In fields such as precision mechanical machining, CNC precision machining, and medical component machining, precision grinding is an extremely important process, as it is directly related to the precision and surface quality of products. To achieve the desired grinding effect, optimizing process parameters is the key. Below is an in-depth understanding of knowledge in this area.

Grinding Wheel Speed: Balancing Speed and Precision

Grinding wheel speed is one of the key parameters in precision grinding. In CNC machining, an appropriate grinding wheel speed can effectively improve grinding efficiency and surface quality. When the speed is too low, the frictional effect between the grinding wheel and the workpiece weakens, resulting in low grinding efficiency, and may cause scratches on the workpiece surface and increased roughness. On the contrary, although a too-high grinding wheel speed can improve grinding efficiency, it will cause the grinding temperature to rise sharply, which may lead to problems such as workpiece burning and deformation, affecting machining precision. For example, in medical component machining, excessively high temperatures may change the metallographic structure of parts and reduce their performance. Therefore, it is necessary to reasonably select the grinding wheel speed based on factors such as workpiece material and grinding wheel characteristics, and find the optimal balance between efficiency and precision.

Feed Rate: Minor Adjustments Bring Significant Changes

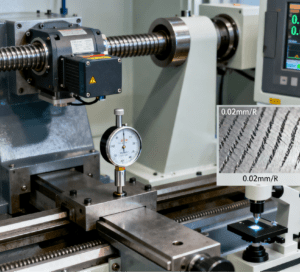

The impact of feed rate on precision grinding should not be underestimated. In mold machining, a smaller feed rate allows the grinding wheel to leave finer grinding marks on the workpiece surface, thereby obtaining a smoother surface. However, an excessively small feed rate will greatly extend the machining time and reduce production efficiency. Although a larger feed rate can improve machining efficiency, it may increase the grinding force, leading to higher surface roughness of the workpiece and even dimensional deviations. Therefore, it is necessary to determine the appropriate feed rate through multiple tests according to specific machining requirements, so as to achieve the goal of efficient and high-quality machining.

Grinding Depth: Precise Control Ensures Quality

Grinding depth is also an important parameter affecting precision grinding. In CNC precision machining, an excessively deep grinding depth will cause a sharp increase in grinding force and grinding heat, which not only easily leads to defects such as workpiece surface burning and cracks, but also may accelerate grinding wheel wear, affecting machining precision and grinding wheel service life. On the contrary, an excessively shallow grinding depth cannot give full play to the grinding performance of the grinding wheel, resulting in low machining efficiency. Therefore, in the actual machining process, it is necessary to precisely control the grinding depth according to the workpiece material, hardness, and machining precision requirements to ensure the stability of machining quality.

Cooling and Lubrication: An Indispensable Auxiliary Factor

Cooling and lubrication play a crucial role in precision grinding. In Dongguan CNC machining, good cooling and lubrication conditions can reduce the grinding temperature, reduce friction between the grinding wheel and the workpiece, thereby improving the machining surface quality and extending the service life of the grinding wheel. A suitable cooling fluid can also promptly flush away the grinding chips generated during the grinding process, avoiding secondary scratches on the workpiece surface caused by grinding chips. At the same time, cooling and lubrication can also reduce the dimensional error of the workpiece caused by thermal deformation, ensuring machining precision.

For precision components integrated with electronic modules—such as medical sensors or precision instrument cores—the high flatness and low roughness surface achieved through optimized grinding parameters lay a solid foundation for subsequent assembly with automatic placement machines. These machines enable high-precision, automated placement of microelectronic components (e.g., chips, resistors) on the ground workpiece surfaces, ensuring consistent positioning accuracy and reducing human-induced errors, which is essential for meeting the multi-functional and high-reliability requirements of modern precision products.

The optimization of process parameters for precision grinding is a complex and delicate process that requires comprehensive consideration of multiple factors such as grinding wheel speed, feed rate, grinding depth, and cooling and lubrication. Only through continuous testing and research to find the most suitable parameter combination can the goals of high efficiency, high precision, and high quality be achieved in precision part machining, meeting the strict requirements for precision grinding in various fields.