precision manufacturing transitions to “customization and multi-variety”, the development of automatic metal sheet feeders will show three major trends:

AI Visual Optimization: AI algorithms are introduced to improve the recognition speed and accuracy of the visual system. Even if metal sheets have slight wear or stains, precise positioning can still be achieved. At the same time, “automatic defect type classification” (e.g., scratches, deformation) is realized to provide data support for production process optimization.

Modular Design: The equipment adopts a modular structure. The material hopper, conveying mechanism, and visual system can be freely combined according to needs. For example, for roll-shaped metal sheets, an integrated “automatic cutting + feeding” module can be matched to further simplify the production line process.

Digital Twin Linkage: It is connected to the factory digital twin platform. Through virtual simulation, the feeding process of different metal sheets is simulated, and parameters (e.g., conveying speed, negative pressure value) are optimized in advance to reduce on-site debugging time. At the same time, the equipment operation status is monitored in real-time to achieve predictive maintenance and reduce failure rates.

Conclusion: More Than “Feeding”, It Is the “Efficiency Cornerstone” of Precision Manufacturing

The value of the automatic small metal sheet feeder goes far beyond replacing manual labor. It reduces product scrap rates through “precision control”, meets multi-variety production needs through “flexible adaptation”, and ensures quality control through “data traceability”, becoming the infrastructure supporting the upgrade of precision manufacturing to “higher efficiency and higher quality”.

From micro-contacts of electronic components to precision gaskets of automotive gearboxes, and to lead frames of semiconductors, this “feeding revolution” is reshaping the production logic of precision manufacturing. When “fast, accurate, and stable” feeding becomes the norm, enterprises can focus more energy on core technological innovation—and this is the core path of “cost reduction, efficiency improvement, and quality upgrading” in the era of intelligent manufacturing.