Buckles, as essential connecting components, are ubiquitous in industries ranging from automotive and furniture to electronics and luggage. Whether securing a car seat’s safety belt, fastening a furniture panel, or joining an electronic device’s casing, the precision and consistency of buckle assembly directly impact product stability, safety, and user experience. For decades, manual buckle feeding and assembly has been a bottleneck in high-volume production—plagued by low efficiency, poor consistency, and hidden quality risks. Today, the Automatic Buckle Feeding and Assembly System integrates machine vision, precision robotics, and intelligent control to address these pain points, setting a new standard for efficient, high-quality buckle assembly.

- The Limitations of Traditional Manual Assembly: Why Automation Is Indispensable

Manual buckle assembly relies heavily on human dexterity and experience, but its flaws become increasingly glaring as manufacturing demands for scale and precision rise:

Efficiency bottlenecks: A skilled worker can only complete 40–60 buckle assembly tasks per hour. Repetitive motions (picking, aligning, pressing) lead to rapid fatigue, cutting efficiency by 30% in the latter half of a shift. For enterprises with an annual output of 500,000 products, a dedicated team of 8–12 workers is required, with labor costs accounting for 20% of total production expenses.

Consistency issues: Buckles (especially small or irregularly shaped ones, such as automotive seat belt buckles or plastic electronics buckles) are prone to misalignment, incomplete pressing, or even damage during manual handling. The assembly offset often exceeds 0.3mm, and the defect rate due to buckle failure (e.g., loose connections or broken clips) can reach 10–15%. In the automotive industry, a single faulty seat buckle can trigger a large-scale recall, resulting in millions of yuan in losses.

Safety and traceability gaps: Manual assembly exposes workers to repetitive strain injuries (RSIs) from prolonged wrist movements. Additionally, there is no way to record assembly parameters (e.g., pressing force or alignment accuracy) for individual products, making it impossible to trace the root cause of quality issues when they arise.

Technical Breakdown: Core Components of the Automatic Buckle Feeding and Assembly System

A mature automatic system is a synergistic combination of five key modules, each optimizing a critical step from material supply to final inspection:

- Intelligent Feeding Module: From Chaos to Order

The feeding module solves the core problem of “sorting disorderly buckles into a unified posture” and is tailored to different buckle types (metal, plastic, standard, or special-shaped):

Vibration disk feeding (for standard buckles): A frequency-adjustable (25–50Hz) electromagnetic vibration disk drives buckles along a spiral track. The track’s inner wall features custom baffles and notches—for example, for U-shaped plastic buckles, only those with the opening facing upward can pass through, filtering out reversed or deformed pieces. A pre-feeding hopper with a capacity of 500–1,000 buckles ensures continuous supply without frequent refilling.

Vision-guided robotic feeding (for special-shaped buckles): For complex buckles (e.g., multi-claw metal automotive buckles), a 20-megapixel industrial camera captures images of randomly placed buckles in a material tray. AI algorithms identify each buckle’s orientation and position, then guide a 4-axis robot with a vacuum suction cup to pick and place the buckle onto the conveying track in a standardized posture. This eliminates jams caused by irregular shapes, boosting feeding efficiency by 50%.

- Precision Conveying Module: Stable Transportation Without Damage

The conveying module connects feeding and assembly, prioritizing “stability and non-destructiveness” to avoid buckle deformation:

Synchronous belt conveying (for medium-sized buckles): A food-grade polyurethane belt (with a smooth surface and friction coefficient of 0.4) transports buckles at a speed synchronized with the assembly rhythm (0.8–2m/min). Guide rails on both sides of the belt keep buckles centered, preventing offset during movement.

Pneumatic tube conveying (for small buckles): For micro-buckles (e.g., 3mm-diameter electronics buckles), a PTFE (polytetrafluoroethylene) tube replaces the belt. Low-pressure compressed air (0.15–0.2MPa) pushes buckles along the tube to the assembly station, avoiding collision and scratches that often occur with mechanical conveying.

- Flexible Assembly Module: Precise, Gentle Execution

The assembly module is the system’s “core executor,” leveraging robotics and force control to ensure accuracy and avoid damage:

6-axis collaborative robot: With a repeated positioning accuracy of ±0.01mm, the robot aligns the buckle with the product’s assembly slot. The end effector is a custom soft gripper—made of silicone (30–40 Shore A hardness) for plastic buckles or rubber-coated metal for metal buckles—to firmly grasp the buckle without leaving marks.

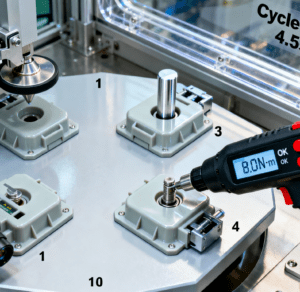

Force control sensor: Mounted between the robot and gripper, the sensor (measurement range 0–300N, precision ±0.1N) monitors pressing force in real time. For example, when assembling a car seat buckle, the robot applies a preset force of 8–15N; if the force exceeds 15N (indicating jamming) or drops below 8N (indicating misalignment), the system pauses and alarms, preventing buckle or product damage.

- Online Inspection Module: Zero-Defect Quality Assurance

The inspection module acts as a “quality gate,” combining vision detection and functional testing to eliminate defects:

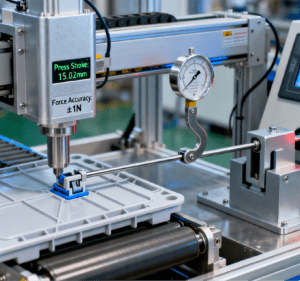

Visual inspection: After assembly, two high-angle cameras capture images of the buckle from the top and side. AI algorithms check for misalignment (offset >0.05mm = defective), missing buckles, or cracked clips, with a detection accuracy of 99.95%.

Functional testing (for safety-critical buckles): For automotive or aerospace buckles, a tensile testing device pulls the buckle with a force of 50–200N (per industry standards). If the buckle loosens or breaks, it is classified as defective and automatically rejected. For electronics buckles, a continuity tester verifies that the buckle’s electrical connections (if applicable) are intact.

- Intelligent Control Module: The System’s “Brain”

The control module, consisting of a PLC (Programmable Logic Controller) and HMI (Human-Machine Interface), coordinates all modules and enables user-friendly operation:

Parameter storage: The PLC stores 150+ sets of assembly parameters (feeding frequency, robot path, pressing force) for different buckle types. Switching between products (e.g., from a furniture buckle to an electronics buckle) takes only 1–2 minutes—workers simply select the preset parameter group on the HMI.

Data tracking: The HMI displays real-time metrics (daily output, pass rate, equipment status) and automatically uploads data to the MES (Manufacturing Execution System). Each product’s assembly record (e.g., pressing force curve, inspection results) is linked to its serial number, enabling full traceability.

Industry Applications: Empowering Diverse Sectors

The automatic buckle feeding and assembly system’s flexibility makes it suitable for multiple industries, delivering tangible value:

- Automotive Industry: Safety and Efficiency

In automotive seat and door panel assembly, the system assembles safety belt buckles and interior trim buckles. A leading domestic automaker reported that after adopting the system, buckle assembly efficiency increased from 50 pieces/hour (manual) to 220 pieces/hour, the defect rate dropped from 12% to 0.3%, and annual labor cost savings exceeded 1.2 million yuan.

- Furniture Industry: Consistency for Mass Production

For flat-pack furniture (e.g., cabinets and sofas), the system assembles plastic connecting buckles. A furniture manufacturer in Zhejiang reduced assembly time per cabinet by 40% and eliminated customer complaints about loose buckles—previously a top consumer grievance.

- Electronics Industry: Precision for Miniaturization

In smartphone and laptop production, the system assembles micro-buckles for casing and battery connections. A semiconductor equipment maker used the system to assemble 2mm-diameter metal buckles, achieving an assembly offset of <0.03mm and meeting strict precision requirements for electronic components.

- Luggage and Apparel Industry: Speed for Fashion Cycles

For luggage zippers and backpack buckles, the system handles high-volume, fast-changing orders. A luggage brand reduced product changeover time from 1 hour (manual) to 5 minutes, enabling it to respond quickly to seasonal design updates.

Challenges and Future Trends

While the system has proven effective, it still faces challenges in complex scenarios:

Adaptability to ultra-specialized buckles: For custom-shaped buckles (e.g., irregularly curved aerospace buckles), feeding and grabbing stability need improvement—current systems may require custom tooling, increasing costs.

Cost barriers for SMEs: A full-set system costs 250,000–800,000 yuan, which is prohibitive for small and medium-sized enterprises (SMEs) with low production volumes.

To address these issues, future development will focus on three directions:

AI-driven intelligence: Integrating 3D vision and adaptive algorithms to enable the system to automatically recognize and adapt to new buckle types without manual parameter setting.

Modular design: Splitting the system into independent feeding, assembly, and inspection modules—SMEs can purchase only the modules they need, reducing initial investment by 40–60%.

Green energy optimization: Using low-power servo motors and energy-recovery vibration disks to cut energy consumption by 25%, aligning with global carbon neutrality goals.

Conclusion: Beyond Automation—A Catalyst for Manufacturing Upgrade

The automatic buckle feeding and assembly system is more than a “labor-saving tool”; it represents a shift from manual, experience-dependent production to data-driven, precise manufacturing. By solving the long-standing pain points of low efficiency and poor consistency, it helps enterprises improve product quality, reduce costs, and gain competitiveness in the global market. As technology advances, this system will become more intelligent and accessible, empowering even more industries to achieve high-quality, sustainable development—one precisely assembled buckle at a time.