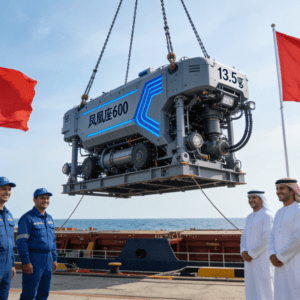

Recently, exciting news emerged from the global high-end plastic molding equipment sector: the 4000T ultra-large two-platen injection molding machine independently developed by Bole has completed production, testing, and long-distance transportation, and was successfully delivered and commissioned at a top manufacturer in Mexico. This delivery not only marks another recognition of China’s technological strength in the field of ultra-large, high-precision molding equipment by the international high-end market, but also represents a significant milestone for Bole in the American market.

Cutting-Edge Equipment Empowers Customers to Scale New Heights in Manufacturing

The successfully delivered Bole flagship model DK4000T ultra-large two-platen injection molding machine is specially designed for the integrated molding of large-size, high-complexity plastic parts in the automotive, logistics, large household appliance, and industrial sectors. Boasting ultra-strong clamping force, the equipment is characterized by high precision, high stability, and high energy efficiency. Integrated with advanced control systems, independently developed process software, and hydraulic designs, it ensures excellent repeat accuracy while significantly reducing energy consumption. This provides strong support for customers to achieve cost reduction, efficiency improvement, and strict quality control in large-scale production, helping them enhance their competitiveness in the North American and global supply chains.

Core Technological Strength Lays the Foundation for Excellent Production

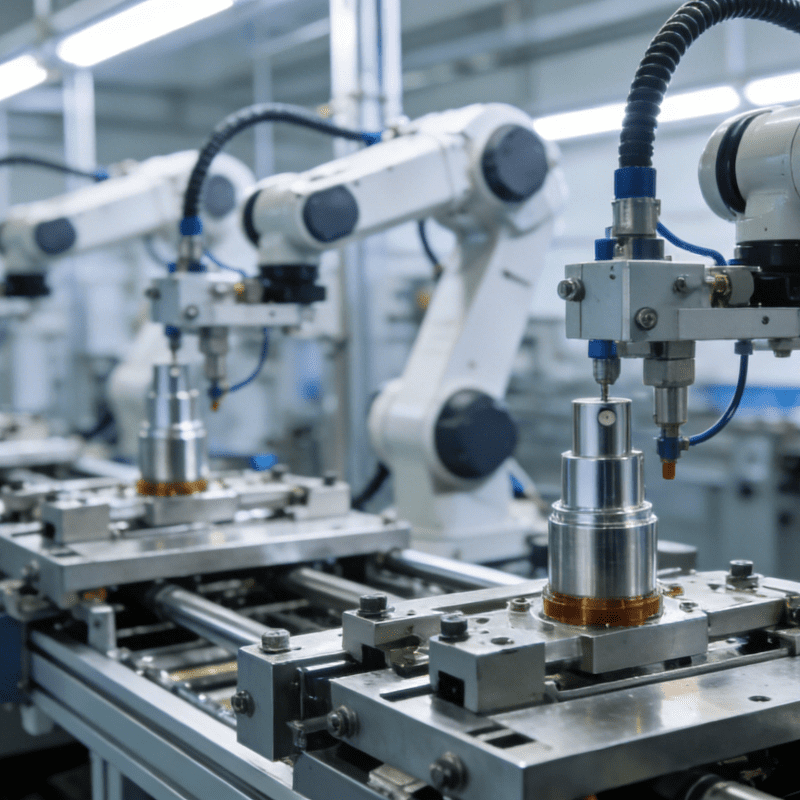

Ultra-Strong Structure and Precision Stability

The independently developed two-platen structure and high-rigidity integral frame design ensure that the clamping and injection systems maintain extreme stability during long-term, high-load continuous production, providing a fundamental guarantee for the dimensional accuracy and consistency of ultra-large products.

Outstanding Energy-Saving Performance

Equipped with a high-performance servo drive system and paired with Bole’s independently developed software system, the machine achieves on-demand energy supply. Compared with traditional equipment, it significantly reduces energy consumption per unit product, aligning with the global trend of green and sustainable development in manufacturing and helping customers lower long-term operational costs.

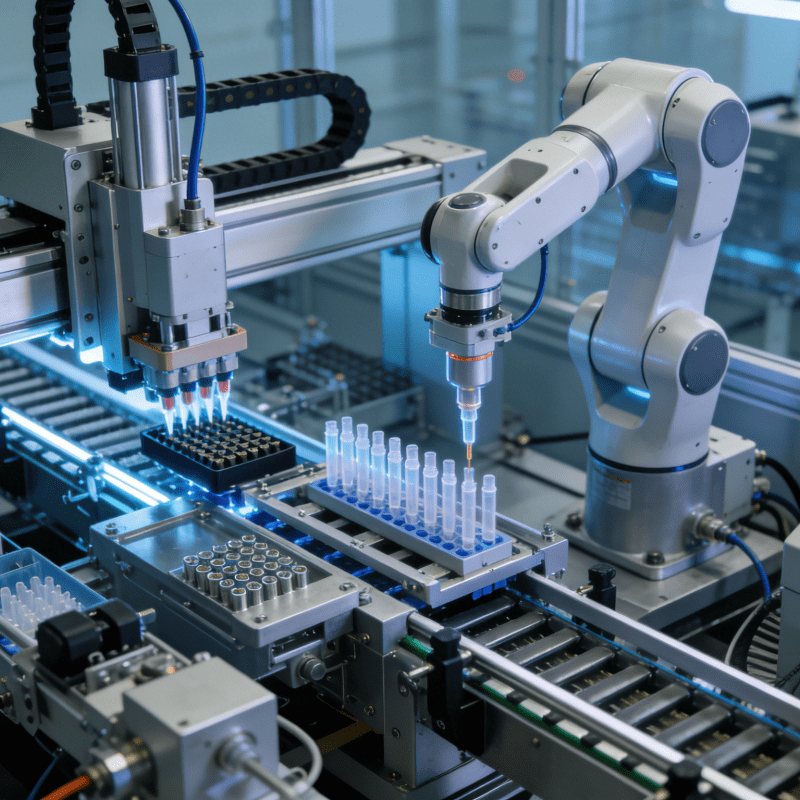

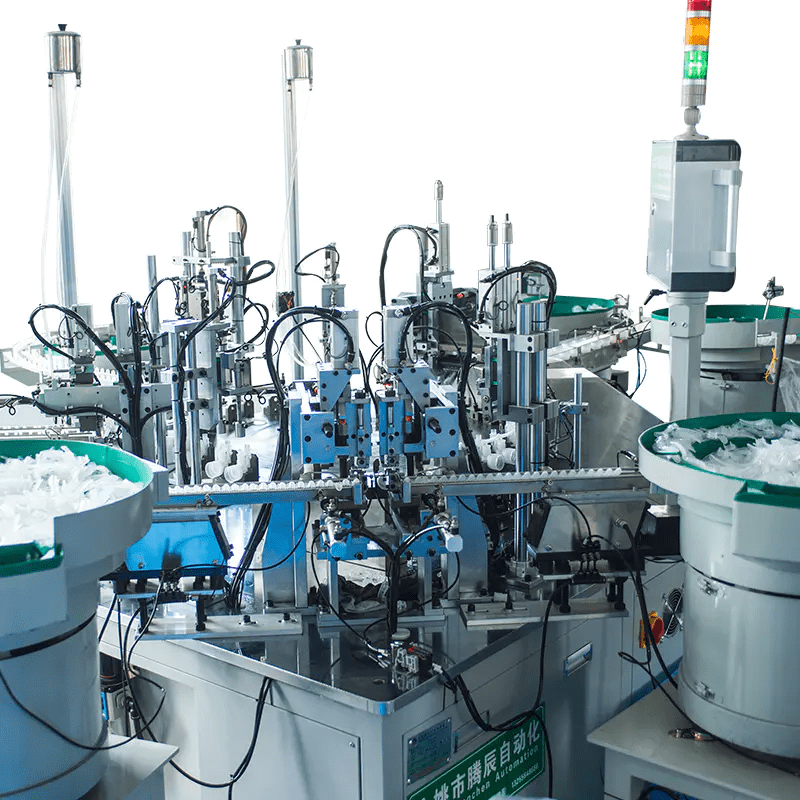

Intelligent Production Control

Featuring an advanced intelligent control system, it offers functions such as process parameter optimization, real-time status monitoring, predictive maintenance alerts, and production data management. Notably, the equipment is equipped with a Joustava tärysyöttölaite, which realizes precise and stable automatic conveying of raw materials and small accessories, seamlessly connecting with the injection molding process. This not only improves the continuity and automation level of production but also reduces manual intervention and material waste, providing critical equipment support for customers to move towards “Industry 4.0” smart factories.

High Production Flexibility

The pull rod and compatible automatic quick mold change system can greatly shorten the mold change time for large molds, improve the comprehensive utilization rate of the equipment, and quickly respond to the market challenges of multi-variety, batch production.

Regarding this procurement, the internal technical director of the customer commented: “The introduction of this ultra-large equipment is part of our strategy to enhance core manufacturing capabilities. What we value is its ability to meet the stringent requirements of our next-generation products in terms of size, strength, and efficiency. We believe it will become a reliable cornerstone of our production line.”

Industry Significance: A New Chapter in China’s High-End Manufacturing “Going Global”

The successful delivery of Bole’s DK4000T two-platen machine to Mexico holds multiple symbolic meanings:

Deepening Market Trust

This is more than just a product export; it reflects China’s high-end intelligent equipment winning deep trust from mainstream international customers through superior quality and technological added value.

Global Validation of Service Capabilities

From early-stage technical docking and customized solution design, to transoceanic transportation, local installation and commissioning, and subsequent technical support, this successful delivery fully validates Bole’s comprehensive service capabilities in providing end-to-end solutions for global customers.

This delivery demonstrates that China’s high-end equipment manufacturing industry is transforming from a “follower” to a “peer” and even a “leader” in certain fields. Leveraging its advantages in rapid response and continuous innovation, it is deeply integrating into and serving the upgrading and restructuring of the global industrial chain. As this “giant” operates smoothly in the Mexican customer’s factory, it will become a vivid microcosm for observing the new journey of Chinese manufacturing.