In the realm of small-scale manufacturing—where components measure in millimeters and precision is measured in microns—automation demands a unique blend of agility, accuracy, and adaptability. Enter the 4-axis robotic small product assembly system: a compact, cost-effective solution engineered to tackle the intricate challenges of assembling tiny parts, from microelectronics to medical devices. This article explores how these systems are transforming small product manufacturing, their core capabilities, and why they’ve become indispensable in high-precision industries.

What Is a 4-Axis Robotic Small Product Assembly System?

At its core, a 4-axis robotic small product assembly system combines a 4-degree-of-freedom (4-DoF) robot with specialized tooling, sensors, and software to automate the assembly of small, delicate components. The “4-axis” design typically includes:

Base rotation (J1): 360° horizontal movement to navigate across a compact workspace.

Arm elevation (J2): Vertical lifting to adjust height for picking, placing, or aligning parts.

Arm extension (J3): Telescoping motion to reach into tight spaces or varying distances.

End effector rotation (J4): Precision rotation of grippers or tools to orient small parts (e.g., inserting a 2mm screw into a plastic housing).

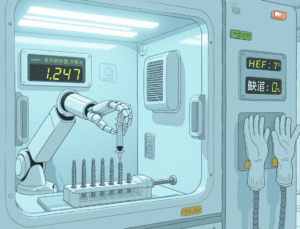

Unlike 6-axis robots—designed for complex, multi-plane movements—4-axis systems prioritize focused, repeatable motion within a fixed workspace. This specialization makes them ideal for small products, where assembly tasks (e.g., soldering micro-connectors, snapping plastic clips, or bonding tiny gears) require consistency over brute flexibility. Paired with vision systems, force sensors, and modular grippers, these robots become a “one-stop” solution for automating even the most intricate small-part workflows.

Why 4-Axis Robots Excel in Small Product Assembly

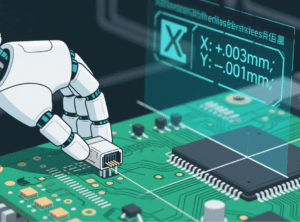

Small product assembly poses unique hurdles: components are fragile (e.g., microchips, glass lenses), tolerances are tight (often ±0.01mm), and workflows are repetitive—all areas where 4-axis systems shine. Here’s why they’re a perfect fit:

- Micron-Level Precision for Delicate Parts

Small components, such as 0.5mm-diameter wires or 3mm plastic gears, leave no room for error. 4-axis robots, equipped with high-resolution encoders and servo motors, achieve positional accuracy of ±0.02mm or better—critical for tasks like inserting pins into circuit boards or aligning micro-LEDs in wearables. Their rigid arm structures minimize vibration, ensuring that even the lightest touch (e.g., placing a 1mg sensor) doesn’t damage fragile parts.

- Compact Design for Tight Workspaces

Small product manufacturing lines are often space-constrained, with workstations squeezed between inspection tools and conveyors. 4-axis robots have a slim profile and fixed working radius (typically 500–1,000mm), fitting into spaces as small as a standard workbench. This makes them easy to integrate into existing lines without costly reconfigurations—ideal for contract manufacturers handling multiple small-product SKUs.

- Speed and Consistency for High-Volume Small Parts

Small products (e.g., USB-C connectors, hearing aid components) are often produced in high volumes, requiring assembly cycles of 1–5 seconds per unit. 4-axis robots excel here: their simplified kinematics (fewer axes to coordinate) allow faster movement, with cycle times up to 30% quicker than 6-axis robots for repetitive tasks. Unlike human workers, they maintain this pace without fatigue, slashing defect rates from 2–3% (manual) to under 0.1%.

- Cost-Effectiveness for Small-Batch Flexibility

Many small products are made in low-to-medium batches (e.g., custom medical probes, specialty sensors), where expensive automation is hard to justify. 4-axis systems solve this: their lower upfront cost (30–50% less than 6-axis robots) and simpler maintenance make them accessible to SMEs. Plus, quick-change tooling (e.g., magnetic grippers for metal parts, vacuum cups for plastic) lets a single robot switch between assembling earbuds, smartwatch buttons, and dental tools in minutes.

Real-World Applications: Where 4-Axis Systems Shine

From consumer electronics to life sciences, 4-axis robotic small product assembly systems are revolutionizing how tiny parts come together:

Microelectronics: Assembling smartphone camera modules, where robots pick 1mm image sensors and align them with lens housings to within 0.05mm. Vision systems guide the robot to correct for minor part variations, ensuring no misalignment affects image quality.

Medical Devices: Building insulin pump components, including inserting 2mm cannulas into plastic bases. Force sensors prevent over-tightening, while sterile grippers (made of medical-grade stainless steel) maintain FDA compliance.

Wearables: Assembling fitness tracker bands, where robots snap 5mm plastic clasps into silicone straps. The J4 rotation axis ensures the clasp locks into place with exactly 0.5N of force—enough to stay secure, not enough to crack the plastic.

Automotive Micro-Parts: Assembling sensor connectors for airbags, where robots crimp 0.3mm wires onto terminals. High-speed motion (up to 1m/s) keeps up with automotive production volumes, while precision ensures no loose connections compromise safety.

Innovations Elevating 4-Axis Small Product Assembly

As small products grow more complex (e.g., foldable phone hinges, miniaturized IoT sensors), 4-axis systems are evolving with cutting-edge features:

AI-Enhanced Vision: Machine learning algorithms train robots to recognize deformed or misaligned small parts (e.g., a warped 2mm plastic tab) and adjust their grip or placement in real time—reducing scrap rates by up to 80%.

Collaborative Capabilities: Safety-rated 4-axis robots (with force-limiting joints) work alongside humans, handling repetitive tasks like inserting screws while operators inspect rare, custom components. This “human-robot collaboration” balances automation efficiency with human judgment.

Cloud-Connected Analytics: Sensors track robot performance (e.g., gripper wear, cycle time variations) and send data to the cloud, alerting managers to maintenance needs before breakdowns disrupt production—critical for just-in-time small-part manufacturing.

Conclusion

The 4-axis robotic small product assembly system is more than a tool—it’s a bridge between precision and practicality in compact manufacturing. By focusing on the unique needs of small parts—tight tolerances, fragile components, and space constraints—these systems deliver efficiency, consistency, and flexibility that manual assembly or over-engineered robots can’t match. As small products continue to drive innovation in electronics, healthcare, and beyond, 4-axis robots will remain the quiet workhorses, proving that when it comes to tiny parts, big precision starts with the right axis.

Axis Robotic Small Product Assembly System

What are the 4 basic robot configurations?