Amid the global wave of manufacturing transformation towards intelligence and high-endization, precision machining plays a pivotal role as the “industrial heart”. This manufacturing technology, which aims for micron-level or even nanometer-level precision, transforms design drawings into high-precision components through core means such as numerical control (NC) machining, precision inspection, and special processes. It underpins technological breakthroughs in cutting-edge fields like aerospace, medical devices, and semiconductors. Its core value lies not only in the ultimate control of dimensional errors but also in achieving a leap in the performance of functional components through the in-depth coupling of material properties and processing technologies. This article will analyze how precision machining becomes the core driving force for the upgrading of modern industry from the dimensions of technical systems, material adaptation, and industry trends.

Core Technical System: The Three-Level Progressive Logic of Precision Control

The technical framework of precision machining can be summarized as a trinity model of “equipment precision – process optimization – inspection closed-loop”:

- Precision Foundation of NC Equipment

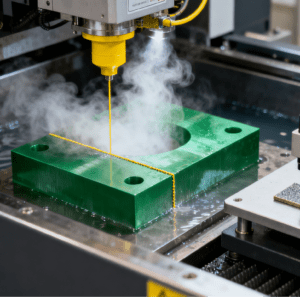

Five-axis machining centers achieve multi-dimensional cutting through a double-swing head structure, with a positioning accuracy of up to ±5μm. Combined with the high-speed operation of the electric spindle (rotational speed ≥40,000rpm), they can complete the machining of complex curved surfaces of aerospace blades.Slow wire electrical discharge machining (EDM) machines use electrode wires with a diameter of 0.02mm to realize micro-machining of cemented carbide molds, controlling the surface roughness to Ra ≤ 0.1μm.

- Intelligent Optimization of Process Parameters

Based on the material removal rate model, cutting speed, feed rate, and tool angle are dynamically adjusted through machine learning algorithms. For example, when machining titanium alloys, reducing cutting heat (controlling temperature rise ≤ 80℃) to minimize material deformation, combined with vibration cutting technology (frequency 20kHz), can increase tool life by more than 30%. This transformation from “empirical processes” to “data-driven processes” is becoming the core path for precision breakthroughs.

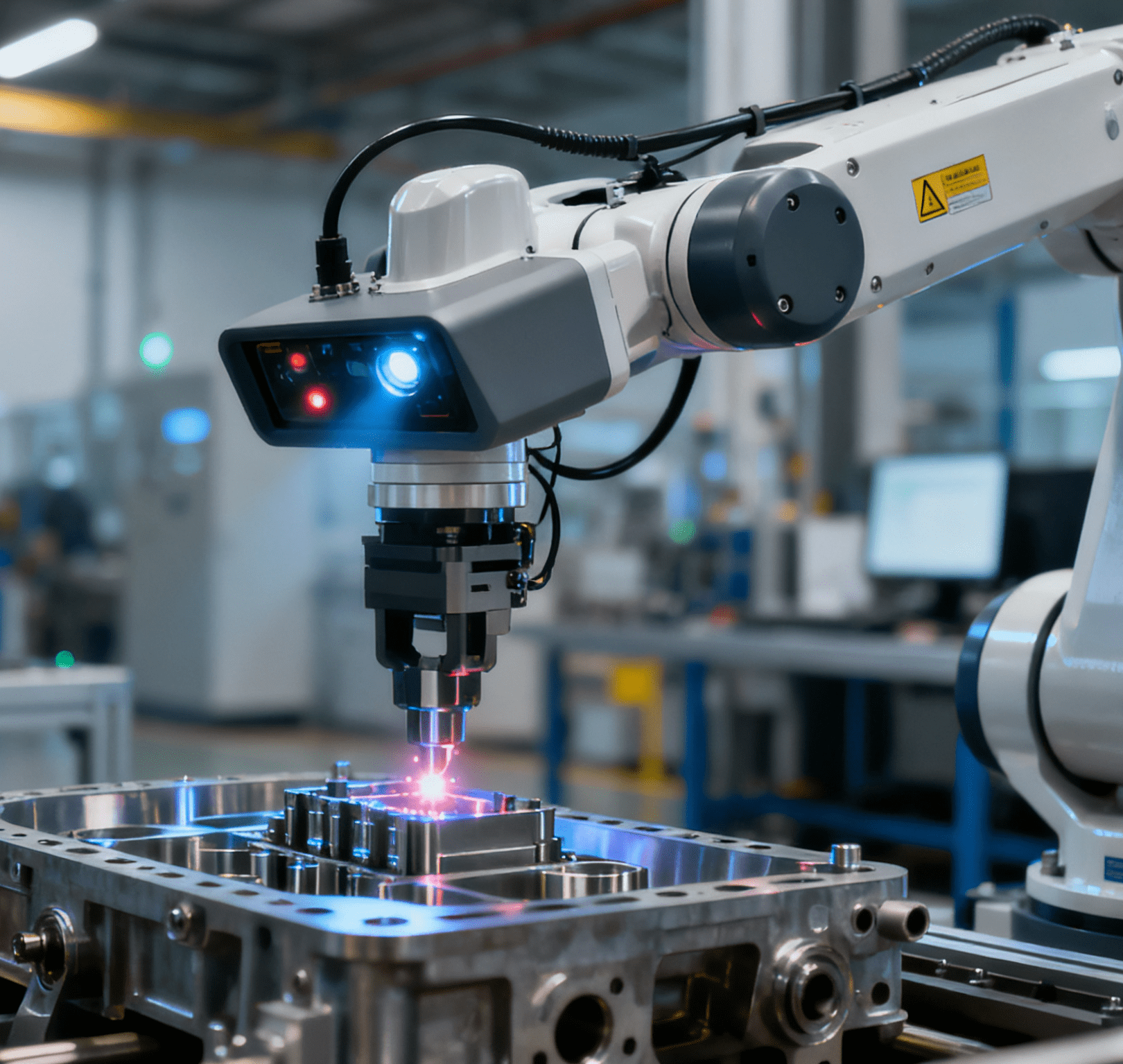

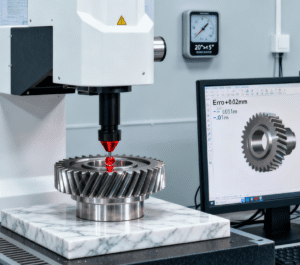

- Full-Process Inspection Closed-Loop

Coordinate Measuring Machines (CMMs) achieve 0.001mm-level dimensional inspection through ruby probes. Combined with image measuring instruments and laser scanners, they build a full-process precision traceability system from raw blanks to finished products.The application of thermal stability compensation technology further reduces the impact of ambient temperature changes on inspection results to 0.0005mm/℃.

In-Depth Interaction Between Material Properties and Processing Technologies

The physical and chemical properties of different materials determine the selection of technical routes for precision machining:

High-Strength Metal Materials (e.g., Titanium Alloys, Superalloys)

Their high hardness (≥300HB) and low thermal conductivity (thermal conductivity < 15W/m·K) lead to severe tool wear during machining. Solutions include:

Using diamond-coated tools (coating thickness 5-10μm)

Adopting high-pressure cooling systems (pressure ≥ 10MPa)

Implementing layered milling strategies (single cutting depth ≤ 0.2mm)

These measures ensure surface precision while improving machining efficiency.

Lightweight Alloy Materials (e.g., Aluminum Alloys, Magnesium Alloys)

Although they have the advantage of easy forming, their low rigidity (elastic modulus ≤ 70GPa) easily causes machining deformation. By:

Fixing workpieces with vacuum adsorption fixtures (adsorption force ≥ 50N/cm²)

Combining with high-speed cutting (cutting speed ≥ 2,000m/min) to reduce cutting force

The form and position tolerance of thin-walled parts (wall thickness ≤ 0.5mm) can be controlled within 0.05mm.

Non-Metal Materials (e.g., Ceramics, Carbon Fiber Composite Materials)

Brittle fracture and fiber delamination are the main challenges. Laser machining technology (wavelength 10.6μm) realizes stress-free cutting through thermal ablation, while ultrasonic machining (amplitude 10-50μm) crushes materials using high-frequency vibration. The combination of these two technologies enables precision machining of micro-holes with a diameter of 0.1mm.

Industrial Applications: Precision Penetration from Cutting-Edge Fields to Civilian Manufacturing

The technical value of precision machining is implemented differently across various industries:

Aerospace

The tenon precision (tolerance ±0.002mm) of aero-engine blades directly affects aerodynamic performance. A composite process of electrochemical machining and chemical milling is used to achieve burr-free machining of complex profiles.The high-strength bolt holes (precision grade H7) of landing gear components rely on gun drilling technology (depth-to-diameter ratio ≥ 30:1) to ensure hole wall integrity.

Medical Devices

The surface roughness (Ra ≤ 0.2μm) and micro-pore structure (pore diameter 50-500μm) of orthopedic implants are achieved through the combination of electrical discharge machining (EDM) and electrochemical polishing to ensure osteocyte adhesion and growth.The optical lenses of medical endoscopes (surface shape accuracy λ/10) rely on magnetorheological finishing technology to achieve nanometer-level surface precision.Notably, the thermometer visual labeling machine, a key equipment in medical device production, leverages precision machining’s visual positioning and micro-control technologies to achieve ±2μm positioning accuracy for temperature scale labels and calibration information. This ensures the clarity, consistency, and compliance of critical identification on thermometers, meeting the strict quality control requirements of the medical industry.

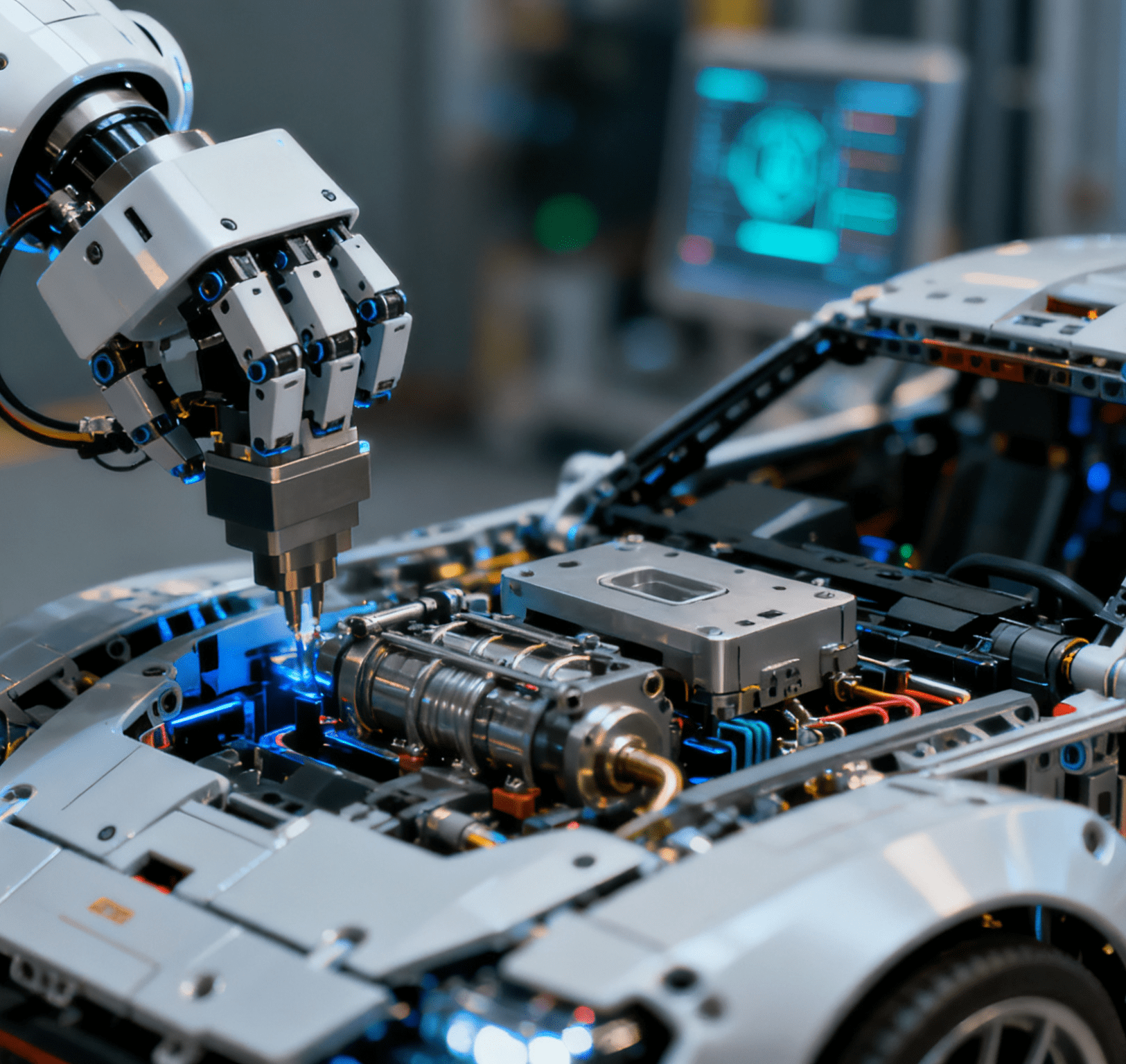

Consumer Electronics

The micro-gears (module ≤ 0.3) of smartphone camera modules are formed by powder metallurgy injection molding, combined with precision grinding (precision grade 4) to achieve silent operation.The solder ball pitch (≤ 0.4mm) of 5G chip packaging relies on vision-guided micro-spot welding technology to ensure the reliability of electrical connections.

Industry Trends: Technological Transformation Driven by Dual Engines of Intelligence and Green Development

The current precision machining industry is experiencing two core transformations:

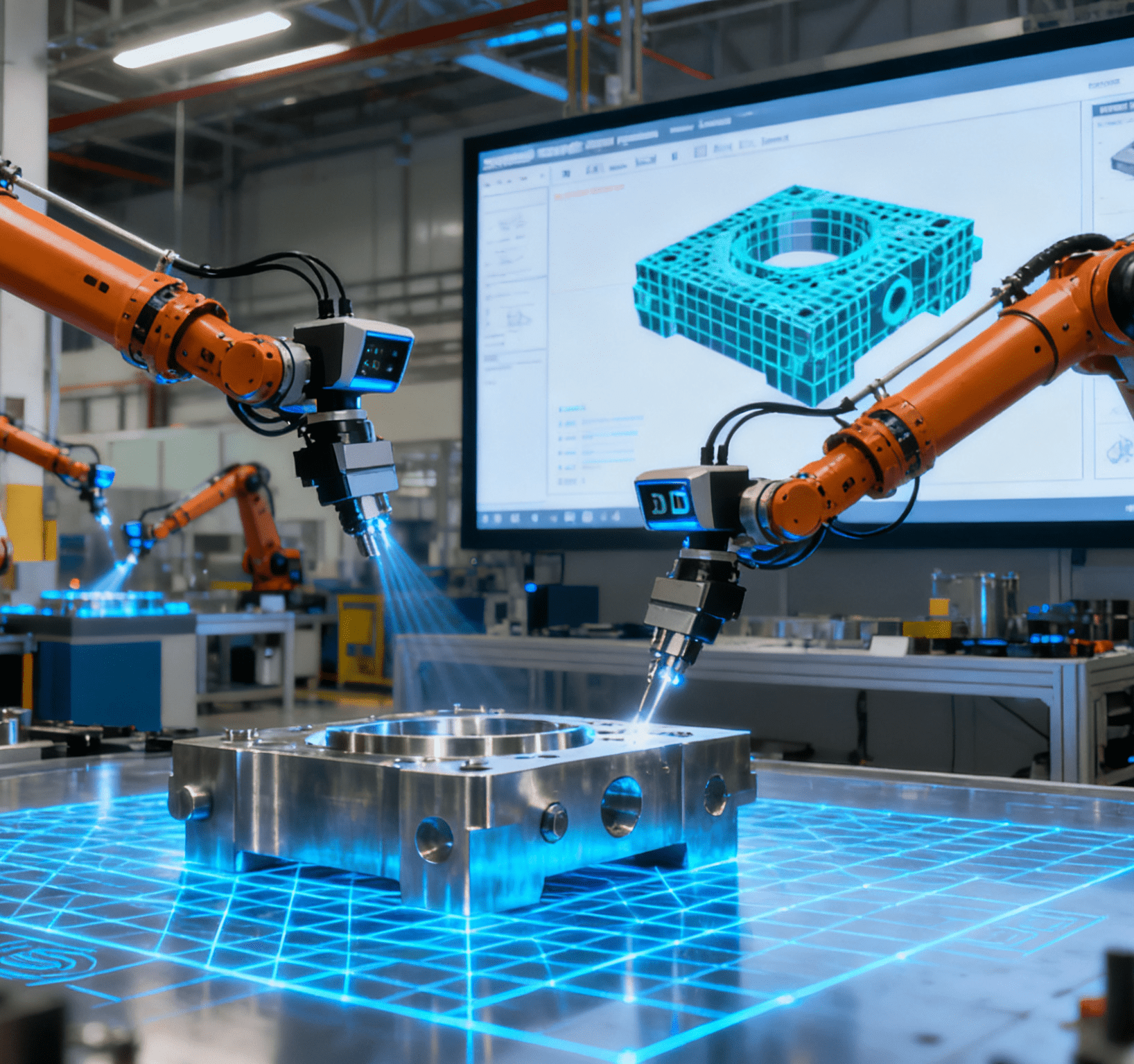

Intelligent Manufacturing Upgrade

The application of digital twin technology enables the pre-simulation of the machining process in a virtual space. By collecting more than 300 real-time parameters such as machine tool vibration, temperature, and current, a digital mirror of the machining process is built to predict tool wear in advance (prediction accuracy ≥ 90%).The collaborative operation of industrial robots and machining centers has realized the implementation of “unmanned” precision machining units. For example, the fully automatic grinding production line for bearing balls has increased the yield rate to over 99.8%.

Green Manufacturing Technology Innovation

Dry cutting technology replaces cutting fluid with air cooling (temperature -50℃), reducing waste liquid discharge by 100%. Combined with degradable tool coatings (service life increased by 20%), it meets the requirements of the EU RoHS 3.0 Directive.The integration of energy recovery systems reduces machine tool energy consumption by 15%-20%, and carbon emissions per unit output decrease simultaneously.

Precision machining is not only a manufacturing technology but also an innovation hub connecting materials science, mechanical engineering, and information technology. From micron-level dimensional control to nanometer-level surface modification, every precision breakthrough is reshaping the possibilities of high-end manufacturing. With the advancement of “Made in China 2025” and global Industry 4.0, this technology is penetrating from “high-threshold fields” such as aerospace to a wider range of manufacturing industries, becoming a core means for enterprises to enhance product added value and build technical barriers. For demand-side enterprises, understanding the technical logic of precision machining can not only optimize supply chain selection but also achieve a leap in product performance through process innovation – this is precisely the in-depth value of precision machining in the era of intelligent manufacturing.

Frequently Asked Questions (FAQs)

Q1: How are the precision levels of precision machining classified?

A1: They are usually distinguished by tolerance ranges:

Ordinary precision: 0.1-0.01mm

Precision grade: 0.01-0.001mm

Ultra-precision grade: < 0.001mm

There are significant differences in requirements across industries. For example, semiconductor wafer machining requires nanometer-level (≤10nm) precision, while general mechanical parts mostly fall into the precision grade category.

Q2: Is precision machining suitable for small-batch production?

A2: Yes. The flexibility advantage of NC machining (tool change time ≤ 30 minutes) makes it more cost-effective in prototype manufacturing and multi-variety, small-batch production. Through parametric programming and modular fixtures, it can quickly respond to personalized machining needs and avoid the high cost of traditional fixture customization.

Q3: How to select a suitable precision machining service provider?

A3: The core lies in examining three factors:

Equipment configuration: Whether it has five-axis machining centers and nanometer-level inspection equipment.

Process experience: Whether it has case experience in machining similar materials.

Quality system: Whether it has passed IATF 16949 or ISO 13485 certification.

It is recommended to prioritize suppliers with full-process capabilities of “machining – inspection – surface treatment”.