Table of Contents

ToggleAutomatic Iron Rod Loading/Unloading System: Redefining Heavy-Duty Material Handling Efficiency

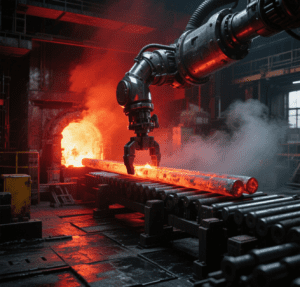

In industries where iron rods serve as the backbone of production—from steel manufacturing to machinery 加工 and construction—manual loading/unloading is a relic of the past. Handling long, heavy iron rods (ranging from 6mm to 200mm in diameter and up to 12 meters in length) is labor-intensive, dangerous, and prone to inconsistencies. Misalignments during loading can damage CNC machines, while manual lifting leads to high rates of workplace injuries. Enter the Automaattinen rautatangon lastaus-/purkujärjestelmä—a robust, intelligent solution engineered to streamline material flow, enhance safety, and boost productivity in high-volume, heavy-duty environments.

The Imperative for Automation in Iron Rod Handling

Iron rods are far from uniform: their weight (5kg to 500kg per meter), surface textures (smooth, rusted, or coated), and storage configurations (stacked, 捆扎,or on conveyors) create unique challenges:

1. Safety Risks

Manual handling of 6-meter-long rods requires 2–4 workers, exposing them to risks of back strain, cuts, and dropped loads—accounting for 30% of industrial accidents in metalworking plants.

2. Efficiency Bottlenecks

Loading a CNC lathe with a 10-meter iron rod manually takes 5–10 minutes per part, slowing down production lines and limiting machine utilization.

3. Precision Deficits

Human operators struggle to align rods within ±2mm of positional accuracy, leading to vibrations during machining and subpar surface finishes.

Core Technologies: The Brain and Brawn of Heavy-Duty Automation

1. Robust Mechanical Design for Extreme Loads

The system’s hardware is built to withstand the rigors of iron rod handling:

- Dual-Sided Gantry Cranes: Support loads up to 5 tons, equipped with anti-vibration dampeners to stabilize rods during transport.

- Magnetic/Mechanical Grippers:

- Electromagnetic Grippers: Securely hold uncoated iron rods using adjustable magnetic force (500N to 50kN), ideal for smooth surfaces.

- Hydraulic Clamps: Grip rusted or textured rods with serrated jaws, applying up to 10kN of clamping force without slippage.

- Servo-Driven Carriages: Achieve positioning accuracy of ±1mmalong X-Y-Z axes, critical for aligning rods with machine chucks or storage racks.

2. Intelligent Vision and Sensor Fusion

A combination of technologies ensures error-free handling:

- 3D Laser Scanning: Maps the position and orientation of stacked rods in real time, even in poorly lit warehouses, with 99.9% accuracy.

- Load Cells and Torque Sensors: Monitor gripper force to prevent overloading (e.g., alerting operators if a rod is bent and weighs 15% more than standard).

- RFID Integration: Reads rod specifications (diameter, length, heat treatment status) directly from tags, auto-adjusting system parameters for each part.

3. Advanced Control Software

The system’s software ecosystem enables seamless operation:

- PLC-Based Logic: Controls multi-axis movement, integrating with machine tools (CNC lathes, milling machines) via standardized protocols (EtherCAT, Modbus).

- AI-Powered Path Optimization: Algorithms calculate the shortest, safest route for each rod, reducing travel time by 20–30% compared to rule-based systems.

- HMI Interface: Provides real-time diagnostics, error logs, and production metrics (e.g., parts handled per hour, downtime reasons) for easy monitoring.

Transforming Industries: Applications Across the Value Chain

1. Steel Manufacturing: From Billets to Finished Rods

In a steel mill producing 10,000 tons of iron rods daily:

- Loading Hot Rolling Mills: The system picks red-hot billets (1,100°C) from conveyor belts using heat-resistant grippers, reducing operator exposure to high temperatures.

- Unloading Straightening Machines: Places straightened rods into storage racks with 100% alignment, enabling automated inventory management.

Result: Production throughput increases by 40%, while heat-related injuries drop by 85%.

2. Machinery Machining: Precision CNC Loading/Unloading

In a lathe workshop machining 50mm-diameter shafts:

- The system aligns rods with the machine’s chuck within ±0.5mm, eliminating manual centering (a 2-minute task per part).

- After machining, it unloads finished parts and loads new rods in a seamless cycle, boosting machine utilization from 60% to 95%.

Case Study: A tier-2 automotive supplier cuts setup time by 75%, producing 200 more parts per day with zero misloading errors.

3. Warehouse & Logistics: Efficient Palletizing and Storage

For a metal distribution center managing 10,000+ rod SKUs:

- Mixed-Length Stacking: Handles rods from 2m to 12m in the same system, using vision to optimize pallet layouts and prevent overhang.

- Automated Inventory Tracking: Updates WMS in real time as rods are moved, reducing manual inventory checks by 90%.

System vs. Traditional Methods: A Performance Breakdown

| Metric | Automatic System | Manual Handling | Semi-Automatic Cranes |

| Load Capacity | 0.5–5 tons | 0.1–0.5 tons (per worker) | 1–3 tons (fixed grippers) |

| Positioning Accuracy | ±1mm | ±10mm (variable) | ±5mm (operator-dependent) |

| Cycle Time (6m rod) | 30–45 seconds | 5–10 minutes | 2–3 minutes |

| Safety Incidents | <1 per 10,000 operations | 5–10 per 10,000 | 2–3 per 10,000 |

| Cost (USD, 10m system) | $300k–$800k | N/A (labor-intensive) | $150k–$400k (limited features) |

The Business Case: From Elastic Challenges to Tangible Gains

1. Rapid ROI Driven by Quality and Speed

- Labor Savings: Replaces 2–4 operators per line, saving $60k–$100k annually in labor costs (especially in high-wage regions).

- Yield Improvements: Reduces spring deformation and misplacement errors by 90%, critical for applications where 0.1mm misalignment causes product failure.

- Scalability: Handles 24/7 production with 98% uptime, supported by predictive maintenance (e.g., alerts for gripper wear or joint backlash).

2. Future-Ready Flexibility

- Multi-SKU Adaptability: Stores 100+ spring profiles in its database, enabling quick 切换 between compression, torsion, and extension springs with zero manual programming.

- IoT Integration: Feeds real-time data (grip force, cycle times, defect locations) to factory analytics platforms, enabling predictive quality control.

The Evolution of Spring Handling: Where Dexterity Meets Intelligence

As industries demand smaller, more complex springs (e.g., micro-coils for MEMS devices or variable-rate springs for electric vehicles), the 6-axis system evolves with:

- Self-Calibrating Tools: On-tool sensors auto-detect spring dimensions, eliminating setup time for new part numbers.

- AI-Powered Defect Prediction: Uses historical data to anticipate spring deformation risks based on material type and handling speed.

- Collaborative Safety: Equipped with 3D safety scanners, works alongside human technicians in shared workcells—ideal for R&D prototyping or low-volume custom spring production.

In a world where the performance of entire systems hinges on the precision of tiny springs, the 6-Axis Robotic Spring Pick-and-Place System is not just an upgrade—it’s a necessity. It turns the inherent challenges of elastic component handling into a competitive advantage, empowering manufacturers to achieve new levels of quality, speed, and flexibility.

#6Axis Spring Handling #Robotic Spring Assembly #Precision Pickand Place System