Cream jar assembly is a critical link in cosmetic production, directly affecting efficiency, defect rates, and compliance. With diversified styles and stricter quality requirements, traditional assembly methods struggle to meet factory needs. Ruizhi Intelligent Manufacturing summarizes three core optimization directions, helping cosmetic factories achieve high-quality and efficient production through non-standard automation solutions.

Improve Overall Efficiency

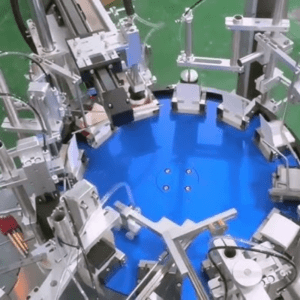

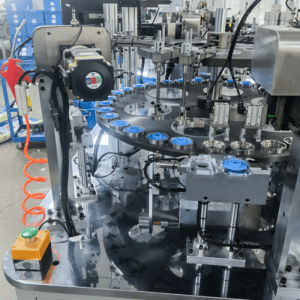

Inefficient process connection is a major bottleneck in cream jar assembly. Ruizhi adopts a dual-transport modular layout for non-standard equipment, integrating jar feeding, cleaning, filling, capping, and blanking into a seamless production line. The dual-transport design shortens material turnover time, while high-precision transfer mechanisms ensure smooth workflow. This optimization replaces 8-10 manual workers, boosts efficiency by over 60%, and eliminates human errors caused by manual handling.

Tackle Multi-Style Production

Diverse jar styles (round, polygonal, mini) often disrupt assembly stability. Ruizhi’s customized non-standard solutions solve this by equipping flexible clamping modules and servo-driven systems. Gentle clamping avoids jar damage, while servo rotation and lifting ensure uniform capping force and precise thread fitting. Quick-change fixtures enable style switching in 5 minutes, reducing downtime by over 80% and keeping defect rates below 1%, perfectly adapting to small-batch and multi-variety demands.

Achieve Sustainable Production

Optimization also requires balancing compliance and operational costs. Ruizhi’s equipment complies with cosmetic industry GMP standards, using 316L stainless steel and food-grade components to prevent contamination. Closed structures and dust removal systems maintain a clean environment. Additionally, energy-saving motors and real-time intelligent inspection systems reduce energy consumption and ensure traceability, cutting overall operational costs for factories.

Ruizhi Intelligent Manufacturing focuses on customized non-standard automation solutions. By optimizing process, adaptability, and compliance, we help cosmetic factories break through assembly bottlenecks, enhance production competitiveness in the fierce market.

How to choose a multi-component capping assembly machine suitable for your production line?