In the core of agricultural production, seeding precision directly determines crop emergence rate, growth uniformity, and final yield. Among these factors, the stability of seed depth is crucial—excessively deep sowing may hinder germination, while overly shallow placement leaves seeds vulnerable to drought or low temperatures. For a long time, the industry has relied on hydraulic, pneumatic, or mechanical spring systems to control seeding downforce. However, in high-speed seeding scenarios, these technologies have consistently faced bottlenecks such as poor consistency, high costs, or complex maintenance. Today, an intelligent electric damper based on magnetorheological technology is rewriting this situation, bringing a revolutionary breakthrough to precision agriculture.

Dilemma of Existing Technologies: The “Precision Shortcoming” in High-Speed Seeding

Over the past decade, hydraulic and pneumatic downforce systems have led technological upgrades in seeding depth control. Hydraulic systems, with their advantages of independent row adjustment and fast response, have become the first choice for high-precision scenarios; pneumatic systems, characterized by group control and easy adjustability, are widely used in large-scale farming. Both have significantly improved seeding efficiency, promoted uniformity in crop harvest timing, and thereby increased yields.

However, their pain points are equally prominent: Hydraulic systems require multiple pipelines for each seeding row unit. A 36-row seeder, for example, can have over 100 connection points, which is not only labor-intensive to install but also plagued by leakage risks at folding or latching parts—an ongoing headache for farmers. Pneumatic systems, though structurally simpler, struggle to achieve precise single-row control and perform poorly in fields with complex soil conditions. Mechanical springs, which rely entirely on preset force and cannot adapt to dynamic changes in soil resistance during high-speed seeding, have long been phased out by mainstream manufacturers.

Technological Breakthrough of Electric Dampers: “Intelligent Response” of Magnetorheological Fluids

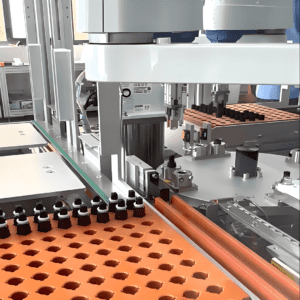

The core of intelligent electric dampers (also known as magnetorheological dampers) lies in their special magnetorheological (MR) fluid—a material composed of magnetic particles suspended in a carrier liquid. It can change state within milliseconds in response to magnetic field intensity: liquid without a magnetic field, and instantly transforming into a semi-solid state under a magnetic field, with viscosity proportional to the field strength.

In seeders, the damper works in synergy with a vehicle speed sensor and a force feedback sensor: When the sensors detect changes in soil resistance or increased vehicle speed, the control system adjusts the current in the electromagnetic coil inside the piston to real-time modify the viscosity of the MR fluid, thereby dynamically regulating the damper’s resistance. This response speed allows the seeding unit to quickly counteract upward impacts from soil bulges or stones during high-speed operation (typically over 10 km/h), maintaining stable furrow depth.

Compared with traditional systems, its advantages are significant: No complex pipelines are needed—single-row installation only requires simple electrical connections, almost eliminating leakage risks; costs are reduced by over 30% compared to hydraulic systems; and through dual-parameter control of force feedback and vehicle speed, seed depth deviation can be controlled within ±5 mm in fields with uniform soil types, far outperforming the ±10 mm of hydraulic systems.

Field Test Verification: “Stability Dominance” in High-Speed Scenarios

In comparative tests on dry land, seeding units equipped with electric dampers showed clear advantages: Compared with spring systems, the fluctuation range of furrow depth was reduced by 60%, and the vibration frequency of row units decreased by 45%; even when the speed was increased to 1.5 times that of traditional hydraulic systems, depth stability was maintained.

Tests also found that correlating vehicle speed with damper stiffness yielded better results—when speed increased from 8 km/h to 12 km/h, the system automatically increased damping resistance to counteract the “floating soil” tendency caused by inertia. Researchers note that this feature makes it particularly suitable for large-scale planting areas: In plains and fields with uniform soil texture, farmers can increase daily seeding area (from the traditional 200 mu to over 300 mu) through high-speed operation while ensuring consistent emergence.

Future Outlook: From Technological Breakthrough to Industrial Implementation

Although current tests are still limited to single soil types, and further verification in heavy clay or stony fields is needed, the industry generally believes that the commercialization of electric dampers is imminent. Their simple structure, controllable costs, and strong adaptability make them especially suitable for upgrading small and medium-sized farms. Moreover, integration with autonomous seeders may open up new scenarios of “unmanned precision seeding.”

From a broader perspective, the breakthrough of electric dampers is not only a technological innovation but also a microcosm of “cost reduction and efficiency improvement” in smart agriculture—through the integration of materials science and sensing technology, high-end precision agricultural technologies are no longer exclusive to large farms but become inclusive productivity tools. Perhaps in the near future, when we discuss agricultural yield improvement, this technology “hidden under the seeder” will become an indispensable key variable.