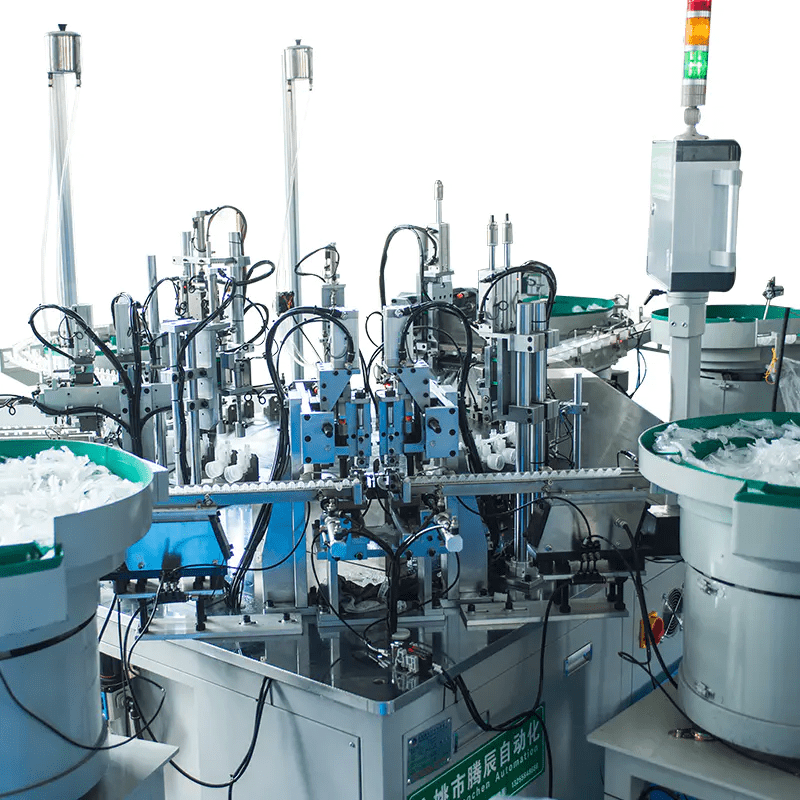

Precision Vacuum Bottle Assembly Machine

Vacuum bottles are widely used in cosmetics, pharmaceuticals, and daily necessities due to their excellent sealing and preservation performance. However, the assembly of vacuum bottles has extremely high requirements for precision—even a tiny deviation may lead to air leakage, affecting product quality and shelf life. Traditional assembly methods rely on manual operation or semi-automatic equipment, which are plagued by low efficiency, high defect rates, and difficulty in adapting to multi-specification production. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has launched a precision vacuum bottle assembly machine that integrates high precision, flexibility, and efficiency, helping enterprises break through production bottlenecks.

The Core Pain Points of Vacuum Bottle Production: The Urgency of Precision Upgrade

The core of vacuum bottle quality lies in sealing performance. Data shows that the leakage rate of products assembled manually can reach more than 5%, and the vacuum insulation performance will decrease by about 35% once leakage occurs. In addition, the market demand for vacuum bottles is increasingly diversified, with different specifications such as capacity, caliber, and material. Traditional standardized equipment can only meet fixed production needs, and switching between specifications takes a long time. At the same time, the low precision of conventional equipment (general domestic precision is ±0.05mm) leads to poor assembly consistency, which restricts the development of enterprises towards high-end markets.

Ruizhi Precision Assembly Machine: Core Advantages of Non-Standard Customization

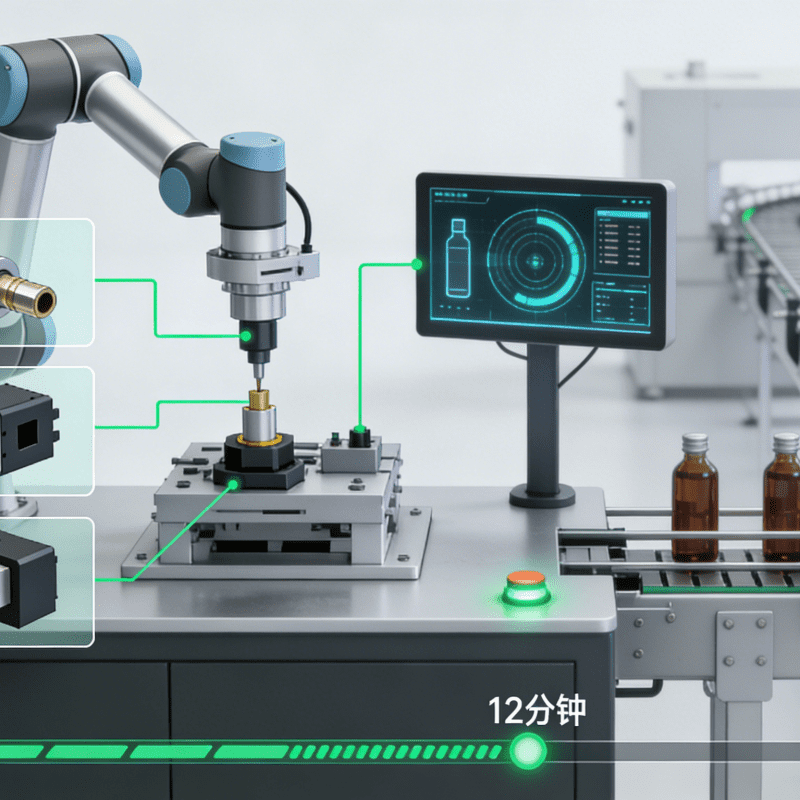

Targeting the pain points of the industry, Ruizhi’s precision vacuum bottle assembly machine has achieved a qualitative leap in technology. Firstly, it adopts high-precision servo control and flexible tooling design, with an assembly precision of ±0.001mm, which is far higher than the industry average. The integrated helium mass spectrometer leak detector can achieve a minimum detectable leak rate of 1×10^-12 Pa·m³/s, ensuring the leakage rate of finished products is less than 0.3%. Secondly, relying on professional non-standard customization capabilities, it can be tailored to different product parameters. The production line can be switched between different specifications in 15 minutes, easily meeting the diversified production needs of enterprises. Finally, the fully automatic assembly process reduces manual intervention, increasing production efficiency by 35% compared with traditional methods, and the finished product rate reaches 99.5%.

Practical Value Verification: Helping Enterprises Achieve High-Quality Development

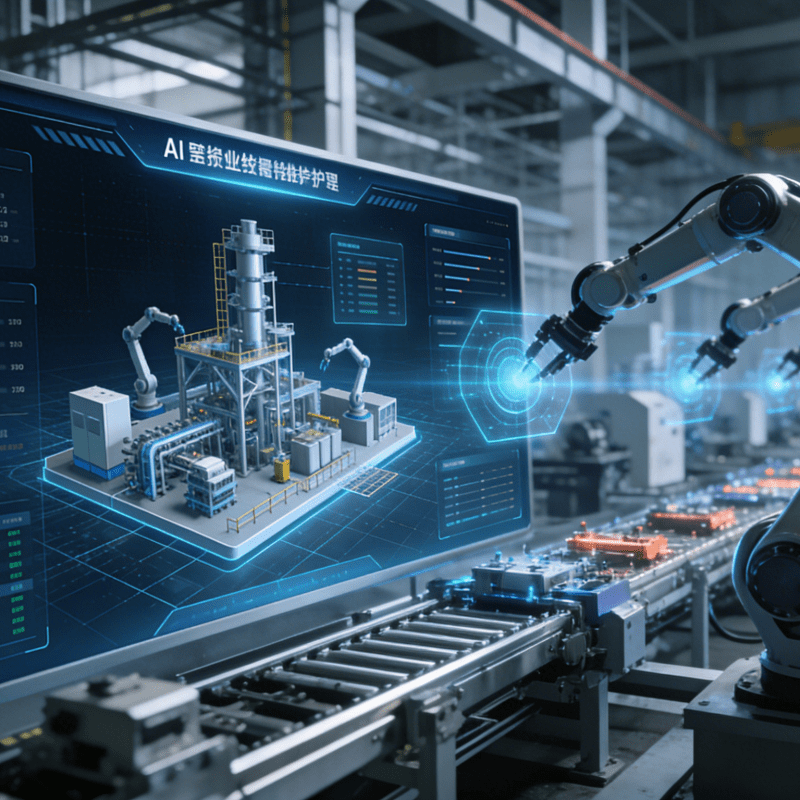

The value of Ruizhi’s precision vacuum bottle assembly machine has been fully verified in practical applications. A well-known cosmetic enterprise once faced the problem of unstable product quality due to low assembly precision. After adopting Ruizhi’s customized precision assembly line, the product leakage rate dropped from 4.2% to 0.2%, and the production efficiency increased by 40%, saving 60% of labor costs. In addition, the machine can be integrated with the enterprise’s intelligent management system to realize real-time monitoring of production data, laying a foundation for lean production. Ruizhi also provides one-stop services from scheme design to after-sales maintenance, solving the worries of enterprises in the process of equipment use.

In the context of increasingly fierce market competition, precision and efficiency have become the core competitiveness of vacuum bottle manufacturers. Ruizhi Intelligent Manufacturing relies on advanced non-standard automation technology to inject strong momentum into the high-quality development of enterprises. Choosing Ruizhi’s precision vacuum bottle assembly machine is the key to seizing market opportunities and achieving sustainable development.

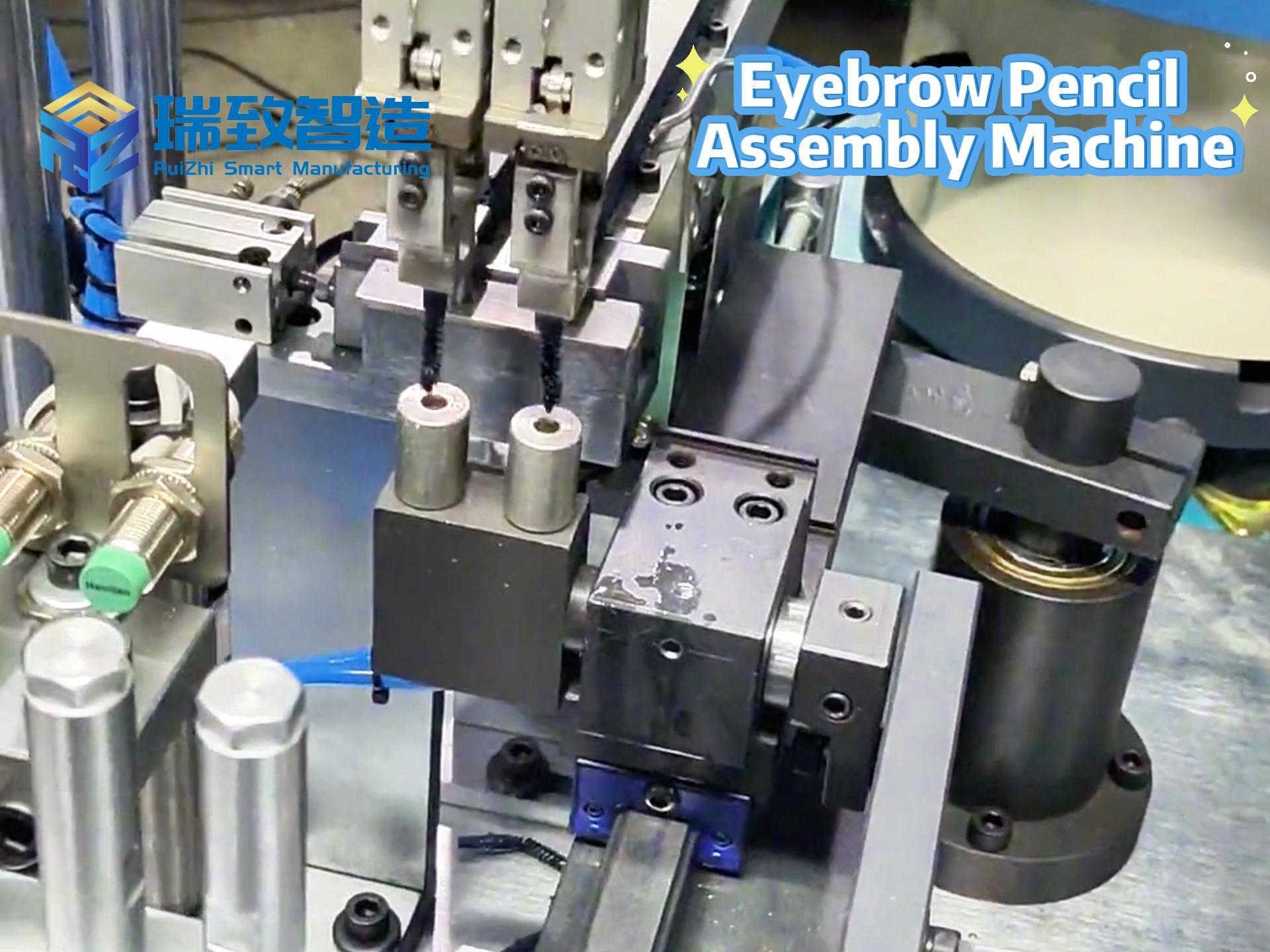

Mechanical parts assembly supplier

Industrial component assembly