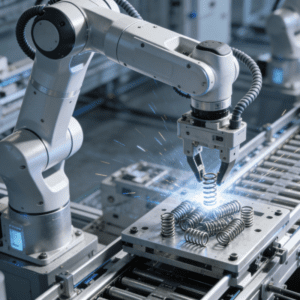

In modern assembly lines, springs are essential components in automotive, electronics, hardware, and other industries. However, their small size, elasticity, and easy deformation make manual handling inefficient and error-prone, becoming a bottleneck for production efficiency. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has launched a 6-Axis Robotic Spring Handling System, integrating high precision and fast operation to solve the pain points of spring handling, and helping enterprises optimize assembly line efficiency and product quality.

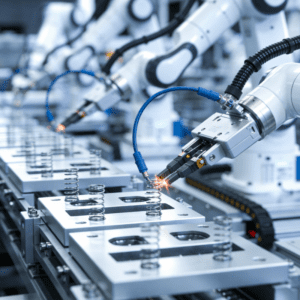

Break Through Assembly Line Efficiency Bottlenecks

Speed is the core demand of assembly line production, and Ruizhi’s 6-Axis Robotic Spring Handling System is designed to maximize handling efficiency. Equipped with high-performance servo motors and optimized motion control algorithms, the system can complete spring picking, moving, and placing in 0.3-0.5 seconds per cycle, which is 4-6 times faster than manual handling. It supports 24-hour uninterrupted operation, eliminating downtime caused by manual fatigue, and helping enterprises increase spring handling capacity by more than 50%, effectively accelerating the overall operation rhythm of the assembly line.

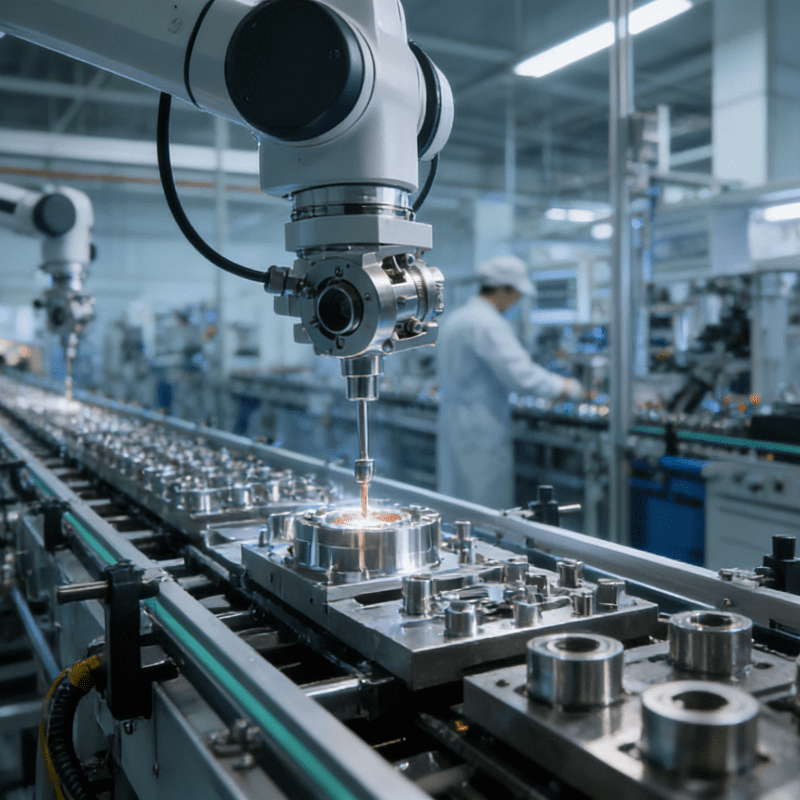

Ensure Stable Spring Assembly Quality

Precision is crucial for spring handling, as slight positioning deviations can lead to spring deformation, assembly failure, or product defects. The 6-Axis Robotic Spring Handling System of Ruizhi adopts advanced vision positioning and force control technology, with a repeat positioning accuracy of ±0.01mm. The customized soft gripper is designed according to the characteristics of springs, which can firmly grip springs of different sizes without causing deformation, ensuring the integrity of workpieces. It can accurately place springs into designated positions on the assembly line, reducing the defect rate to near zero and ensuring stable production quality.

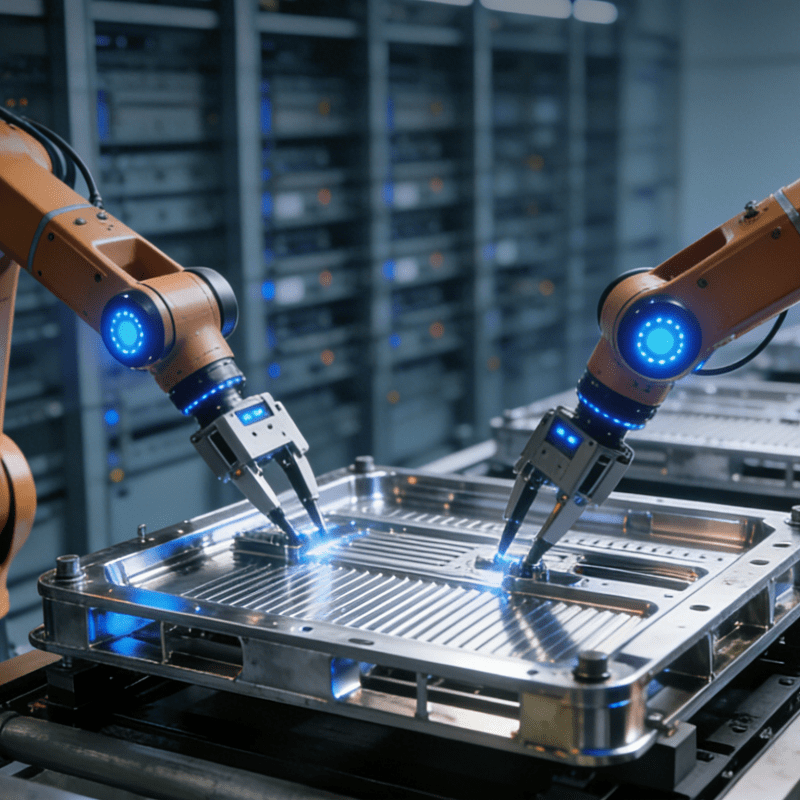

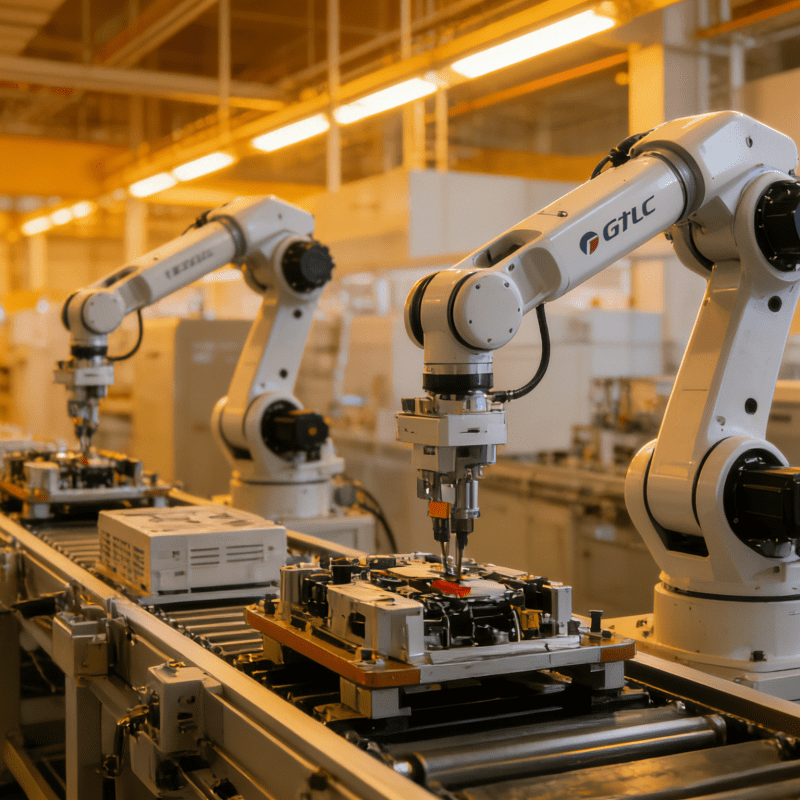

Adapt to Diverse Assembly Line Needs

As an expert in non-standard automation, Ruizhi Intelligent Manufacturing deeply understands that different assembly lines have diverse requirements for spring handling. Our 6-Axis Robotic Spring Handling System supports full customized design, including gripper type, working radius, handling speed, and control mode, according to the spring specifications, assembly process, and on-site layout of customers. The system can be seamlessly integrated with stamping machines, testing equipment, and other existing equipment, realizing automatic connection of upstream and downstream processes, and eliminating manual intervention. It also has a simple human-machine interface, which is easy to operate and maintain, reducing the professional requirements for on-site operators.

Ruizhi Intelligent Manufacturing is committed to providing reliable non-standard automation solutions for global enterprises. Our 6-Axis Robotic Spring Handling System takes precision and speed as the core, solves the pain points of spring handling in assembly lines, and helps enterprises reduce costs, improve efficiency, and enhance market competitiveness. Choose Ruizhi, and let automation empower your assembly line upgrading.