Lanjiu Intelligence Explores the Global Market with Full-Stack Capabilities

As a global provider of full-process smart logistics system solutions, Lanjiu Intelligence Technology Co., Ltd. (hereinafter referred to as “Lanjiu Intelligence”) has built full-stack capabilities ranging from core logistics equipment to system software through more than 30 years of dedicated development. Its solutions are widely used in new energy, pharmaceuticals and other industries, serving benchmark customers such as Lenovo and Shanghai Pharmaceutical Group, while actively expanding into the global market.

In practical applications, smart logistics system providers often face the following severe challenges:

Harsh Operating Environments: Industrial sites feature large temperature differences, heavy dust and strong vibration, imposing extremely high requirements on cabinet protection and thermal management.Delivery Efficiency Pressure: Intense market competition and customers’ demand for rapid production mean on-site installation and commissioning directly affect the delivery cycle.Overseas Compliance Thresholds: Expanding into overseas markets must meet the certification standards of target markets in advance, which is a prerequisite for project implementation.

In response to these common industry challenges, Lanjiu Intelligence has chosen to establish long-term cooperation with Rittal, relying on efficient, reliable and fully compliant hardware infrastructure to support the stable delivery and operation of its smart logistics systems worldwide.

Rittal Solutions

Building a Solid Foundation with Stability, Winning with Speed

The Electrical Technical Director of Lanjiu Intelligence stated:“In recent years, as the requirements for logistics equipment in industries such as new energy and pharmaceuticals continue to rise, our systems need to operate stably for a long time in more complex scenarios. Reliability and efficiency are our key concerns, which is why we choose Rittal cabinets.”

VX25 Cabinet System

Solving Three Major Implementation Pain Points

01 A Stable Foundation in Harsh Environments

Extreme environments are the “invisible killer” of logistics equipment. With an IP55 high-protection design, the VX25 cabinet system resists erosion from industrial dust, liquid splashing and continuous vibration.With a static load capacity of up to 1000kg, it effectively copes with stress changes during long-term equipment operation, meeting the high-reliability demands of the new energy, pharmaceutical and other industries.

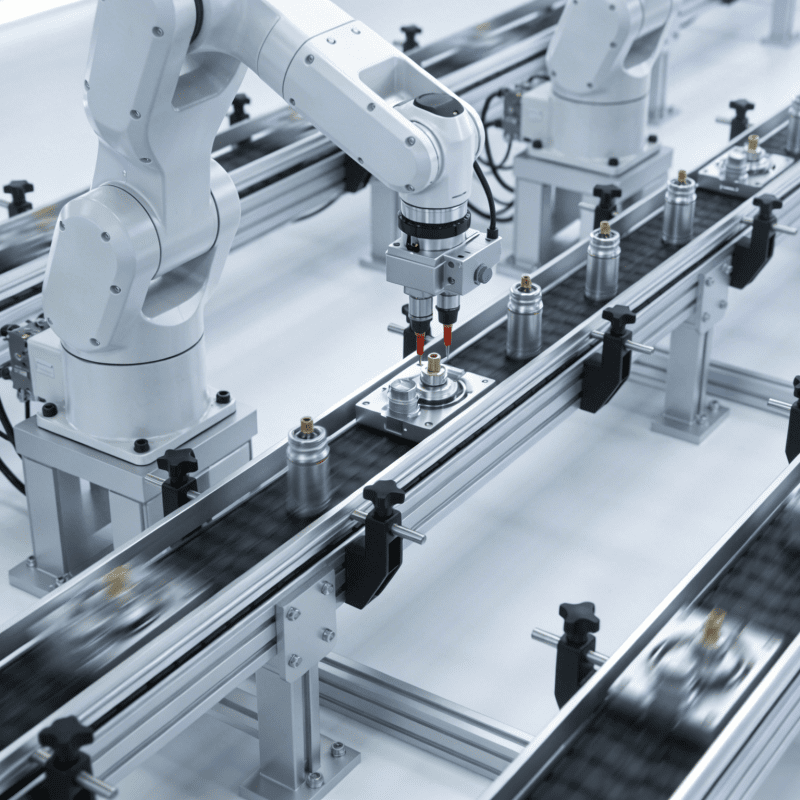

02 Standardization Accelerates Delivery

Faced with urgent production needs, the standardized design of the VX25 cabinet system is key to improving delivery efficiency. Engineers at Lanjiu Intelligence no longer need complex on-site adaptation; they only need to follow standardized procedures for rapid assembly to complete cabinet deployment. The average assembly time per cabinet is saved by up to 70 minutes, significantly accelerating project progress and helping seize opportunities in fierce market competition.

03 Global Certification System Supports Overseas Expansion

The VX25 cabinet system has obtained many mainstream international certifications such as CE and UL, complying with electrical safety standards in the EU, North America and other regions. This means Lanjiu Intelligence can directly use VX25 cabinets as the hardware foundation for overseas projects without additional certification testing, avoiding delivery delays and cost increases caused by certification issues, and accelerating its global market layout.

The Marketing Director of Lanjiu Intelligence stated:“Our project delivery cycles are generally tight, especially for some new energy overseas projects. The efficient assembly of VX25 has significantly improved deployment efficiency; meanwhile, the global certification system of Rittal’s products has also reduced the window risk of overseas projects.”

Blue e+ Temperature Control System

Ensuring Stable System Operation with High Efficiency and Energy Saving

01 High-Efficiency Inverter Technology Reduces Energy Consumption

Adopting an innovative hybrid cooling technology that combines compressor cooling and heat pipe cooling, it saves up to 75% more energy than traditional cooling. It also uses the new eco-friendly refrigerant R-523A (GWP 631), complying with EU environmental standards and enhancing customers’ green competitiveness.

02 Remote Monitoring and Predictive Maintenance Guarantee Continuity

It supports cloud-based remote monitoring and parameter adjustment. The built-in predictive maintenance algorithm identifies fault risks in advance, enabling 7×24-hour continuous operation to meet customers’ extreme demands for system reliability.

03 Flexible Configuration for Complex Scenarios

The cooling capacity of the Blue e+ energy-saving air conditioner series ranges from 0.3 to 5.8kW, allowing customers to flexibly customize according to project requirements for greater flexibility.

Conclusion

True intelligence is not only about pursuing speed, but also about sustained acceleration built on reliability. Through the combined application of the VX25 cabinet system and Blue e+ temperature control system, Rittal has built an efficient, reliable and fully compliant hardware foundation for Lanjiu Intelligence, realizing the implementation practice of “combining speed and stability” and jointly promoting the intelligent upgrading of the logistics industry.

In the future, as Lanjiu Intelligence further expands into the global market, Rittal will continue to serve as its critical infrastructure partner, jointly driving the steady progress of logistics systems on the dual track of efficiency and reliability.

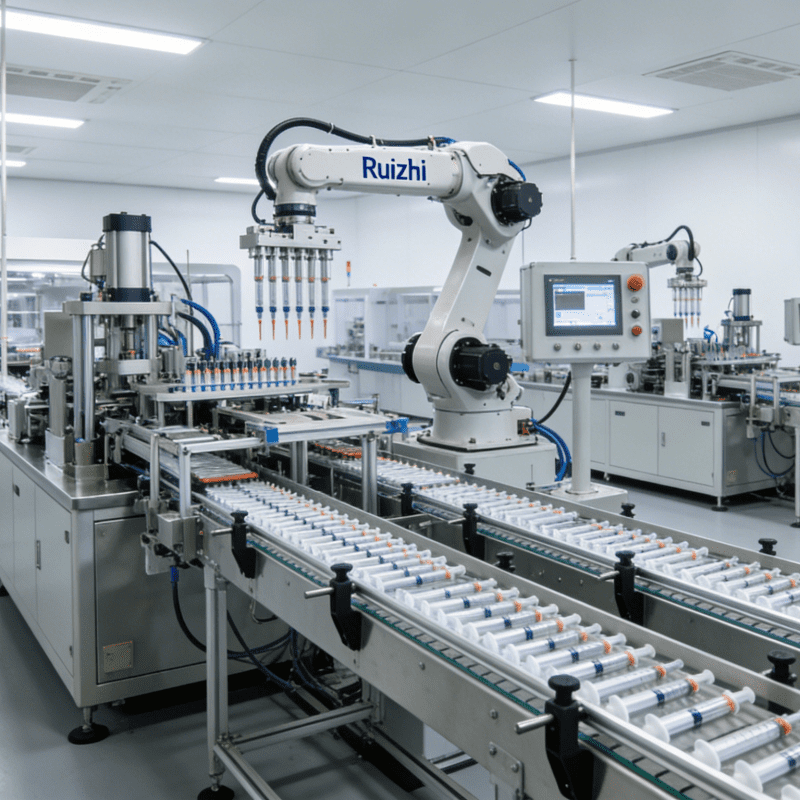

Automated assembly mechanical connection equipment

Artificial intelligence automated assembly mechanical connection robot