In the broad field of mechanical machining, precision numerical control (NC) electrochemical machining is emerging as a new approach, opening up a brand-new path for the machining of complex-shaped parts.

Breaking Through Tradition: Principles and Core Advantages of Precision NC Electrochemical Machining

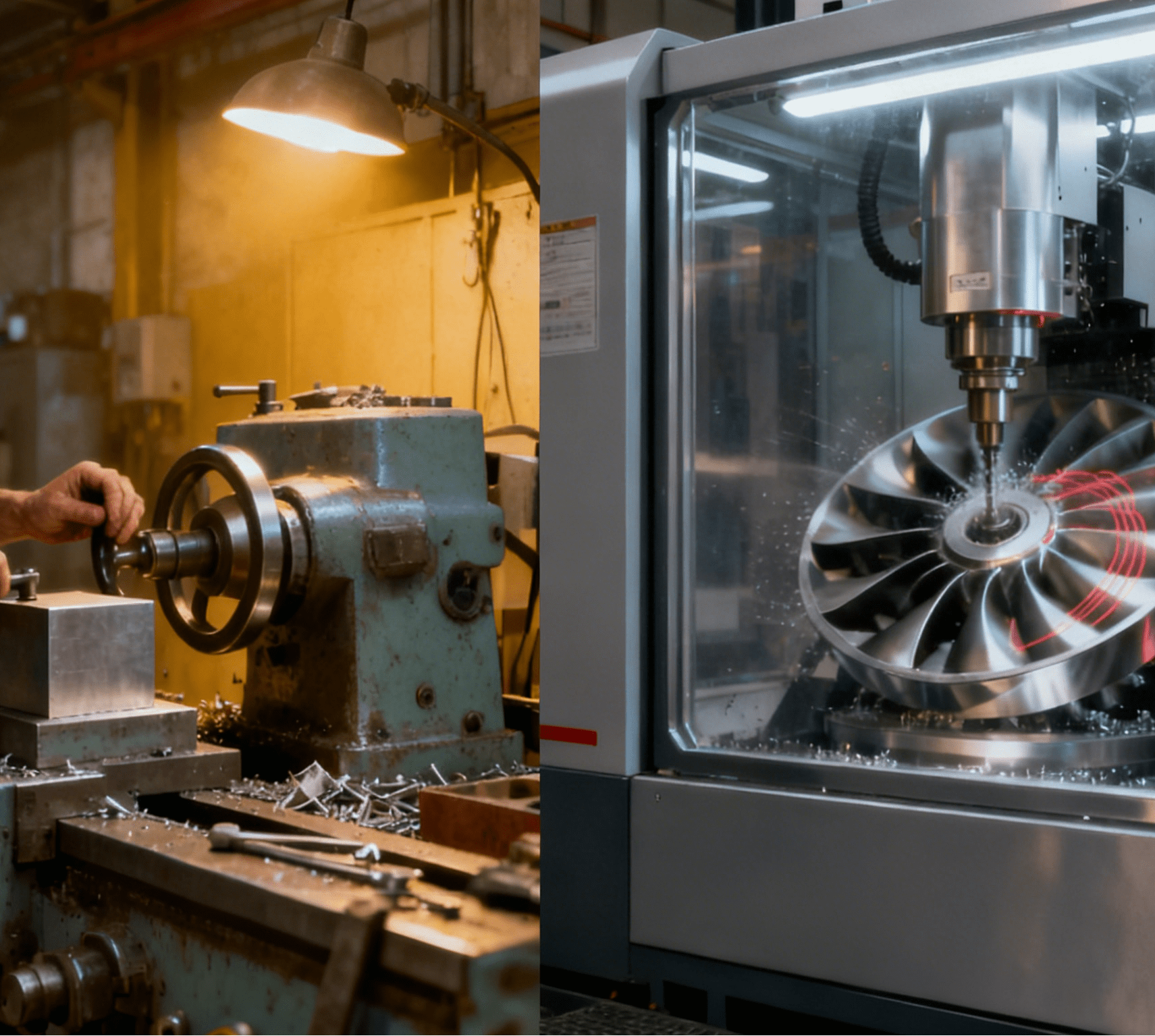

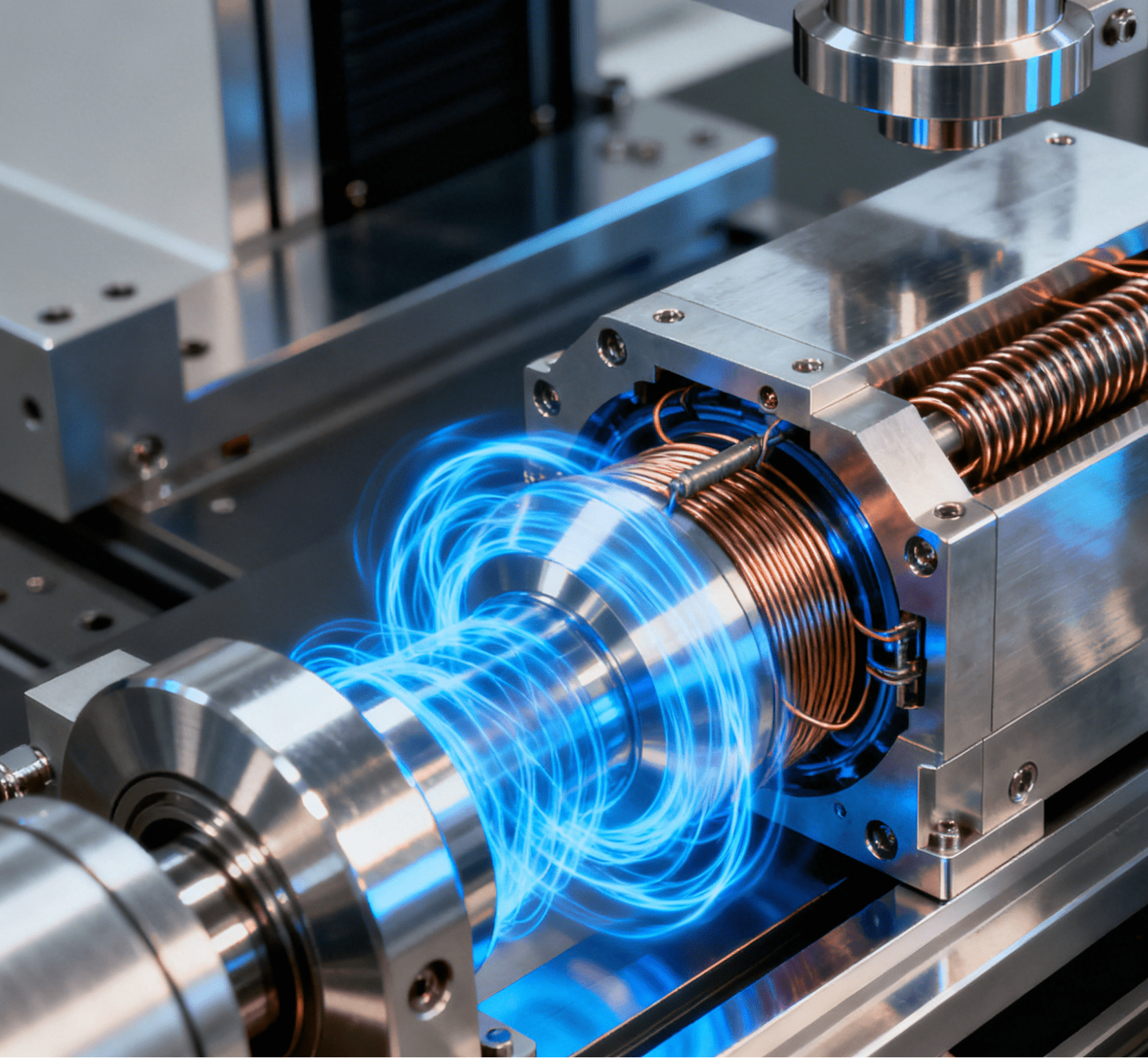

Traditional mechanical machining often faces numerous challenges when dealing with parts with complex internal structures, high-precision requirements, and special materials. For example, some aerospace components have complex shapes and difficult-to-machine materials. Conventional cutting methods not only result in low machining efficiency but also easily cause problems such as machining stress, deformation, and severe tool wear. In contrast, precision NC electrochemical machining operates based on a unique principle. It utilizes electrolysis, with the workpiece as the anode and the tool electrode as the cathode. A specific voltage is applied between them, causing ions in the electrolyte to move directionally under the action of the electric field, thereby dissolving and machining the workpiece. This non-contact machining method avoids mechanical cutting forces between the tool and the workpiece, greatly reducing the possibility of stress and deformation during machining.

Precise and Controllable: Key Technical Supports for Machining Implementation

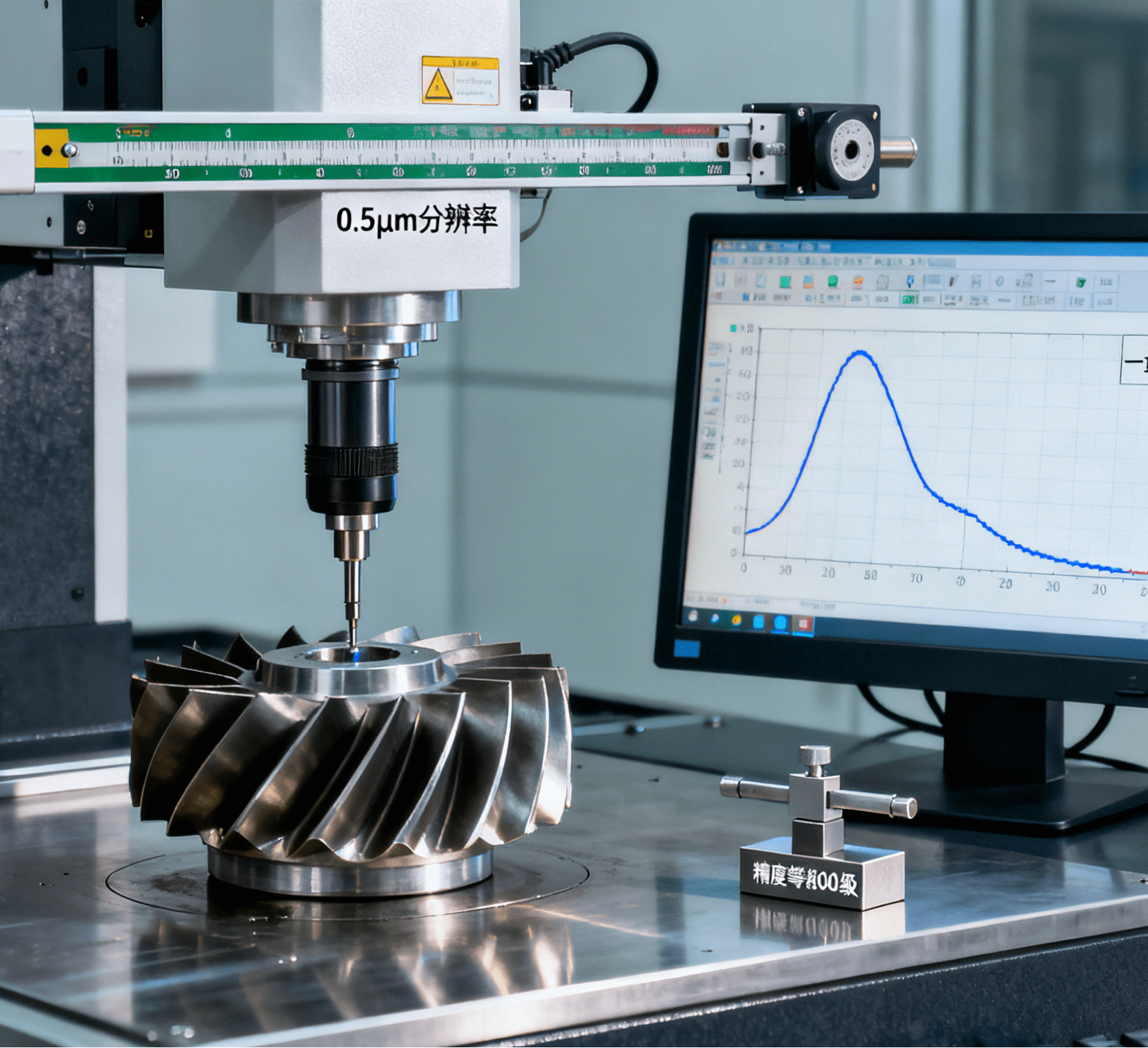

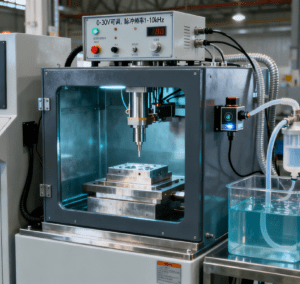

In precision NC electrochemical machining, the NC system plays a crucial commanding role. Through precise programming, it can accurately control the movement trajectory of the tool electrode relative to the workpiece, machining speed, and electrolysis parameters. This makes it possible to machine parts with complex shapes. For instance, when machining parts with complex curved surfaces and tiny internal channels, NC electrochemical machining can, according to a pre-set program, make the tool electrode perform electrolysis along a complex path, gradually shaping the desired form. Taking the turbine blades of aero-engines as an example, their internal cooling channels have complex shapes and high-precision requirements. Precision NC electrochemical machining can effectively machine these cooling channels without damaging the overall structure of the blades, ensuring the blades’ normal working performance in high-temperature and high-pressure environments.

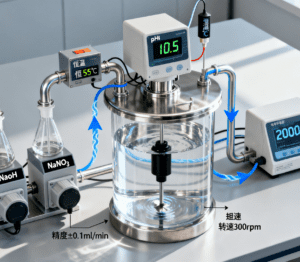

The selection and control of the electrolyte are also important links in precision NC electrochemical machining. Different workpiece materials and machining requirements require electrolytes with different compositions and concentrations. A suitable electrolyte can ensure the efficient progress of the electrolytic reaction while avoiding unnecessary corrosion or other adverse effects on the workpiece. For example, for aluminum alloy workpieces, an alkaline electrolyte with specific additives may be used to achieve a stable electrochemical machining process. Moreover, during machining, parameters such as the temperature and flow rate of the electrolyte need to be precisely controlled to ensure the consistency and stability of machining.

Another advantage of precision NC electrochemical machining lies in its ability to handle difficult-to-machine materials. For some alloy materials with high strength, high hardness, and high toughness, such as titanium alloys and nickel-based alloys, traditional cutting is extremely difficult. Electrochemical machining, however, can relatively easily machine these materials by utilizing their electrochemical dissolution characteristics in the electrolyte. This is of great significance in high-end manufacturing fields such as aerospace and medical equipment, as it can meet the manufacturing needs of complex parts made of special materials.

Furthermore, with the continuous development of technology, the machining precision and surface quality of precision NC electrochemical machining are also constantly improving. By optimizing electrochemical machining process parameters, improving tool electrode design, and adopting advanced on-line detection and feedback technologies, machining precision can be controlled within the micron or even smaller range, and good surface roughness can be achieved. For example, in the manufacturing of some precision molds, precision NC electrochemical machining can process high-quality textures and fine structures on the mold surface, improving the mold’s performance and service life. Notably, these high-precision molds further lay a solid foundation for the subsequent automated production chain— the Automatic Injection-Molded Part Feeding and Assembly system can accurately load and assemble the injection-molded parts produced by such high-precision molds, with its positioning accuracy matching the machining precision of the molds, realizing seamless connection between ultra-precision machining and automated assembly and significantly enhancing the overall production efficiency of complex components.

Potential and Shortcomings: Application Prospects and Challenges in High-End Manufacturing

However, precision NC electrochemical machining is not perfect. It requires relatively complex equipment and process control systems, and has high requirements for the technical level and professional knowledge of operators. At the same time, the treatment and recycling of electrolytes are also environmental protection issues that need attention. But with the progress of science and technology, these problems are gradually being solved.

As an emerging type of mechanical machining, precision NC electrochemical machining, with its unique machining principle and ability to handle complex shapes and difficult-to-machine materials, shows great potential in the high-end manufacturing field. It injects new vitality into the development of mechanical machining technology and is expected to play a more important role in future industrial manufacturing.