Buckles, those seemingly trivial components, are ubiquitous in modern manufacturing—securing automobile interior panels, fastening luggage zippers, fixing household appliance casings, and even connecting electronic device shells. Their small size belies their critical role: a misassembled buckle can lead to loose car interiors, leaking luggage, or unstable appliance structures. For decades, buckle assembly relied on manual work, but as manufacturing moves toward precision and high efficiency, the Automatic Buckle Feeding And Assembly System has emerged as a game-changer. It solves the pain points of manual operations and becomes a key link in upgrading the automation of industries such as automobiles, luggage, and electronics.

Why Manual Buckle Assembly Is No Longer Competitive

Manual assembly has long been the default for buckles, but its inherent limitations have become a bottleneck for enterprises pursuing high-quality production:

Efficiency bottlenecks: A skilled worker can only assemble 10–15 buckles per minute, and after 2–3 hours of continuous operation, fatigue causes speed to drop by 30% or more. For large-scale production lines (such as automobile interior assembly, which requires hundreds of buckles per vehicle), manual work can hardly keep up with the beat.

Quality instability: Buckles come in diverse shapes—U-shaped, circular, hook-type, and snap-type—and many require precise alignment with mounting holes. Manual judgment of orientation and force often leads to defects: either the buckle is not fully pressed (causing it to fall off later) or over-pressed (cracking the plastic buckle or damaging the workpiece). The defect rate is usually as high as 4–6%.

High hidden costs: Manual assembly requires frequent training to standardize operations, and the risk of finger injuries (from pressing buckles or handling small parts) adds to labor insurance and compensation costs. Moreover, reworking defective products (such as disassembling and reinstalling loose buckles) consumes additional time and materials.

Against this backdrop, the automatic buckle feeding and assembly system has become an inevitable choice for enterprises to break through production constraints.

Core Structure: How the System Achieves “Fast, Accurate, and Stable” Assembly

A mature automatic buckle feeding and assembly system integrates material organization, precise positioning, adaptive assembly, and real-time inspection into a seamless workflow. Each module is designed to address the unique characteristics of buckles (small size, diverse shapes, high alignment requirements):

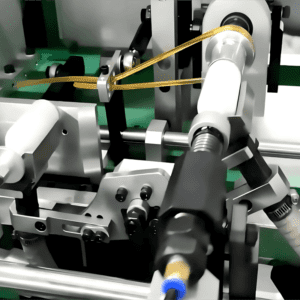

- Feeding Unit: Solving the “Disorder” of Small Buckles

The feeding unit is responsible for converting bulk, chaotic buckles into an orderly stream of materials—this is the foundation of efficient assembly. Common solutions include:

Vibration discs with customized tracks: For standard-shaped buckles (such as circular snap buckles), vibration discs use high-frequency vibration to guide buckles along spiral tracks. The track width is tailored to the buckle’s thickness, and orientation-correcting notches (e.g., for U-shaped buckles, only those with openings facing upward can pass) ensure that each buckle enters the next link in the correct posture. Anti-jamming sensors are installed at the track exit; if a buckle gets stuck, the system pauses and reverses slightly to clear the blockage.

Magnetic or vacuum feeding for special buckles: For thin, flat buckles (e.g., metal decorative buckles in electronics) or those prone to sticking, magnetic conveyors (using weak magnets to separate overlapping buckles) or vacuum suction tubes (sucking single buckles one by one) are used to avoid material accumulation. For large batches, multi-hopper feeding systems can be configured to automatically replenish materials when the main hopper is low, realizing 24/7 uninterrupted operation.

- Positioning Unit: “Finding the Target” Precisely

Buckle assembly requires millimeter-level alignment—if the buckle is offset by even 0.5 mm from the mounting hole, it cannot be pressed in or will be damaged. The positioning unit relies on two core technologies:

Machine vision positioning: A high-resolution industrial camera (16–24 megapixels) captures images of the workpiece (e.g., an automobile door panel) and the buckle. AI algorithms quickly identify the position of the mounting hole and the buckle’s orientation, calculating the offset in real time. The system then adjusts the robotic arm or conveyor to correct the position, with a positioning accuracy of ±0.05 mm.

Laser auxiliary alignment: For workpieces with dark surfaces (e.g., black plastic casings) or reflective buckles (e.g., chrome-plated metal buckles), laser displacement sensors emit a thin laser beam to detect the edge of the mounting hole and the buckle’s height, supplementing vision positioning to avoid errors caused by poor image contrast.

- Assembly Unit: “Pressing in Place” with Controlled Force

The assembly unit is the core of the system, and its key is to control the assembly force—too much force breaks the buckle or workpiece, too little force leaves it loose. Common solutions include:

Servo-driven pressing: Servo motors control the pressing speed (adjustable from 10–50 mm/s) and force (ranging from 20–200 N, depending on the buckle material). During pressing, a force sensor feeds back data in real time; when the force reaches the preset threshold (indicating the buckle is fully seated), the motor stops immediately. For snap-type buckles that require “click-in” feedback, the system can also identify the force drop caused by the snap and confirm successful assembly.

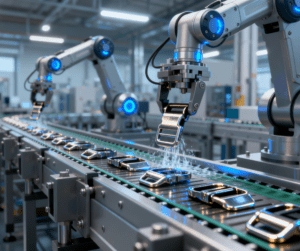

Robotic arm flexible assembly: For multi-buckle workpieces (e.g., a luggage shell with 8–12 buckles), 6-axis robotic arms with interchangeable grippers (vacuum suction or mechanical clamping) can assemble buckles at different positions in sequence. The arm’s flexibility allows it to adapt to irregular workpiece shapes, such as curved automobile instrument panels.

- Inspection Unit: “Final Check” to Eliminate Defects

After assembly, the system conducts two rounds of inspection to ensure zero defective products flow to the next process:

Visual inspection: Cameras check whether the buckle is fully seated (no protrusion), whether there are cracks or deformations, and whether the orientation is correct (e.g., the logo on the buckle faces the specified direction).

Pull-out force testing: For critical applications (e.g., automobile safety belt buckles), a small pneumatic clamp pulls the buckle with a preset force (e.g., 50 N). If the buckle does not fall off, it passes; otherwise, it is marked as defective and pushed into the waste bin. The system records all defect data (type, time, position) for subsequent process optimization.

Typical Application Scenarios: Adapting to Diverse Industry Needs

The automatic buckle feeding and assembly system’s flexibility allows it to meet the unique requirements of different industries, from high-volume automobile production to small-batch luggage customization:

- Automotive Industry: High Beat, High Reliability

Automobiles are the largest application scenario for buckles—each vehicle uses 50–80 buckles (for interiors, exteriors, and chassis). The system needs to match the assembly line’s high beat (e.g., 60–80 workpieces per minute). For example, a domestic new energy vehicle factory adopted an automatic buckle assembly line for door panels: the system assembles 6 buckles per door panel in 8 seconds, with an efficiency 4 times higher than manual work, and the defect rate dropped from 5.1% to 0.09%. It also integrates with the vehicle’s VIN code system to trace each buckle’s assembly data, meeting quality traceability requirements.

- Luggage and Bag Industry: Multi-Specification, Fast Changeover

Luggage buckles vary in size (20–50 mm) and shape (square, oval, D-shaped), and brands often launch new models every quarter. The system’s quick-change modules (replaceable vibration discs, grippers, and vision templates) allow for switching between different buckle specifications in 5–8 minutes. A luggage manufacturer in Zhejiang used this feature to produce 3 models of suitcases on the same line, reducing the number of dedicated equipment by 60% and saving workshop space.

- Electronic Device Industry: Miniature, High Precision

Electronic products (such as tablet cases and wireless earphone shells) use miniature buckles (5–15 mm in size) that require ultra-high precision. The system uses micro-servo motors and high-magnification vision lenses to assemble these small buckles, with a positioning accuracy of ±0.03 mm. For example, a smartphone manufacturer uses the system to assemble buckles for camera modules—any misalignment would cause the camera to be loose, and the system’s defect rate of 0.05% ensures the stability of the final product.

Core Advantages: Creating Tangible Value for Enterprises

Compared with manual assembly and semi-automatic equipment, the automatic buckle feeding and assembly system brings comprehensive improvements in efficiency, quality, cost, and safety:

In terms of efficiency, the system’s assembly speed reaches 15–30 buckles per minute, 2–5 times that of manual operations. It supports 24/7 continuous production without being affected by worker fatigue or shifts, directly increasing the daily output of enterprises by 100–200%. For large-scale production lines, this means shortening the delivery cycle and seizing market opportunities.

In quality, the system’s precise force control and real-time inspection reduce the defect rate from 4–6% (manual) to 0.05–0.5%. Consistent assembly quality ensures that products have stable performance—for example, automobile interiors assembled with the system no longer have abnormal noises caused by loose buckles, improving user satisfaction.

In cost, each production line can save 3–5 manual positions after adopting the system. Considering monthly labor costs, training fees, and rework losses, the initial investment in the equipment is usually recovered within 8–14 months. For small and medium-sized enterprises, this short payback period lowers the threshold for automation transformation.

In safety, the system replaces manual finger pressing operations, eliminating the risk of finger pinching or scratches caused by assembling small buckles. It also complies with industrial safety standards (such as ISO 13849) with emergency stop buttons and safety light curtains, ensuring a safe production environment.

Challenges and Future Development Trends

Despite its obvious advantages, the promotion of automatic buckle feeding and assembly systems still faces some challenges:

Non-standard buckles increase customization costs: Many enterprises use custom-designed buckles (e.g., unique shapes for brand differentiation), which require customized vibration discs, grippers, and vision algorithms. This increases the initial investment and extends the debugging cycle (usually 2–4 weeks).

Material differences affect assembly parameters: Buckles made of different materials (plastic, metal, rubber) have different hardness and elasticity, requiring adjustment of pressing force and speed. For enterprises producing multiple material buckles, frequent parameter switching increases operational complexity.

Looking ahead, the technology will develop in three key directions:

Intelligent self-adaptation: Future systems will be equipped with AI self-learning functions—by analyzing the shape, material, and assembly data of different buckles, the system can automatically adjust feeding speed, pressing force, and inspection parameters without manual intervention. For example, when a new type of buckle is added, the system only needs to scan the buckle once to generate a matching assembly program.

Flexible integration with other processes: The system will be integrated with upstream injection molding (directly receiving buckles from the mold) and downstream bonding or packaging processes, forming a “one-stop” production line. This reduces material transfer links and further improves efficiency.

Green and energy-saving optimization: With the rise of low-carbon manufacturing, the system will adopt energy-saving servo motors (reducing energy consumption by 15–20%) and recyclable material bins, and use low-noise vibration discs (noise ≤ 60 dB) to meet environmental protection requirements.

Conclusion: Small Buckles, Big Leaps in Automation

The automatic buckle feeding and assembly system may focus on “small components,” but it reflects the core logic of manufacturing refinement—even trivial links can become a breakthrough for enterprises to improve competitiveness. As industries such as automobiles, luggage, and electronics continue to upgrade, this system will no longer be just a “tool for replacing manual labor” but a “smart partner” that integrates with the entire production chain.

In the era of Industry 4.0, where precision and efficiency are paramount, the automatic buckle feeding and assembly system will play an increasingly important role. It will help enterprises achieve higher quality, lower costs, and faster responses to market demands, and contribute to the overall upgrade of the manufacturing industry toward intelligence and refinement.