Nature: More Than a “Device”, But a “Full-Process Customized Solution”The core value of a custom assembly machine lies in breaking the traditional logic of “equipment defining production” and establishing a new paradigm of “production needs defining equipment”. It is not a partial modification of general-purpose equipment, but a full-chain customization from demand research to operation and maintenance support. Every link, ranging from 3D structural analysis of products and disassembly of assembly processes, to mechanical structure design, control system programming, on-site commissioning and later upgrades, is carried out around “specific products, specific processes, and specific scenarios”.Compared with general-purpose assembly machines, its “customized attributes” are reflected in three core dimensions:

In-depth process adaptation: It can design exclusive executive mechanisms for special processes such as riveting, ultrasonic welding, and vacuum press-fitting. For example, a “flexible pressure compensation press-fitting machine” is customized for aviation titanium alloy parts to avoid material stress damage.

Dynamic precision matching: It can achieve precise coverage from 0.001mm-level micro-assembly (such as medical catheter connectors) to 1000N-level heavy-duty assembly (such as engineering machinery bearings) according to product requirements.

Extreme scenario adaptation: It can integrate special modules such as sterile air supply, explosion-proof isolation, and high-temperature heat insulation to adapt to extreme environments like medical sterile workshops and chemical explosion-proof plants.

Application Scenarios: “Breakthrough Practices” in Four High-End Manufacturing FieldsThe value of custom assembly machines is particularly prominent in high-end manufacturing fields with high requirements for precision, processes, and scenarios. Each case represents a “pain point-oriented” customized innovation.

Medical Devices: Dual Breakthroughs in Sterility and PrecisionThe assembly of medical devices is comparable to “a dance on the tip of a needle”. Taking the assembly of catheters and needles for disposable infusion sets as an example, it not only requires 0.01mm-level coaxiality to ensure smooth infusion, but also demands full-process sterility to avoid contamination. A medical device enterprise once tried to produce with general-purpose assembly machines, but the defect rate reached as high as 15% due to the “inability to achieve both sterility and precision simultaneously”. However, the custom assembly machine provided an exclusive solution: by integrating a “sterile negative pressure workbench + machine vision alignment system + servo precision screwing mechanism”, it realized the full-process automation of automatic needle feeding, visual positioning calibration, and sterile screwing assembly. As a result, the defect rate dropped sharply to 0.3%, while meeting the requirements of GMP (Good Manufacturing Practice for Drugs).

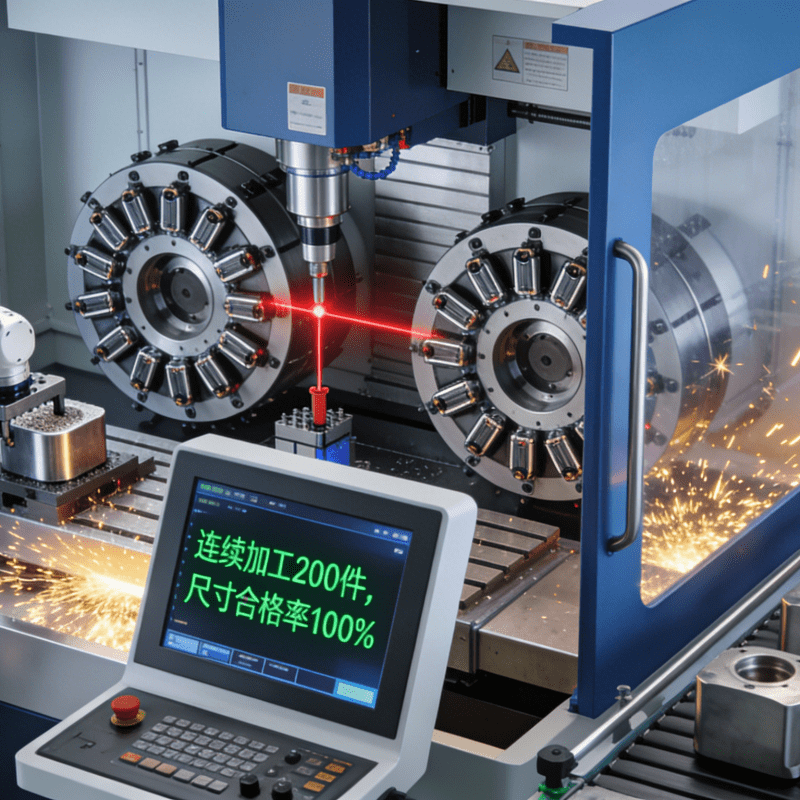

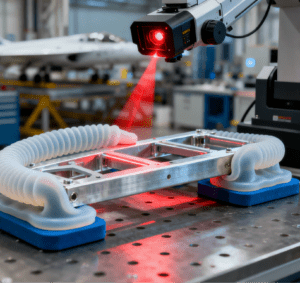

Aerospace: “Customized Solutions” for Assembly of Special MaterialsSpecial parts in the aerospace field often leave general-purpose equipment “helpless” due to their special materials and complex structures. For instance, in the assembly of aluminum alloy brackets for satellite antennas, it is necessary to ensure that the fitting error between the bracket and the base is ≤ 0.003mm, while avoiding deformation of the aluminum alloy material caused by rigid clamping. The innovation of the custom assembly machine lies in: adopting “flexible silica gel fixtures” instead of traditional rigid fixtures, with real-time feedback of clamping force through pressure sensors; cooperating with a laser tracking measurement system to dynamically correct position deviations during the assembly process; finally achieving “zero-deformation assembly”, and the qualification rate increased from 78% (with general-purpose equipment) to 99.5%.

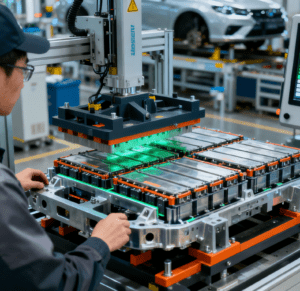

New Energy Vehicles: Flexible Adaptation to Multi-Model RequirementsThe “fast model iteration and high demand for customization” in the new energy vehicle market have exposed the “rigid shortcomings” of general-purpose assembly machines. A car manufacturer once needed to equip 3 sets of general-purpose equipment to adapt to the assembly of 3 different specifications of battery packs, which not only incurred high costs but also took up to 4 hours for model changeover. The custom assembly machine solved this dilemma through “modular design + parameterized programming”: the core mechanism of the equipment adopts quick-dismantling modules, enabling rapid replacement of cell positioning fixtures; the control system presets assembly parameters for 3 vehicle models. During model changeover, only the corresponding program needs to be called, and automatic calibration is performed with visual recognition. As a result, the model changeover time is reduced to 20 minutes, a single set of equipment can meet the production needs of multiple vehicle models, and the equipment investment cost is reduced by 60%.

Consumer Electronics: Precision Assembly for Large-Size Fragile TV PanelsTV panels, as core components of consumer electronics, pose unique assembly challenges: large sizes (ranging from 32 inches to 85 inches), fragile glass substrates (prone to cracking under uneven pressure), and dense screw distribution (up to 50+ screws per panel requiring uniform torque). General-purpose screw-fixing machines struggle with “one-size-fits-all” limitations—they cannot quickly adapt to different panel dimensions, and rigid clamping easily damages the glass. To address this, custom assembly machines integrate a 4 – Axis Robotic TV Panel Screw – Fixing System tailored to TV manufacturing needs. The 4-axis robot (combining X/Y/Z linear motion and Z-axis rotational adjustment) flexibly covers large panel surfaces, eliminating dead zones that fixed mechanical arms cannot reach; paired with a high-precision vision system, it automatically identifies screw hole positions with ±0.02mm accuracy, even if the panel has minor placement deviations. Additionally, the system’s torque control module is customized to apply 0.5–2 N·m of adjustable torque (matched to panel materials like LCD or OLED), preventing glass cracking from over-tightening or panel loosening from under-tightening. For a TV manufacturer producing 6 panel models, this custom system cuts model changeover time from 2 hours (general-purpose machines) to 15 minutes (via parameterized programming) and raises the screw-fixing qualification rate from 92% to 99.8%, fully meeting the high-efficiency and high-precision demands of mass TV production.

Core Support: The “Technology Triangle” Behind CustomizationThe ability of custom assembly machines to achieve “tailor-made solutions” is inseparable from the collaborative support of three core technologies: mechanical design, intelligent control, and digital simulation. These three constitute the “technology triangle” of customization capabilities.

Modular Mechanical Design: Balancing Exclusivity and FlexibilityCustomization is not a “one-time design”, but achieves “exclusivity + reusability” through modular disassembly. The design team disassembles the equipment into standard units such as grasping modules, positioning modules, assembly modules, and detection modules. In response to the special needs of different products, only the core executive units (such as fixtures and pressure heads) are designed exclusively, while the other modules reuse mature solutions. This model not only ensures accurate adaptation to non-standard needs but also shortens the design cycle—from the traditional 3-6 months to 1-2 months, while reducing later maintenance costs.

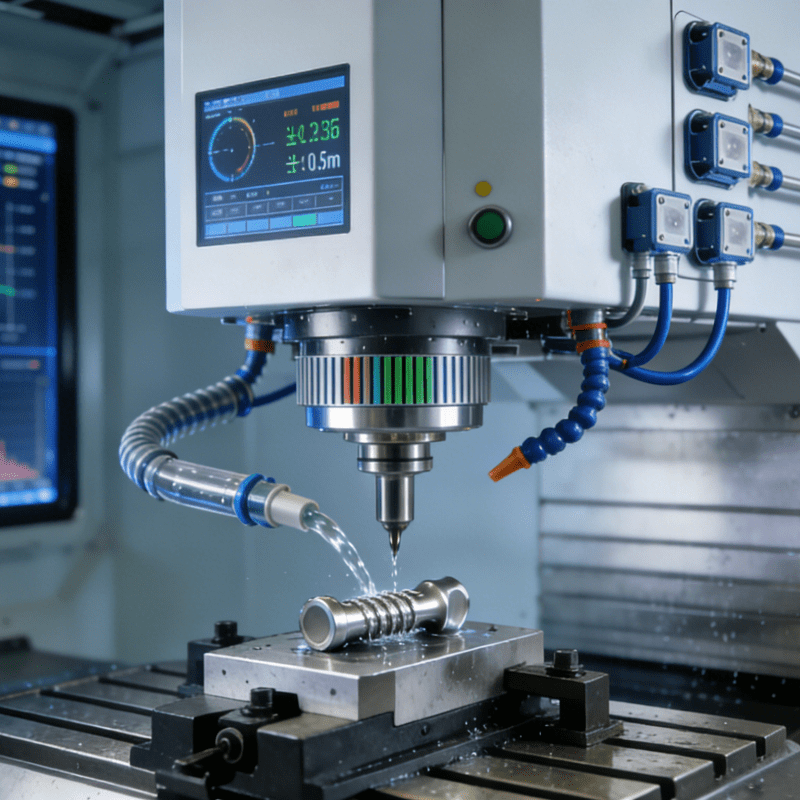

Intelligent Control and Perception Integration: Achieving “Precision + Controllability”The “precision” of custom assembly machines stems from the in-depth integration of control and perception systems. On the one hand, a dual-control solution of PLC (Programmable Logic Controller) + motion controller is adopted to precisely control key parameters such as the motion trajectory of the robotic arm and assembly pressure. For example, in the welding of electronic components, the welding time can be controlled within ±0.01 seconds. On the other hand, perception devices such as machine vision, force sensors, and laser measurement are integrated to detect data such as assembly position, pressure, and gap in real time. Once a deviation occurs, adjustments or alarms are triggered immediately, realizing closed-loop control of “assembly – detection – feedback”.

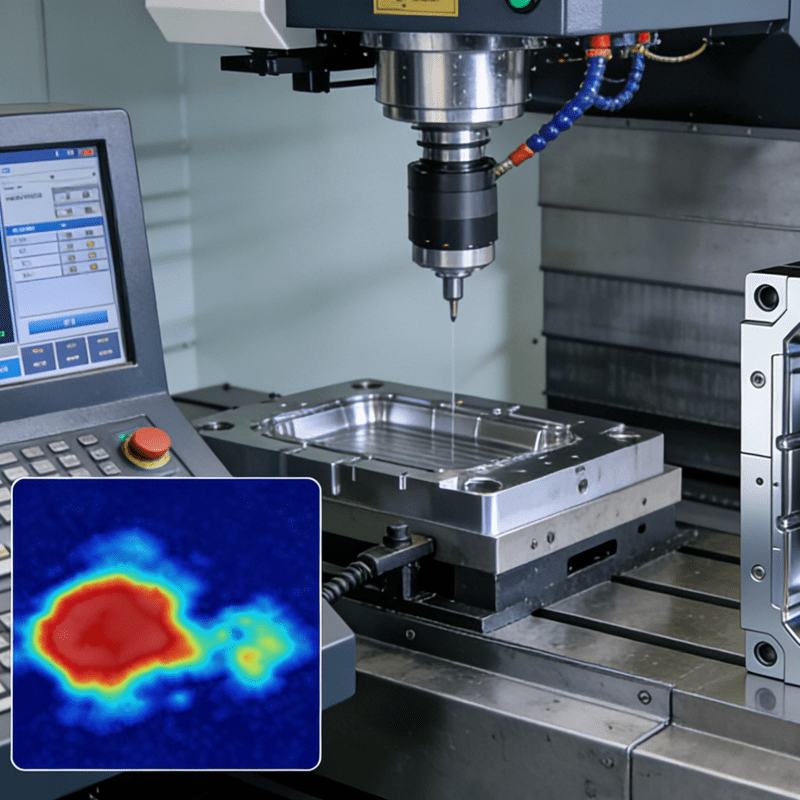

Digital Simulation Preview: Avoiding “Trial-and-Error Costs”The greatest risk of customization is “inconsistency between actual operation and design”, and digital simulation technology avoids this problem in advance. Before equipment manufacturing, the design team builds a virtual assembly scenario based on the 3D model of the product. Through simulation software, it simulates the equipment’s motion trajectory, assembly force, and production rhythm, and predicts potential problems such as interference and insufficient precision. In a customization project of an aerospace component enterprise, the simulation revealed the interference risk between the fixture and the part, and the design plan was optimized in advance, avoiding a loss of 500,000 yuan caused by later equipment modification, while reducing the on-site commissioning time by 40%.

Industry Value: From “Cost Reduction and Efficiency Improvement” to “Competitive Reconstruction”For manufacturing enterprises, the value of custom assembly machines has long gone beyond “improving efficiency” and has become a key driver for reconstructing core competitiveness.In terms of cost control, it reduces the repeated investment in general-purpose equipment through “one equipment adapting to multiple scenarios”, and at the same time reduces the defect rate by more than 50%, significantly reducing rework and material waste. In terms of technical barriers, exclusive customized solutions can be deeply bound to the enterprise’s core processes, forming an exclusive “equipment – process” competitiveness. For example, the custom assembly machine of a medical device enterprise, due to its adaptation to the special structure of its patented products, has become a “technical moat” that competitors find difficult to replicate. In terms of transformation support, it enables enterprises to undertake high-value-added non-standard orders. After introducing a custom assembly machine, a precision electronics enterprise successfully undertook the assembly order of micro-sensors in the military industry, and its gross profit margin increased from 25% to 55%.

Future Trends: In-depth Integration of Customization with “Flexibility and Intelligence”As the manufacturing industry upgrades to “Industry 4.0”, custom assembly machines are evolving towards “greater flexibility, higher intelligence, and stronger connectivity”, and will present three major trends in the future:

Flexible Customization: From “Single-Product Adaptation” to “Multi-Product Self-Adaptation”The new generation of custom assembly machines will integrate AI visual recognition and adaptive fixture technology, enabling automatic recognition of products of different specifications and adjustment of assembly parameters without replacing modules. For example, a custom cap assembly machine of a daily chemical enterprise can automatically recognize three types of caps (circular, square, and special-shaped), adjust the grasping angle and screwing torque in real time, and realize seamless switching of “mixed-line production”.

Digital Twin Empowerment: Full-Lifecycle Customized ServicesWith the help of digital twin technology, custom assembly machines will realize the full-process digitalization of “virtual design – virtual commissioning – remote operation and maintenance”. Enterprises can preview the equipment operation effect and debug parameters through virtual models. After the equipment is delivered, it is connected to the cloud platform through the industrial Internet. Manufacturers can remotely monitor the equipment operation data, provide early fault warnings, and even offer “on-demand upgrade” customized function iteration services.

Green Customization: Energy-Saving Design Adapting to “Dual Carbon” RequirementsDriven by the “dual carbon” (carbon peaking and carbon neutrality) goals, custom assembly machines will incorporate energy-saving technologies—adopting servo energy-saving motors to reduce energy consumption by more than 30%, and integrating waste heat recovery modules to utilize the heat generated during equipment operation. At the same time, the machine body will use recyclable aluminum alloy materials to reduce carbon emissions during the manufacturing process, realizing the coordination of “customization and greenization”.

Conclusion: Customization, the “Inevitable Path” for the High-End Development of ManufacturingThe shift from the “one-size-fits-all” approach of general-purpose equipment to the “tailor-made” nature of custom assembly machines reflects the concept upgrade of the manufacturing industry from “scale first” to “value first”. The core competitiveness of custom assembly machines lies not only in their accurate adaptation to non-standard needs but also in their ability to serve as an “extended carrier” for enterprises’ core processes, promoting the transformation of manufacturing enterprises from “processing-oriented” to “innovation-oriented”.