As industrial manufacturing moves towards intelligence and high-endization, the performance of precision components directly determines the reliability and competitiveness of products. As a core technology in modern manufacturing, CNC precision machining is characterized by high precision, high efficiency, and high consistency, and is providing solid technical support for fields such as automotive, aerospace, electronic equipment, and industrial machinery. We specialize in the field of CNC precision machining, with advanced equipment, mature processes, and strict quality control as the core, providing customers with full-process solutions from design to mass production, helping products achieve stable performance in complex application scenarios.

Anchoring on Technology, Defining New Standards for Precision

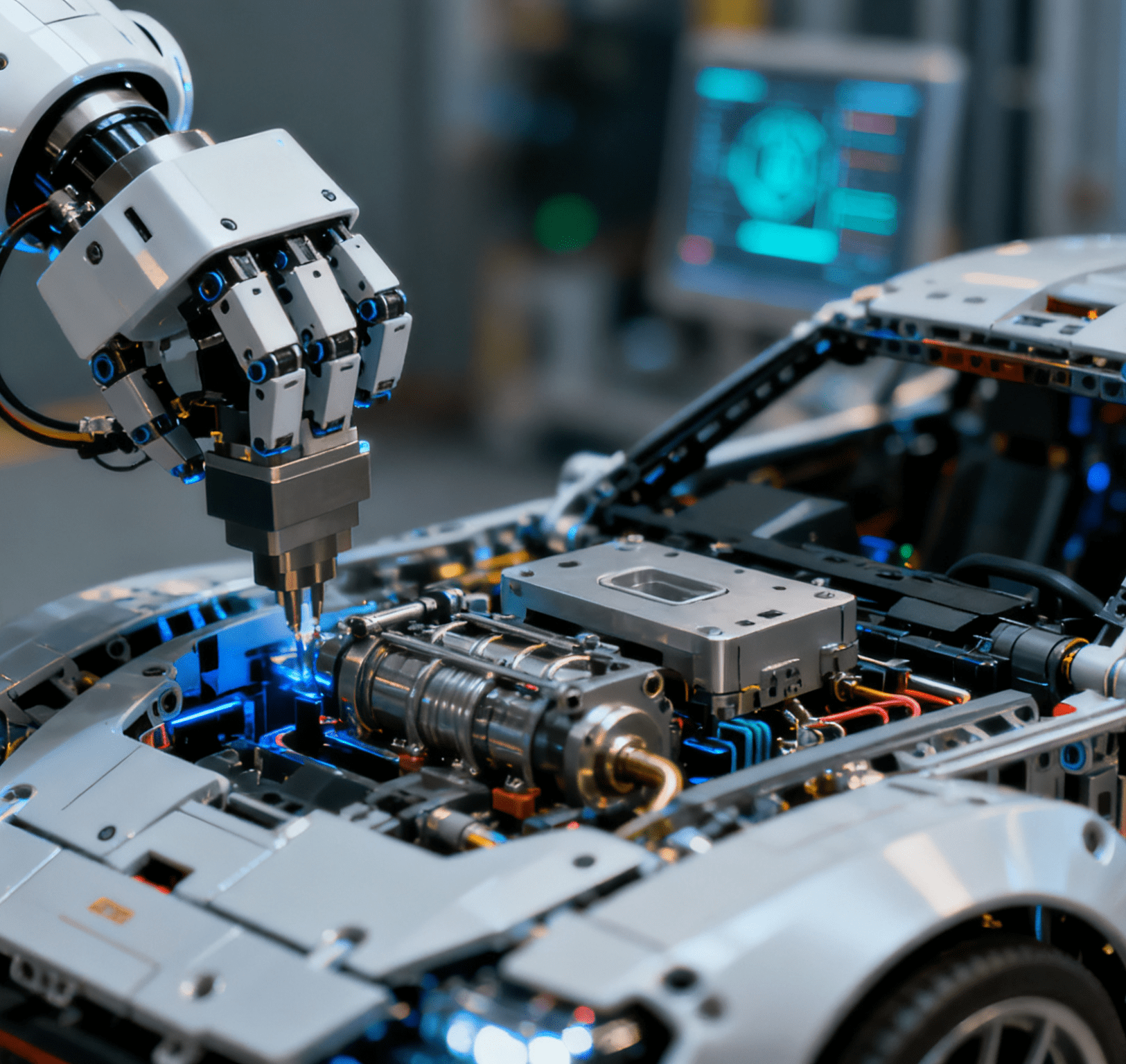

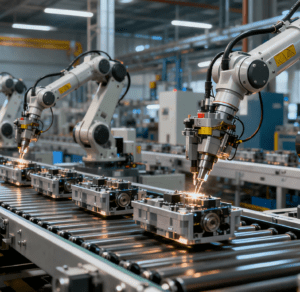

The core value of CNC precision machining lies in achieving precise forming of complex structures through digital control. Whether it is the micron-level tolerance of micro-components or the high consistency requirements of large workpieces, it relies on the in-depth integration of equipment precision, process optimization, and operational experience. We adopt high-performance CNC machine tools and multi-axis linkage machining technology, combined with intelligent programming systems, to ensure the machining stability of key features such as complex curved surfaces, precision holes, and thin-walled structures. In response to the needs of different industries for material hardness, corrosion resistance, lightweight and other characteristics, we continuously optimize cutting parameters and machining strategies, achieving a dynamic balance between efficiency and precision, and laying the foundation for the high-performance of components.

Multi-Field Adaptation, Empowering Industrial Upgrading

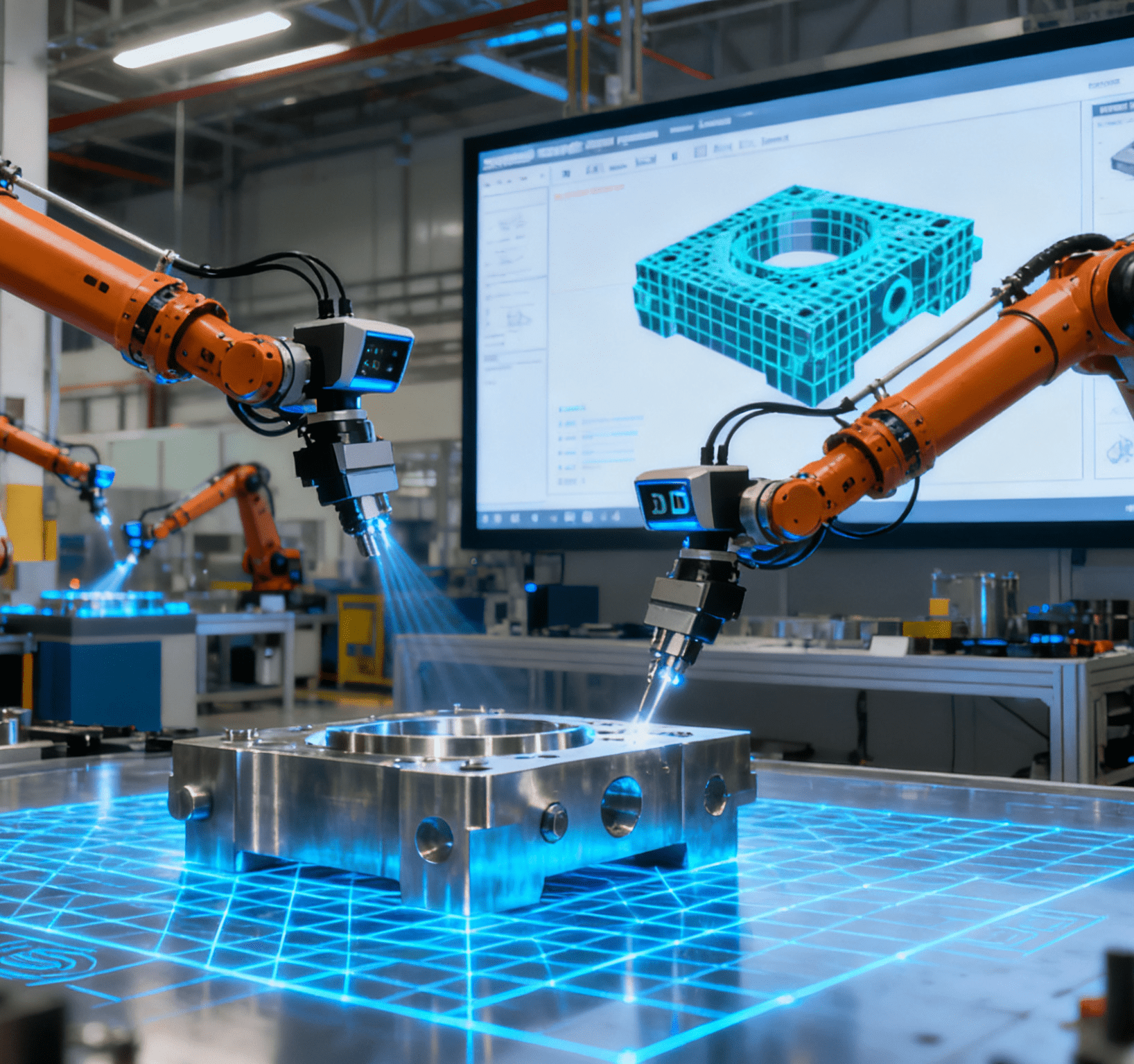

The value of CNC precision machining lies not only in the technology itself but also in its adaptability to diverse scenarios. From core components of automotive power systems to precision structural parts of electronic equipment, from high-load transmission parts of industrial machinery to customized functional components, we deeply understand the application logic and technical pain points of different industries and provide targeted solutions. For diversified materials such as metals, engineering plastics, and composite materials, we have established a comprehensive process database. Through material property analysis and machining simulation, we avoid potential risks such as deformation, burrs, and stress concentration. At the same time, we actively explore process innovations for difficult-to-machine materials and special structural parts, helping customers iterate their products through technological breakthroughs.

Full-Process Quality Control, Safeguarding Manufacturing Reliability

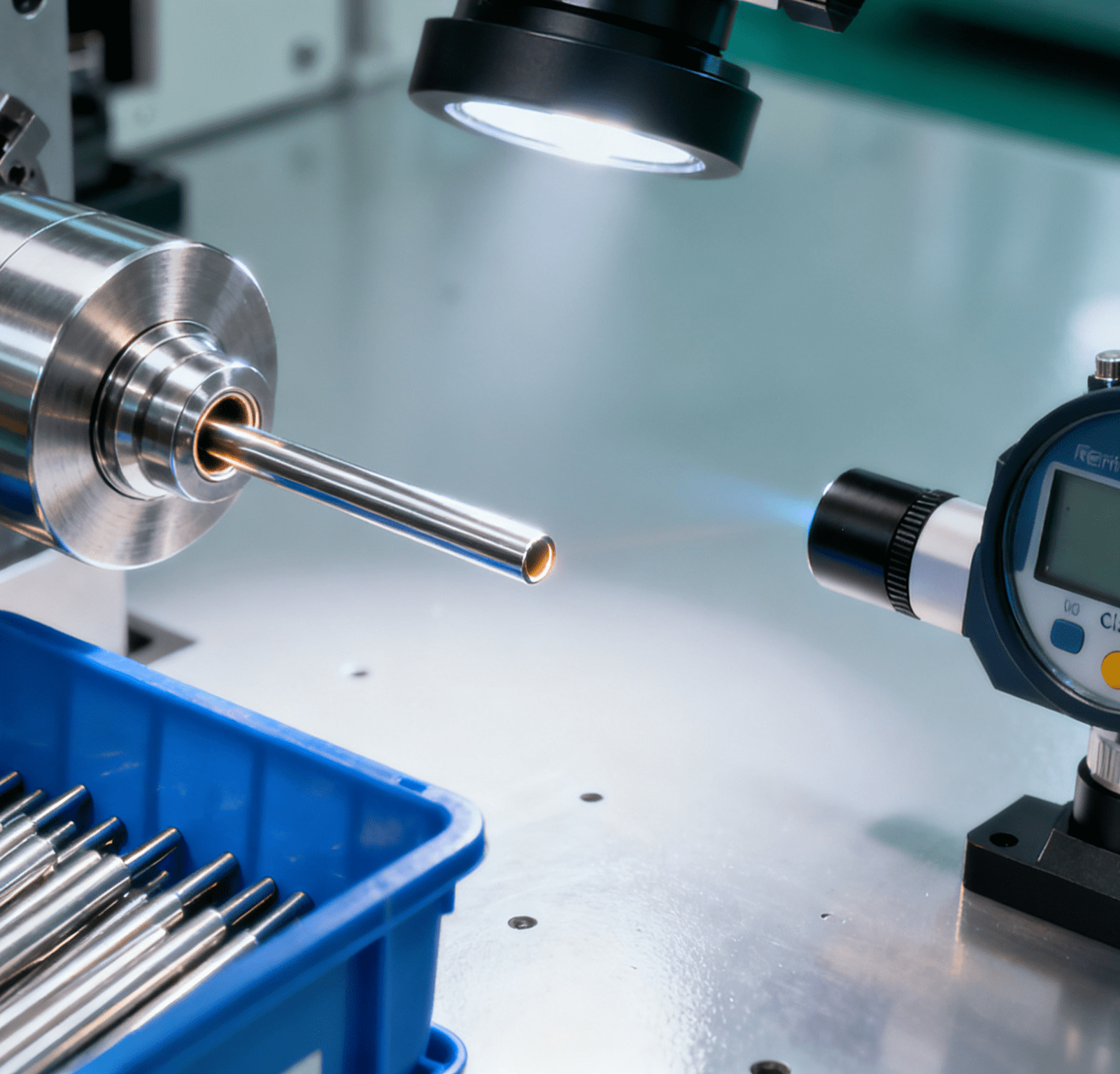

The essence of precision machining is “maintaining certainty throughout the process”. We have built a full-process quality control system from incoming material inspection to final product inspection. Using high-precision coordinate measuring machines, optical inspection equipment, and surface roughness analyzers, we conduct multi-dimensional verification of key indicators such as dimensional tolerance, geometric accuracy, and surface integrity. In the production process, we strictly follow standardized operating procedures, combined with equipment status monitoring and process parameter traceability systems, to ensure the controllability of the machining process and the consistency of results. In addition, we continuously improve the quality management system, converting industry standards into implementable execution norms through internal audits and external certifications, providing customers with reliable delivery guarantees.

Flexible Production, Responding to Agile Needs

Facing the market trends of small-batch customization and rapid iteration, the value of CNC precision machining is extending from “large-scale production” to “agile services”. Through modular production line planning and flexible manufacturing systems, we realize seamless connection from prototype trial production to mass production—our integrated Universaali kokoonpanojärjestelmä supports quick adaptation to precision components of different specifications and sizes, enabling tool-free changeover within 15 minutes and ensuring consistent assembly accuracy even for customized orders with diverse requirements. For customers’ design drawings, we provide process feasibility analysis and cost optimization suggestions to help shorten the R&D cycle; in the mass production stage, we ensure on-time delivery of orders through intelligent scheduling and supply chain collaborative management. Whether it is emergency demand response or long-term strategic cooperation, we always take customer needs as the guide and find the best balance between quality and efficiency.

Green Intelligent Manufacturing, Practicing the Concept of Sustainability

While pursuing technological advancement, we are committed to reducing resource consumption and environmental load in the manufacturing process. We realize the green upgrading of the production process through measures such as optimizing machining paths to reduce energy consumption, adopting environmentally friendly cutting fluids and cooling systems, and implementing classified recycling of waste chips. We believe that precision machining not only requires technological leadership but also needs to assume responsibility for the industry and the environment. In the future, we will continue to explore the integration path of energy conservation and emission reduction with process innovation, providing customers with solutions that combine economic value and ecological benefits.

Working Together to Explore New Frontiers of Intelligent Manufacturing

CNC precision machining is a craft that requires continuous in-depth cultivation. It relies not only on the hard power of equipment and technology but also on the soft power of experience accumulation and lean management. We always treat each product with awe and interpret the weight of the word “precision” with professional capabilities. If you are looking for a partner who can understand your needs and deliver accurately, we look forward to in-depth communication with you. Let us take technology as a bridge to jointly promote the progress of the high-end manufacturing field and inject lasting momentum into industrial upgrading.